What works for noise reduction in the party wall?

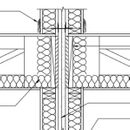

I am curious what the building community would recommend for reducing the noise in between two townhomes? The house is built to the Passive House standard, so the exterior noise to the duplex will already be substantially reduced. It seems that it would be a pity to hear the neighbors TV, or something like that. At this stage, the choices might only be between specialty insulation or specialty drywall, or nothing (?), given that the framing is finished. I attach the picture for the party wall section. Without insulation and drywall, we can hear each other talking at a moderately loud level between 2 units (across 2 party wall shaftwall boards+gap). Our default design is to finish these walls with 5/8” drywall and insulate with 3 1/2” of fiberglass bats. I looked up Certainteed products like SilentFX “SilentFX¯, featuring M2Tech¯ technology, is a noise-reducing gypsum board specifically designed for systems requiring high STC ratings where acoustic management is needed. Viscoelastic polymer is applied between two specially formulated gypsum boards to dampen sound energy and significantly improve sound attenuation through walls and ceilings” – does anyone have experience with this or similar products..?

Thanks,

Lucy

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Wow, that is not good that we have an acoustical flaw in the design. We cannot get rid of this shaftwall system anymore - all the air sealing effort to reach Passive House went into that, etc. So, it sounds like we should invest in the improvement on the drywall side, either Green glue or SilentFX or similar... I'm mu ch more motivated now after hearing this feedback.

Thanks,

Lucy

I have worked on duplex's with noise concerns. There is one major glaring mistake on that diagram for noise control. The drywall placed in the center of the two double walls is a major no no in noise control. Called the triple leaf effect. That particalar drywall placed their will transfer noise between the units.

Even adding 5/8 drywall on the outside of the double wall in the units will not help in of themselves because of the interior drywall placement. Also sound control insulation does not control sound better than even the cheapest fiberglass matts. Having the insulation their does help and should be included, but don't think you'll get any more db reduction for using sound control insulation verses the cheapest insulation.

I would get rid of that board between the units. Have 5/8 or 1" drwall on the two outwalls leaving a dead space with insulation between the units. That alone will drop the noise level from around 30 db to 52 db noise reduction. That would also be within fire code.

The more expensive option is using green glue which really does work. Take two tubes of green glue per 4 x 8 sheets (around 15 dollars per tube at menards, etc...) and then add another sheet of drywall. Around 40 dollars per 48 square feet per side of the outter wall in materials, not labor included. The Green Glue makes sound waves into heat energy. After a couple weeks you'll see similiar results of around 52 db reduction in sound transmission.

Because of labor Certainteed makes Green Glue but also the drywall sheets with built in sound control. I believe its around the 55 dollar per sheet. Might be able to get it cheaper in bulk. Similiar results as the green glue. Also they make sound clips that isolate the vibrations between the units.

What ever system you use make sure all outlets have sealed baffles so you don't have sound flanking between the units as well.

Lucy,

A recent Q&A thread on GBA included two responses that recommended this NRC Canada web page as a good resource for sound reduction methods:

http://www.nrc-cnrc.gc.ca/ctu-sc/category/st

NP. Sound control is so important in a multi unit and so hard to get to a acceptable level. Good luck. Looks like the air sealing is done well and seperate floors, so sound flanking shouldn't be a problem at least.

Stephen

Lucyna,

SE has effectively covered the bases. It's counter-ijntuitive, but the gypsum in the centre of the wall makes any sound attenuation a lot harder. An asymmetrical build-up would definitely help: Two layers of drywall on one side and resilient channels on the other. Green glue, mass loaded vinyl - all sorts of solutions, but none of them yielding predictable results without modelling. If it's important to you I'd hire an acoustical consultant.

Lucyna,

Even though it is against the conventional wisdom I think there can be a difference in sound isolation between different insulating materials. I have had dense packed cellulose installed in both my previous home and my current home. In both cases sound coming from the street was drastically reduced after the installation. In my current home my bedroom has a wall only 10 feet from a well traveled street. Although I still hear the traffic it has been reduced to just a very slight background noise. This sound without this attenuation is much louder than any unattenuated noise from neighbors would be.

This can be understood intuitively I think. One advantage dense packed cellulose has over many other kinds of insulation is that it very effectively reduces blower door leakage rates in an otherwise not very tight house. Sometimes those blower door leakage rates in a house like that can be reduced by 75%. I don't have the article or statistics at hand but I do remember reading that somewhere. So it would make sense that it might have a similar sound suppression effect in a wall shared by neighbors by reducing all those micro channels where noise would normally channel through.

One more thing if you contemplate using cellulose. It's cheaper than the professional acoustical solutions and will insulate in addition, just like fiberglass batts. You can also see if the sound suppression meets your needs after you dense pack the wall but before you put up the drywall. If it does, and it probably will, then it negates all the need for acoustical drywall or green glue. But you can still go that route in addition if you decide to.

Eric- if acoustic isolation is the goal you DON'T want to dense-pack, since that increases the mechanical coupling between the tympanic surfaces. Dense packing is somewhat more air-retardent than low density cellulose, but that factor alone isn't sufficient to make up for the firmer mechanical coupling.

The reason rock wool sound deadening batts designed for 2x4 construction are typically 3" or 3.25" thick rather than the full 3.5" is to eliminate the direct mechanical coupling via the batts themselves. The same principles applies to blown fiber, but with blown fiber you can't size it to less than a full fill. The only factor you can really control is how firm it is, and less is more. Blown cellulose is still fairly air retardent at low density (unlike fiberglass), making it a pretty good choice for low-density fiber sound abatement.

Eric, You are right, but it doesn't go against conventional wisdom. The differing sound attenuation properties of various insulation types are tested and the results are available from the manufacturers and third parties.

The problem with partially testing a wall then completing it is that the remaining materials can actually reduce its performance. That's what in general it's best to replicate an assembly that has been tested as a whole and has predictable results.

A good example of this is adding a layer of strapping (or resilient channel) and drywall to an existing finished wall. It almost invariably reduces the effectiveness.

Dana, I understand what your are saying but my experience in both my homes with cellulose just does not agree with that analysis. I think the reason may be, though I'm not sure, is that cellulose is compressible and has a fairly high mass to volume compared to some other insulations. For a sound to be transmitted you have to not only vibrate the drywall itself but you also have to move the very small fibers of cellulose that are touching. That high mass to volume seems to damp those vibrations very effectively from my admittedly subjective, but consistant experience.

Malcolm, yes I agree that there should be a difference in sound suppression between one with drywall touching the insulation and one without. But I don't think it's as clear cut in this case that one situation is far better than the other. One would simply have to do the testing to see. Maybe someone already has. I just don't know. I just know that cellulose was NOT isolated from my drywall in both my homes and it was still effective in sound suppression. Whether it would be more effective with strapping separation is a good question. And would it be significantly different or not? I think the mass of the cellulose over a BIB fiberglass type might make a difference, but don't know.

Eric: Have you in-fact used 2lb cellulose and compared it to 3.5 lb cellulose in the same / similar walls? (I've seen some test data from a decade ago, but can't seem to lay my hands on it quickly...)

When the shaft wall system was selected, we were guided by the manufacturer indicating up to 60 STC rating for this party wall system. I re-read the brochure (http://www.usg.com/content/dam/USG_Marketing_Communications/united_states/product_promotional_materials/finished_assets/usg-area-separation-walls-catalog-en-SA925.pdf). They indicate 60 STC with sheetrock gypsum in the middle, if 3'' of mineral wool batts are placed on each side. Empty cavities would give STC rating of 46. We have R-13 fiberglass batts there, filling the cavity full. Could anyone indicate what our resulting party wall STC might be, roughly...?

Dana, well that wouldn't work very well for me. I tried to get at least a minimum of 3 lb per cubic foot everywhere and think I succeeded. If I hadn't it would have slumped over time and created much bigger problems, including cold and sound coming through the areas above where it had slumped.

Lucyna,

After reading the brochure you referenced it looks to me like the middle two layers of sheetrock is required for fire suppression and with the metal acting as a "fuse" so in case one side collapses it does not bring down the other. You should not consider that a flaw in sound suppression but serving as a much more important role in protecting life and property. So forget the previous concern here about that causing problems with sound suppression. It's required (or should be).

I saw only one place in the brochure where it mentioned a 60 STC and the place I saw it did not specify how to get it. The rockwool is not a sound suppression decision but a fire suppression decision. It's probably the best insulation for that purpose. Don't ever use foam in that space. But other insulations will work equally well or better for sound suppression purpose as rock wool. I believe cellulose is the best for sound suppression, but that is my opinion from my own experience. It will not serve quite as well for fire suppression as rock wool but will still not burn readily because it is treated with borates for that purpose.

The main thing is not to get confused between implementations advised by USG for fire suppression and those for sound suppression. The big majority of information in that brochure is for fire suppression and they are generally unspecific on how to get the maximum sound suppression.

Eric,

Forgive me, I probably wasn't clear. Installed the same way different insulations offer different sound attenuation results. For instance, rock wool, such as Roxul's Safe and Sound, performs much better that fiberglass batts of the same dimensions. That's why it's often specced in party walls , not as part of the fire rating of the assembly.

My main point os that assembling a wall out of various components ad-hoc, doesn't alway add up to a very good result. The most predictable results come from replicating assemblies tested as a whole. Our code contains lots of them as does the NRC site.

Lucyna,

Unfortunately that wall assembly lacks basic sound attenuation components and will perform pretty poorly. There is no de-coupling of any of the components. De-coupling is usually provided by either resilient channels or resilient sound isolation clips. It is also symmetrical, meaning that it may not dampen sound at all frequencies. It needs to be modified if you want it to perform at an acceptable level.

If you look at page 9 of the brochure it tells you what you need to do to get specific stc ratings. The center gypsum it also separated/ decoupled from the structure by a min 3/4" gap and it is all held up by the clips. I would recommend Roxul over fiberglass if you want the ratings listed in the brochure.

Jeremy, yeah I missed that.

Hate putting a manufactured site here, but the data is independent and very detailed for different wall asemblies. http://www.greengluecompany.com/test-data. Not the only good source of info, but a good start. Also not the only company making great sound proofing, but it works for me. Also lower any figures on db in light of the double layer in the center of the assembly.

Stepen

Could anyone help interpret the brochure NoiseControlDesignGuide.pdf from Owens Corning? In it I find a table for acoustical properties for fiberglass batts, and indeed, specialty sound attenuation batts and regular building insulation batts have similar parameters for 3 1/2'' batts. But for FRK faced, the parameters drop significantly. Does "FRK" include Kraft backing? I put a call to Owens Corning, but there is a potential 24 hr delay to get technical help like that. In the meantime, we stopped the installers from putting EcoTouch with Kraft backing. We want to change to mineral wool for the second side of the party wall. Could it be that this EcoTouch is acoustically worse than unfaced fiberglass batt? Another question: installer may have 3/1/3'' mineral wool 24'' (o.c) readily available, but not 3'' with 24'' widths. Would 3 1/2'' be acceptable or do we need to get 3'' (on a 2x4 wall) to create separation between mineral wool and drywall?

Life is never simple...