Hydronic Heat Retrofit

Greetings,

We are renovating an Eichler style midcentury home in zone 6B. It’s a 2,700sq ft ranch with 1,000sq ft basement. Right now it’s using two furnaces 150,000btu and 90,000btu. Way oversized. For the sake of this conversation:

-Walls are currently 2×4 R8, we are retrofitting a double-stud wall with midwall air/vapor barrier. R32

-Ceilings were a mix of drop and sloped, we are removing the drop ceilings to reveal the sloped 2×6 rafters and insulating with R21 batt. We’re adding 4″ of polyiso to the deck so the total roof r value will be around R45

-Floor joists are 2×10 16″ o.c. , basement ceiling height is only 7’8″ (once I remove the furnace plenums). The goal of this project is to maintain ceiling slopes and heights. Unfortunately it doesn’t leave room for new duct work.

-Approx 350sq ft of the home is a sunroom that we are converting to living space. It’s got nearly 450sq/ft of glass probably a heat load of 12,000btu/h.

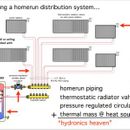

Because the ceilings and walls will be open (and the water heater needs replaced) it’s a good candidate a hydronic retrofit. I understand the heat load is important. I believe it will be around 35,000 btu/h. By the time this gets ordered/installed we’ll have a heat loss calc. It’s critical that the system is as simple as possible. From the get go I assumed wall radiators with TRVs, home run, and a HTP phoenix light duty water heater (for those unaware it’s a modulating, condensing, tank water heater with internal heat exhanger). I like that it’s mechanical, zoned, and straightforward. The phoenix water heater and TRVs appear to drastically simplify the system. I’m now considering using radiant walls or ceilings so that the heating is concealed. The sunroom conversion will be built over slab so we could go radiant in that floor to help cover the load.

Fabbing the wall or ceiling panels is straightfoward to me, but I am confused on the ability to maintain control of the panels with a TRV. Searches along heating help and others suggest the loop length needs to be kept down and suggestions for an Oventrop unibox. Can someone help me understand how a TRV would install in this application?

What do you do around electrical outlets with the heat transfer plates on radiant walls? Is there a clearance requirement? For example, if the outlets required 1′ clearance on all sides I may go with the ceiling for the easier install.

Long story short. I think hydronic heat retrofit is the best fit all things considered on this project. I’m prepared to go HTP Phoenix with radiators on TRVs. I’m willing to put the extra work into concealing the system into ceilings or walls, if I can maintain control with the TRV. Any thoughts?

Thanks,

Brandon

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I remodeled a two story using warmboard...which can be installed on floors or ceiling. It is speedy but very comfortable. Heat for house comes from a 80 gallon hot water heater that runs through a heat exchanger that brings the temperatures down to 85 to 103f. We conditioned our attic with 2 inches of closed cell foam and 16 inches of some fiberglass which really lowered the heat loss. Your idea of using a water heater is good.. in terms of the TRV, I just used manifolds, a zone controller and some Nest thermostats.

"Speedy"= spendy?

I assume "TRV" is thermostatic radiator valve?

The usual way to use them is you have one zone that doesn't have a TRV but has the system thermostat. The thermostat controls the circulator. The other zones open their TRV if they need heat. In order for this to work the thermostat zone has to be undersized relative to the others, so that it runs more often, so that when the other zones are calling for heat the pump is likely to be running. This is not going to give you as fine control as having a thermostat in each zone.

I don't see why you couldn't use a TRV with a radiant loop, you'd just have to figure out a way to mount the TRV where it can sense the ambient temperature.

I don't associate radiant wall heat with "as simply as possible."

I haven't done wall panel, but the way I would approach it is to have a mixing valve at the tank to set the max temp for the panels and run the TRV as normal. Mount them a bit away from the panel so that they pick up room temp not panel temp or use one with a remote sensing bulb.

With a tank type heater, you don't need any thermostat, but you should use a delta P circulator. The power use on these dead ended is so small that it is not worth adding a thermostat to shut them off during the heating season.

Note, the standard HTP light duty is meant for combi heat, not space heat. This means open system with short pipe length limits in most jurisdictions. There is the solar version of it that has an internal coil which you could use for space heat feed but I think located in the bottom of the tank, which will limit the amount of BTU you can get out of it. I would check with the manufacturer first.

I would do ceiling rather than wall. People put furniture against walls, and there are gaps for windows, whereas you can cover the whole ceiling, although with your upgraded insulation, if you also air seal well, you won't need that much heat delivery anyway, and you might be able to do a small area of the ceiling.

I see no reason you couldn't use TRVs on a wall or ceiling. The trickiest part would be mounting them in a way that doesn't look out of place. However, a more standard approach would be to use electrically actuated zone valves. Some zone valves consume significant electricity, but Taco has some that only use electricity for a short time during the transition from off to on, and probably others have similar now too.

I recommend hiring a good hydronic designer. There are lots of subtle ways you can screw it up if you don't have experience. I know because I designed my own system in collaboration with a plumber. Between the two of us, we did better than either would done alone, there are still mistakes that an experienced hydronic designer would have avoided.

You might want to consider going to a heat pump system: that would enable you to get off fossil fuels and if you use large area emitters like ceiling panels, that would enable the use of low-temperature water that a heat pump can produce efficiently.

High performance windows in that sunroom should be able to drop that load to maybe half of the 12,000 BTU/h you estimate, and make it more comfortable on a cold day as a bonus.

Thank you for your replies I'm sorry I didn't catch them sooner. I reached out to BlueridgeCompany who will do the heat loss and design. They prefer radiant floors and tekmar/taco control. If I go that route it's going to be a top of subfloor retrofit. The house's current subfloor is 1x8 diagonal boards with 5/8" plywood over it so I don't think radiant underneath would be as efficient. We're going with a LVP flooring product that should be able to install directly over the transfer plates/subfloor infill.

It boils down to finding someone to design the system and spec the components. I don't have enough knowledge or confidence in my subs to deviate from a plan or form one on my own. I trust Blueridge.

Akos I appreciate the heads up on the phoenix LD. The units run roughly $2500 in my area maybe I can substitute a boiler with indirect tank for the same cost without the limitations.

I'm in SE Wyoming the natural gas is very cheap compared to electricity. The heat pump would not be a good fit at this time, but I wish to design with lower water temps so I can retrofit with the heat pump when costs are lower and better cold climate options. I had Arctic spec a system on a new construction house about 9mo back. In the lower temps you really need to rely on a back-up. They have backup elements in their buffer tanks but it would cost a fortune to run the electricity.

Charlie, that's triple pane glass. .28 U-factor. Nearly 450 square feet of glass in the sunroom. My design temp is -1. I think a ton load for that room is close and the whole house likely around 3 tons.

Thanks

Triple pane should have a U-factor more like 0.2 rather than 0.28, assuming low-e and argon (which are both cheaper to add than triple-pane so I assume it has those.) Either that's with a very poorly insulated frame (which would be a concern for condensation problems as well as cost of heat) or it's a mistake somewhere.

Have you considered a high velocity hot air system which uses small ducts. These would fit in your 10" joist bays.

I assume you mean hi-V with hydro coils?

Yes, that is correct. I use one in part of my house and it works well.

I was mistaken the windows are double pane. Thank you for pointing that out Charlie.

I haven't considered the high velocity hot air system. I'll look into it.

Thanks

Why are your radiator returns drawn as being connected to the upper portion of the tank? My understanding is that for the case of a boiler doing space heating only (no hot water), the returns are the coldest available water and should be connected to the lowest possible point on the tank (to get more condensing and so more efficiency).

Hey Brandon. I'm looking at a re-pipe of a bunch of cast iron baseboard. Local reputable HVAC company advised me to steer clear of pex-al-pex. Seems there was trouble with de-lamination at water temps required of typical cast. Anyone else have any feedback on this point?