Visualizing mini-split performance data

I’ve been digging through Mitsubishi M-Series performance data for a project I’m working on. I made some graphs of the capacity and efficiency of these ductless mini-split heat pumps. I figured I’d share the graphs here, since many GBA community members are interested in mini-splits.

Take-aways

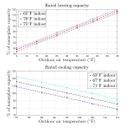

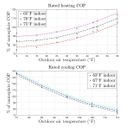

1. Capacity and efficiency depend on the indoor and outdoor air temperatures. (See graphs #1 and #2.)

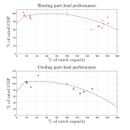

2. Efficiency also depends on how hard the heat pump is working. Efficiency degrades at very low load, when the heat pump starts cycling off and on rather than modulating continuously, and at very high load. (See graph #3.)

3. Maximum capacity is significantly higher than rated capacity. For heating, maximum capacity is typically 150% to 185% of rated capacity; for cooling, 110% to 150%. (See graph #4.)

4. Minimum capacity varies by model. For heating, minimum capacity is typically 15% to 30% of rated capacity; for cooling, 20% to 40%. (See graph #5.)

Terminology

By capacity, I mean output thermal power (in kBTU/h). By coefficient of performance (COP), I mean the ratio of output thermal power (converted from kBTU/h to kW) to input electrical power (in kW). COP is a dimensionless quantity.

By nameplate capacity and COP, I mean the capacity and COP that the manufacturer reports at the specific test conditions of 60 F indoor/47 F outdoor (for heating) and 80 F indoor/95 F outdoor (for cooling). By rated capacity, I mean the capacity measured at given indoor/outdoor temperatures. Rated capacity is less than maximum capacity. By rated COP, I mean the COP measured at rated capacity at given temperatures. Rated COP is usually the highest COP the heat pump achieves at given temperatures. In other words, rated capacity is an efficiency ‘sweet spot’.

Data sources

The primary source is Mitsubishi’s reported performance data, pulled from their 2019 submittals, their longer technical specifications, and/or the NEEP “Cold-climate air-source heat pump specification product listing” spreadsheet. This data is for the 6, 9, 12 and 15 kBTU/h Hyper-Heating models. I focused on this manufacturer and product line mainly because the M-Series is popular, efficient, and known to heat well in cold climates. (Also to keep the project size manageable.) I sanity-checked against Jon Winkler’s 2011 report, “Laboratory test report for Fujitsu 12RLS and Mitsubishi FE12NA mini-split heat pumps”, and various real-world monitoring studies (Roth et al. 2013, Faesy et al. 2014, Ueno et al. 2015, Williamson et al. 2015, Korn et al. 2016, Sutherland et al. 2016). I can share data or link to these studies on request.

Caveat

There isn’t much empirical data on COP while cycling at very low load. The best information I could find was from Winkler 2011, who found in two heating experiments that the 12 kBTU/h model’s COP degraded by 10 to 37% when it started cycling. The lines below 20% capacity in graph #3 are not precise. I’d love to see more data on this.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Oh, another take-away: bigger models are less efficient. (See attached.)

Thanks! Is this just for indoor units or this just one-to-one mini-splits as opposed to multi-splits? I (and my installer) had a seemingly impossible time finding the minimum capacities for heads attached to M-series multi-splits.

My pleasure!

This is just for indoor units paired one-to-one with outdoor units. I haven't looked carefully at multi-splits, for a couple of reasons. Partly to keep the analysis manageable, partly because the minimum capacities on the multi-splits are reportedly pretty high, which can cause cycling and hurt efficiency. But what I've read is mostly anecdotal.

Data I've seen indicates that COP loss from short cycling is < 10%. With little effect on latent capacity.

I believe that the cycling test in Jon Winkler’s 2011 report is very misleading. They actually cycled the power to the entire unit which causes it to start up in high speed mode. This hurts COP. But this isn't what happens when you allow the unit to cycle itself. See "The transient startup behavior observed in the laboratory can explain the high degradation coefficients. "

Chiltrix has told me that they cycle their compressor even when the inverter drive could operate it continuously - because at some point it's more efficient to do so. So buying a HP with lower minimum capacity can reduce efficiency. And it may have no noticeable effect on anything else (eg temp swing, motor life or sensible heat ratio). Short cycling can be beneficial!

>"Chiltrix has told me that they cycle the compressor even when the inverter drive could operate it continuously - because at some point it's more efficient to do so. So buying a HP with lower minimum capacity may actually be harmful."

This is demonstrably the case with some of LG's Art Cool series minisplits that modulate down to ~1000 BTU/hr out @ +47F out, with COPs in the 1.5 range at min-output, less than half the COP at max, looking at the NEEP spreadsheet numbers. At +47F the 3/4 ton LSU/LAN090HSV5 has a COP of

1.50 @ 1023 BTU/hr (min)

5.60 @ 10,900 BTU/hr (rated)

2.65 @ 17,061 BTU/hr (max)

The somewhat comparable Mitsubishi FH09 does quite a better at +47 though it's only modulating down to 1600BTU/hr. That's a higher minimum modulation but at a COP of

4.26 @ 1600 BTU/hr (min)

4.50 @ 10,900 BTU/hr (rated)

3.59 @ 18,000 BTU/hr (max)

I'm sure they could spin it down below 1600 BTU/hr, but I suspect they're trying to avoid the huge efficiency hit if they did.

Given how well the LG performed at 10,900 BTU/hr (5.60 is pretty excellent!) I wonder where the actual COP curve steepens, and whether it would do better if they never let it drop below 2000 BTU/hr.

This suggests that an air to water system with a buffer tank might actually make even more sense from the efficiency side of things. A control algorithm to target 5.60 @ 10,900 BTU/hr for that LG would be a lot easier to target if it was heating a tank of water. I appreciate the higher temp would be a challenge with refrigerant, but it makes the case for the air to water system regardless as you can run the primary loop at max efficiency and then deal with modulation on the secondary.

More support for "cycling has a small effect":

https://core.ac.uk/reader/4822580

Maybe Kevin and Dana, Jon, or somebody could go back and forth and write up an article on this topic, with some recommendations for those of us with less expertise?? Could be helpful for us to select products more optimally and operate more efficiently.

Hopefully folks are still monitoring this:

I represent an electrically constrained townhouse. We have about 22 amps we can allocate to a heat pump. I've got a graph of actual measured gas consumption over a period where outside temperatures averaged -6. I'd like to roughly illustrate, how much of their home heating in this situation could be replaced by a low powered heat pump, I've posted my graph here, using the Mitsubishi MXZ-3C24NA3 as an example. What I am not clear on is whether I should use the "rated capacity" value of 14,600 BTU/hr OR the "Maximum Capacity" value of 19,600 BTU/hr. Those values are from the Submittal sheet for Heating Capacity at 17F (-8.3C).

I want us to make an informed decision on whether there is sufficient value in upgrading our electrical supply in order to eliminate gas heating for 4-5 days a year. Or if it makes more sense to divert those reasources to improving energy performance. (Sounds like a retorical question, but trying not to be biased here!). All units have a gas fireplace in addition to a gas furnace they could use to suppliment heating.

You would want to use 'max', not 'rated'. 'rated' runs the compressor at a fixed speed for 'official' testing, but 'max' represents the true output (and therefore the true load).

Curious why aren't you looking at at HyperHeat unit instead?

thanks for answering that question,

about Max rated vs Rated.

sometimes there is quite a difference. Which I don't understand why.

for example

The hyper heat model:

SVZ-KP18NA & SUZ-KA18NAHZ by Mitsubishi

‐4°F Max BTU = 16,116

‐4°F RATED BTU = 5,557

Screen shot attached.

Data sheet here:

https://www.mitsubishitechinfo.ca/sites/default/files/SB_SVZ-KP18NA%20%26%20SUZ%E2%80%90KA18NAHZ-TH_202209.pdf

As I said above, 'rated' runs the compressor at a fixed speed for official testing, that is lower than it's max speed. That's why it consumes less power and puts out less heat.

Max is with the compressor running as fast as it can, which produces more heat but consumes more power.

Thank you.

I was thinking about the inverters and how they "modulate",why can't these heat pumps modulate to reduce cycling on and off.

I.e. max rated 16kbut,

Design load at same -19C temperate is 16k BTU or maybe even higher say 20kBTU.

Why can't the split systems (ducted) modulate down to give you the required output needed?

Currently I am monitoring the electrical input to a LG heat pump, (LV181HV4) and it always starts of high (2kw,) then goes down to (1kw), doesn't matter what the outdoor tempertute is.

"why can't these heat pumps modulate to reduce cycling on and off."

What are you asking? These things do modulate.

Each unit is going to have it's own control strategy. The system needs to worry about managing refrigerant, oil, defrost, etc. This doc from Mitsubishi on the MXZ systems would give you some idea of how they operate: http://s3.amazonaws.com/enter.mehvac.com/DAMRoot/Original/10006/Application%20Note%201040%20ME%20-%20MXZ%20Sequence%20of%20Operations.pdf

Perfect, thank you!

I need to keep my maximum current draw down. Also, this is Vancouver BC, the record low here is -15C. The stretch, where it averaged -6C lasted 4 days and haven't had a daytime high below freezing since.

The MCA on the Hyper heat models are 8 amps higher on the MXZ-3C24NA3 model and 12(Why?!) amps higher on the MXZ-2C20. Due to lack of logging capabilities on our meters we need to base our sizing off the Canadian Electrical Code, and it requires us to consider the worst case loading conditions. Fujitsu is kind enough to post actual Max current draw values on their data sheets. According to official Mitsubishi literature, MCA IS the max current draw.