Wall assembly for new home near Vancouver Canada, and is GUTEX wood fiber insulation recognized as a WRB by code?

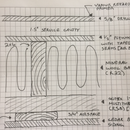

We’re finishing up the plans for a new home outside of Vancouver, Canada. My proposed exterior wall assembly is shown below. GUTEX wood fiber insulation serves as the WRB, interior plywood with taped seams serves as the air barrier, and vapour-retardant primer on the drywall serves as the vapour barrier. There would then by no poly or building wrap. I might be able to eliminate the service cavity for all walls with windows–to minimize window frame depth–as there are only ~3 outlets in total on such walls.

Questions:

1. Is this extra insulation pointless, as my home has a lot of windows (see image here: https://www.greenbuildingadvisor.com/question/big-low-sloped-mono-pitched-roof-vented-or-unvented but note that the non-lake facing sides have much fewer windows)?

2. Is the GUTEX wood fiber insulation recognized by code as a weather-resistant barrier?

3. Is this a reasonable insulation plan for my region?

4. I know the GUTEX is expensive, but I’d rather pay more for materials and less in labor cost. This wall doesn’t seem _that_ much more complex to build than a conventional 2×6 wall. True or false?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Peter,

I'm sorry I don't know if Glutex has the necessary approvals or not. A few comments on your wall assembly:

- With that large amount of glazing you are out of the code prescribed Braced Wall Bands. What is your engineer using for shear-walls? That may affect your proposed wall assembly. The space between the windows will probably be Simpson shear-panels, which come in specific depths that might not match your stack up.

- Why 1"x4"s for the rain screen battens? Most builders use the 1 1/2" wide pre-cut plywood strips available in all lumberyards.

- What is going in the service cavity? It is too narrow for plumbing, standard electrical boxes, and you can't run wire through the framing as there needs to be 1 1/4" clear from face of stud to edge of hole.

Thanks for the reply, Malcolm!

> With that large amount of glazing you are out of the code prescribed Braced Wall Bands. What is your engineer using for shear-walls?

The preliminary drawings I've seen so far from the engineer specify certain walls as shear walls with 1/2 plywood (which I assumed could go on either side of the wall) and there are beams above those big runs of windows. The engineers are still working on the finalized drawings, so there may be more to it that I don't understand.

> Why 1"x4"s for the rain screen battens? Most builders use the 1 1/2" pre-cut plywood strips available in all lumberyards.

I just guessed at what was normal (I'm a physicist, not a builder, and I haven't run this past anyone but you guys yet). So yeah the pre-cut plywood strips probably make more sense.

> What is going in the service cavity? It is too narrow for plumbing, standard electrical boxes, and you can't run wire through the framing as there needs to be 1 1/4" clear from face of stud to edge of hole.

Wire to electrical boxes and one light switch. I thought 1.5" was the minimum to make this fit (and that low-profile boxes existed). I guess the service cavity needs to be deeper to be useful, as you pointed out, which also isn't a problem.

Thanks for the help!

Peter,

They were more just things to look out for.

The plywood rain-screen battens save a lot of time and materials, and also leave you with more cavity an less batten. they work well with the pre-formed perforated J- shaped base-flashings most lumberyards also stock.

Service cavities are one of my bugbears. They seem like a good idea, but often don't contain enough services to justify their inclusion. I think they make sense when they hold ducts or plumbing on exterior walls. but for a couple of outlets and switches, using air-tight boxes makes more sense to me.

It looks like a really nice house! Good luck with the build.

Good point about the service cavities being of questionable value. There really isn't a lot being run in them!

Although not required where I'm building, I'd like to do a blower door test as early into the build as possible, and try to minimize air leakage to passive house standards. To me, intuitively, it seemed like having a well-defined air barrier on the inside (as plywood with taped seems) would make sense, especially if the GUTEX boards eliminates the need for exterior sheathing. I guess the downside of getting rid of the service cavity is that an electrician needs to wire at least the exterior walls before you can do the blower door test, but I suppose that's doesn't really complicate scheduling if it's just a handful or two of outlets and one or two light switches.

I don't know much about the practicalities of blower door testing. If you did wait until the interior plywood was on and taped, and all the services installed, wouldn't that be a good time to test, so you still had the chance to remediate leaks, but also no more penetrations were going to be made in the air-barrier?

What I particularly like about your design is the covered outdoor living areas. They are great spaces in our climate - and yet so rarely included in houses here.

The relevant tests for WRBs are what make up AC 38 - https://icc-es.org/acceptance-criteria/ac38/.

Since I don't see this listed anywhere with Gutex, I am presuming that while it may indeed qualify as a dedicated WRB, Gutex does not have this approval considered the "bar" for our building codes.

HOWEVER, every building code in the US has a section in Chapter 1 - Scope and Administration entitled Alternative materials, design and methods of construction and equipment. Any code official can use this section to consider alternative materials that, to hime or her, satisfy the code in terms of "quality, strength, effectiveness, fire-resistance, durability, and safety."

Peter

>"HOWEVER, every building code in the US has a section in Chapter 1 ..."

You may have noticed that Vancouver is NOT in the US, making the NBC far more relevant than the IRC. I'm not sure what comparable sections of Canadian or local B.C. codes might apply.

Regarding suitabilty as a WRB, SONOclimat ECO4 (manufactured in Quebec) is in many ways comparable to Gutex, and seems to be used a WRB in some installations, not in others. The short-sheet assembly instructions refer to section 9.25.3 of the NBC, which is about air tightness of the assembly, not weather resistant barriers.

https://www.mslfibre.com/Upload/Documentation/G12670-103_Sonoclimat_ECO4_EN14636555989334640938.pdf

https://www.mslfibre.com/Upload/Documentation/T12670-106_SONOclimat_ECO4_En_08-14636585404223102286.pdf

In some PassiveHouse type houses using SONOclimat ECO4 people seem to be using fully adhered permeable WRB such as BlueSkin (probably for it's air-sealing aspects rather than as a WRB). Other high performance houses in Canada have used it as exterior sheathing sans WRB.

I would expect Gutex to be similar, but whether the NBC would require a particular test to use it as the WRB is beyond me. I would also expect SONOclimat ECO4 to be cheaper than Gutex in Vancouver, and may be sufficiently structural to use at structural sheathing, saving the cost of the half-inch plywood.

SONOclimat ECO4 is manufactured using a different process than Gutex ("wet" vs "dry") and does not have the same integral paraffin wax as a water repellent that Gutex Ultratherm or Multitherm have; a separate WRB must be used with SONOclimate ECO4. (Gutex manufactures different products with different characteristics, as does MSL Fibre, manufacturer of SONOclimat ECO4).