If you have any involvement with the world of building science, you may have heard about something called WUFI and wondered what the heck it is. Maybe you’ve heard that it’s a piece of software (several pieces, actually) that does hygrothermal modeling. Well, today’s your lucky day because I recently went through a two-day class on WUFI 1-D with Dr. Achilles Karagiozis†and Mr. Mikael Salonvaara of Owens Corning, and I’ll give you a brief explanation of what it’s all about.

And I’ll give it to you the way we learned about Guy Pearce’s character in the movie Memento; that is, I’ll start with the results and work my way back to the inputs.

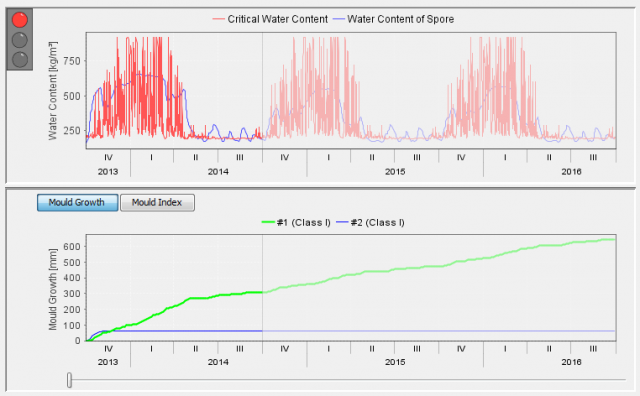

Step 5: WUFI Bio tells you if your assembly will grow mold.

Once you’ve done all the modeling, you can take your results to the add-on program, WUFI Bio, to see if your assembly will be wet enough to grow mold. The graph below shows a material that doesn’t dry out and ends up being a good mold factory. Note the red light at top left.

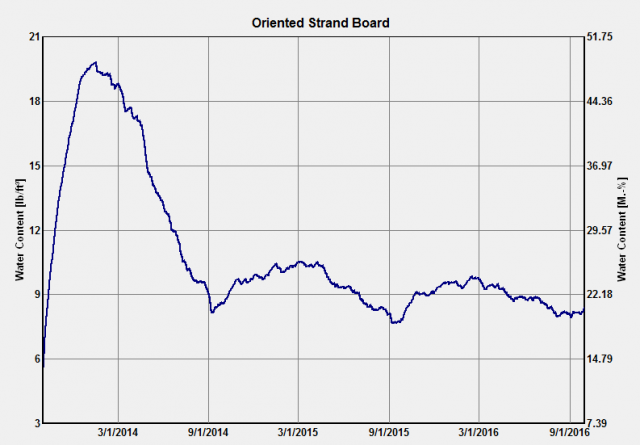

Step 4: WUFI shows how your the water content of the materials over time.

The graph below shows that the OSB sheathing in this wall assembly doesn’t dry sufficiently over the three year period of the simulation. Ideally, you’d like to see it stay below 15-16% (right axis).

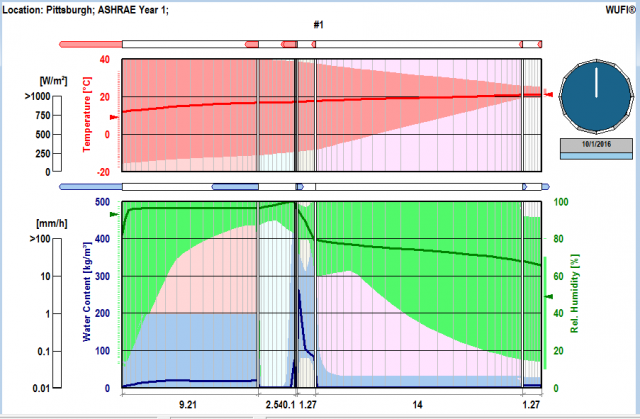

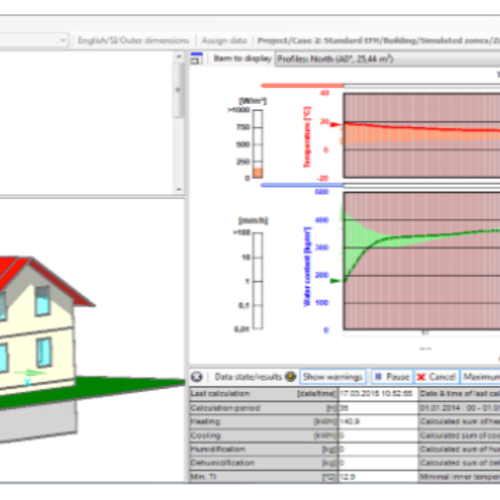

Step 3: Run the simulation and watch what happens in the different layers.

The graph below is one screen shot of the animation you can watch as WUFI goes through all the calculations for moisture and heat flow, hour by hour. The top graph shows the temperature profile, from outdoors on the left to indoors on the right. The red line shows the temperature at that particular hour of the simulation. The pink area shows all the temperatures reached in the various layers, including the minimum and maximum.

The graph below with the green and blue lines and areas shows the moisture analysis. Relative humidity is in green and water content is in blue.

This screenshot of the WUFI analysis animation shows only one point in the hourly simulation. One of the outputs of WUFI is a video showing how the moisture and temperature change over time in the different layers.

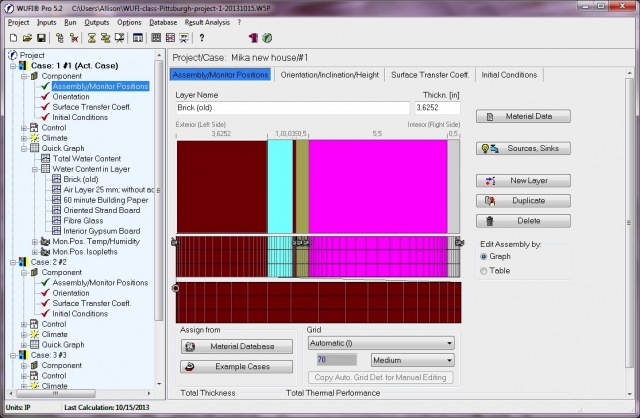

Step 2: Set up your assembly and enter all the inputs.

The screen shot below shows the main screen of WUFI 1-D. The first thing you do is set up the layers of your assembly. The one you see below has brick on the outside, a 1-inch air space, building paper, oriented strand board, fiberglass insulation, and drywall. You choose and adjust the parameters to match the actual materials being used.

You also set a lot of other parameters that control how the simulation will run: orientation, coatings, permeance of paint, climate, wind-driven rain, and initial conditions. The program gives you a lot of power to set everything up with hundreds of inputs. You really have to know what you’re doing to get this right or you could end up modeling a wall that WUFI says will be a disaster even though it’s been working well in the real world for decades. Or you could model a wall, as one architect did, that WUFI says will work fine and then your builder says they won’t build it because it won’t work.

Remember the GIGO principle: Garbage in, garbage out.

Entering the assembly layers and their properties is the most critical part of using WUFI. There are many entries, and it’s easy to mess things up here.

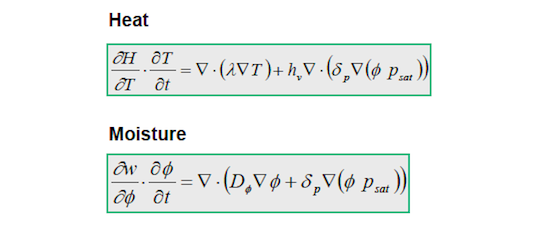

Step 1: Solve the partial differential equations for the flow of heat and moisture.

The equations are shown below. WUFI solves them numerically so you don’t have to.

Prologue

Now let me cover some of the basics. First, you may be wondering what the WUFI acronym stands for, and it is Wärme- Und Feuchtetransport Instationär. According to Google Translate, that’s German for transient heat and moisture transport.

Recall what I said about it being a hygrothermal modeling tool, so it basically looks at the movement—or accumulation—of moisture and heat through an assembly over a period of time. The Fraunhofer Institute in Germany originally created the software, but Oak Ridge National Laboratory (where Dr. Achilles Karagiozis used to work) and Owens Corning (where Achilles now works) are involved in its continued development.

The version of WUFI that I’m discussing here is the one-dimensional WUFI 1-D. Other versions include WUFI 2-D, WUFI Pro, WUFI Passive, and WUFI Bio (mentioned in step 1 above). They have different capabilities and aims but all address the flow and accumulation of moisture and heat. If you’re ready to go a bit deeper in understanding it, I recommend the Fraunfhofer introduction to WUFI page.

That’s it. That’s what WUFI’s all about. I’ll have to come back to this topic because Joe Lstiburek, who likes to argue with everybody, and Achilles Karagiozis have had an ongoing clash over WUFI. Last year at the Passive House conference in Denver, Joe said that if you need to use WUFI, you’ve done something wrong. Achilles opened the two-day class I just took by saying, “No one can do hygrothermal analysis in their heads.” More on that later.

Now, if you want to go even further back, go watch Guy Pearce play Felicia Jollygoodfellow in the movie, The Adventures of Priscilla Queen of the Desert.

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Footnote

†Achilles, by the way, is one of the most interesting and entertaining teachers I’ve had. He’s a dynamo who’s full of information and stories. Although he dashed my hopes with what he said to start the class (see my quote at the end of this article), I loved the class and his teaching style.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

8 Comments

For the most part Joe is right...

You can't do it in your head, but it doesn't take a sophisticated model to tell when you're pushing the line, and there's no real reason to push the line when designing an assembly. Extremely simple arithmetic dew-point calculation models are almost always good enough to tell you when it's close, from a climate-related moisture accumulation point of view, and it's not a rocket-science project to tell if an assembly has the capacity to dry from bulk-water incursions or construction using freshly sawn green timbers. WUFI can tell you how fast & how far the moisture accumulation occurs but that's only critical if you've pushed the line on some really basic stuff.

PhDs

How many PhDs does it take to build a house? Myself, I very much appreciate all the professionals that could be involved in home building. What we need to do is go thru all the PhD work efficiently ONE TIME/ASSEMBLY/ZONE.

Are there dozens of sample WUFI checked home plans available for every zone? If not that should be done via a university with some of the billions in green grant funds.

I will enjoy this topic as it posts.

Aj

WUFI application to modeling existing homes

Was there any talk about WUFI modeling applications as a planning tool for new construction vs. using it to project planned retrofits of existing buildings. I am a HERS Rater and I am not convinced of the value of REMRate on existing home projects. I think REMRate works great on new construction. I have the same reservations about using WUFI to project performance of a deep energy retrofit on an existing home.

Response to Stephen Christensen

Stephen,

I'm glad Allison took the WUFI course, and I'm glad Allison wrote this clear blog introducing the basic concept behind WUFI.

I've been paying attention to WUFI for about a decade, ever since I saw Joe Lstiburek, John Straube, and Achilles Karagiozis running WUFI simulation videos projected on a sheet hung on the wall of Joe's barn. They were watching the moisture graphs rise and fall with the changing seasons, exhibiting the same excitement shown by 8th-grade boys at an R-rated movie.

Lately I reviewed a technical paper by a researcher who ended up deep in the weeds, with contradictory conclusions that were unjustifiable, due to bad inputs on WUFI simulations. If the researchers can't be sure that the results make sense, what hope do builders have?

So, here's the rule: Builders shouldn't use WUFI. Period.

I was on the phone this week with John Straube, discussing some technical questions related to the blog I plan to publish tomorrow, and I started out by exclaiming, "WUFI is driving me crazy. Everyone is misusing these simulations."

John said, "Yes! I agree! It's driving me nuts too."

I said, "Maybe I should write a blog called 'WUFI is driving me crazy.' "

John said, "Yes. You should write it."

Interpretation of Results

Thank your for the brief overview of WUFI. Is there a brief review of how to interpret the results of the simulations? How do I know when too much moisture is too much?

Response to Jeremiah Gammond

Jeremiah,

Q. "Is there a brief review of how to interpret the results of the simulations?"

A. No. WUFI is not a builder's tool or a designer's tool. It is a researcher's tool. Researchers generally say, "Hmm. The result of this WUFI simulation makes sense. It complies with what we already know. However, the result of that WUFI simulation is odd. Maybe we had better do some more validation studies to determine whether the result of the simulation reflects the real world."

Q. "How do I know when too much moisture is too much?"

A. If all you are using is WUFI, you don't. If WUFI raises red flags, it's time for some field studies.

OSB Follies

I suppose OSB could be made waterproof but will the cost meet expectation? Coating with Wax or Polymers, Films, like Metal, Stone etc. are only Lipstick for the building industry's biggest real life PIG.

Someone in the industry must sound the alarm because the real Losers here are the Home Owners who will pay for product failure's. Here's a current article on this site that really make me scratch my head, when will it STOP. http://goo.gl/NXJhsA

Response to George Hawirko

OSB doesn't need to be made waterproof. It just needs to be kept dry and have the ability to dry when it does get wet.

OSB is the dominant material for sheathing homes. Just because you don't like it doesn't make it a bad product or impossible to use. As with most building products, the problems that arise are with installation or misapplication.

Log in or create an account to post a comment.

Sign up Log in