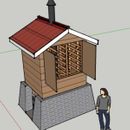

Wood-fired dehydrator

Here is a concept for a wood-fired food dehydrator I came up with.

When I was looking for ideas there didn’t seem to be much information available.

This idea is based on an article I read that described something like it in use in an orchard.

I wonder if there are ways to make it work better without making it any more complicated?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Some details...

The idea is for the wood-burner below to heat the rubble fill.

Convection dries the stuff inside.

I think leakiness might be an advantage here.

I wonder if the openings through the rubble fill and the exhaust at the ridge vent will allow for the best possible convection current?

I don't think I would run the stovepipe inside the dryer as that will create a very uneven heat distribution. But I would probably try to come up with some way to use all that heat for other purposes, such as domestic hot water or an attached sauna.

Good point. Getting the stovepipe outside would make more room inside for racks too.

If the wood-burner was a barrel stove and the stovepipe came out the back horizontally, through the foundation, then vertically up the outside of the shack, would that ruin the chimney draft do you think?

Rules of Thumb for Chimney Height

The minimum overall height of any chimney system is 12 feet for a vertical chimney with no offsets at sea level.

To compensate for:

One Tee Add 3 feet to the minimum height.

One 45° Elbow Add I feet to the minimum height.

One 90° Elbow Add 2 feet to the minimum height.

Each foot of horizontal run add 2 feet to the minimum height.

Each 1000 feet above sea level add 4% to the minimum height.

Chimney flue cross sectional area no more than 25% larger than connector pipe (stove outlet).

Total connector pipe length no more than 75% of chimney height above thimble.

Total connector pipe length no more than 10'.

Horizontal connector pipe runs should be short and pitched upwards at ¼" per foot.

No more than two 90° elbows in connector pipe.

15' minimum chimney height above woodstove.

Chimney termination at least 3' above highest point of roof penetration.

Chimney termination at least 2' above anything within 10' laterally (including tree crowns).

However,

Those rules for minimum chimney height are not relevant if you're running the woodstove wide open and very hot, since draft pressure is dependent on temperature difference (flue to outdoors) as well as height.

My hot tub is burning right now quite nicely with a 6' chimney (just flue connector pipe), since it always burns wide open, often with flames shooting out the shanty cap.

Lucas,

That's a commercial-scale dehydrator, and a big investment to build. How much produce are you drying?

I've had good luck using metal racks above my wood stove in the fall -- using the same wood stove I cook on and heat with. I also hang things from the ceiling joists above the stove on thin wire -- red peppers, garlic, and apple slices. It's a lot easier to monitor the drying if it's in your house.

But if you are running a commercial farm, you need a big unit.

Robert, thank you.

I have printed your rules of thumb for future reference.

I love it when I can print something for future reference ;-)

Martin, thanks for your input.

My main interest in building a larger wood-fired unit is for apples. My own small orchard is still quite young and not bearing yet but in the mean-time I'm lucky to have several neighbours with many large, productive trees and no apparent interest in collecting the apples (I think it's their age or maybe the bears). I've been collecting these apples and I thought it would be nice if I could dry them and share them around.

I already have about 90% of the materials lying around in my yard - I put out adds on the local buy-and-sell website for people's unwanted materials then pick them up on my way to work.

I must confess I never thought about drying in the house... This would be a more appropriate method for my garden produce.

Is your house "tight"?

Have you had any problems with RH when you are doing your drying inside?

Does it take long to dry your produce indoors?

Lucas,

Sadly, my house is not tight. As the saying goes, "the cobbler's children are ill-shod."

When I used to boil maple sap indoors, I would fog up the windows. But dehydrating apples has never had that effect.

The length of time it takes to dry apple rings depends on whether you are using your wood stove daily or not. Some varieties of apples need to be harvested in late August, when the wood stove is rarely used. Other varieties of apples can be harvested in early November, when the wood stove is running all the time.