Image Credit: Illustration: Joshua Greisen

Joshua Greisen thinks he’s found an ideal building lot in Yakima, Washington, a city in the south-central part of the state in Climate Zone 5B. Now, can he find a design for a zero-net-energy house to go with it?

Working with a limited budget, but on a south-facing lot ideal for passive solar gain, Greisen is looking for a cost-effective way of reaching his goal. “I’m by no means a rich man,” he writes in a Q&A post at GreenBuildingAdvisor, “and can only afford to do what has a return on investment that will be realized within a decade or so.”

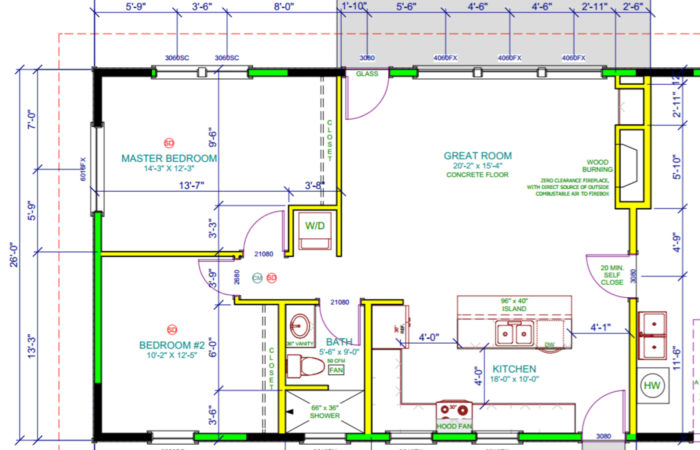

The single-story home he’s planning has a footprint measuring 26 feet by 38 feet, about 990 square feet in all, with two bedrooms, a bathroom, laundry, kitchen, and great room. His plans currently call for 2×6 exterior walls insulated with fiberglass batts and a layer of continuous rigid foam insulation on the exterior — probably 2 inches of extruded polystyrene (XPS).

Other features include triple-pane windows with low-e glass, a heat-recovery ventilator, and an air-to-water heat pump with radiant-floor heating and an air handler to provide summer cooling. He’s aiming for a blower-door test result of 1.5 ach50 or better. He’s also planning on 8-foot-tall doors and 10-foot-high ceilings.

Greisen has a number of questions as he searches for the “sweet spot” for R-values in the ceiling, walls, and slab.

“Code [minimum] in Washington state is R-49 in the ceiling, R-21 in the walls, and R-10 in the slab and stem walls,” he writes. “I have read theR10/R20/R40/R60 rule, but that seems overkill, perhaps, given all the other factors in play that I have noted above.”

His research has uncovered a presentation on R-40 walls showing that 2×6 walls with an exterior layer of XPS…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

8 Comments

blower test

What is the best way to get an impartial / very qualified test done? A referal from ones electrical company? Im just worried that if i call out of the phonebook Im going to get 'upsold' Thanks in advance

Response to Gideon Brontë

Gideon,

If you visit the RESNET and BPI web sites, you should be able to search for certified experts in your region. Call a few of them up and ask about blower door testing.

Most of these experts aren't interested in performing energy upgrades on your house, so I wouldn't worry about conflicts of interest. That said, you can ask always them over the phone: Do you perform energy upgrade work? Will you try to sell me on home improvements?

Wrong climate zone

"Ann also strongly suggested that anyone interested in net-zero-energy homes check in with DOE’s Tour of Zero and in particular Ted Clifton’s Pacific Northwest projects, such as this one."

An odd suggestion.

It's hard for folks outside of the PNW to fathom just how dramatically different the climate is between Clifton's Whidbey Island/Puget Sound location and Yakima, on the eastern slope. It's the difference between very temperate & cloudy zone 4C and sunny dry 5B. The 99% outside design temps on Whidbey Island is about +25F, with a 1% outside design temp in the high 70s (yup, under 80F!)

In the Yakima valley the 99% design temps are in very low positive double digits to high single digits, depending on exact location, and the 1% design temps are north of 90F. The difference in available sunshine is also gia-normous.

Using a Net Zero Whidbey Island house as a template for Net Zero in Yakima would be downright SILLY!

A more appropriate climate, design temp, & sunshine comparison would be Salt Lake City, UT, say Garbett's example on the DOE site:

https://www1.eere.energy.gov/buildings/residential/pdfs/doe_ch_case_studies/2013hiawinner_garbett_100213.pdf

Solar panels aren't all

Solar panels aren't all they're cracked up to be. I would not push this blindly as the cure for a poorly designed building. Thermal efficiency seems to be pointless with all-glass facades. And what is zero net energy really? It's not building an energy-independent system running on its own but rather implementing something else that in theory offsets fossil fuel production annually or whenever because renewables from the grid aren't coming online fast enough to satiate thirst. You get to a point where people start specifying things like aerogel or other things that make the process a technological pursuit and further waste of resources just to aero out the numerical operational values of one building.

Response to Edvin Bishop

Edvin,

I agree that no one should "push solar panels blindly as the cure for a poorly designed building." Neither this article, nor GBA in general, takes that approach to home design.

Nor does this article advocate the use of aerogel.

A net zero house isn't for everyone. But if this design approach is used in a state or region where the local utility offers a favorable net-metering contract, the homeowner can end up with zero (or minimal) energy bills, for an upcharge on the mortgage payment that is less than the energy savings. That can be a very smart approach.

Many thanks!

Another excellent and detailed article.

Much appreciated!

If you're going to kick the aerogel straw man... @ Edvin Bishop

If specifying aerogel to meet an arbitrary Net Zero spec is something to be criticized it's important to find at least ONE case where someone is actually doing that. (If you can actually find that case, I'd love to read about it!)

Net Zero does more than just offset other sources of power, it frees up grid capacity, the flip side of which is that it lowers the capacity requirements of the grid infrastructure. Grid costs are all about peak load capacity.

Twenty minutes into the future behind the meter storage will be cheaper than buying retail from the grid (it already is in parts of Australia), but a lot depends on how the rates are structured. It doesn't take a lot of grid intelligence to make Net Zero houses responsive to the grid, and demand response (even with batteries at 2016 pricing) is a lot cheaper than serving most of those needs with fast ramping peakers, etc. A very low load house with a power system that can be turned into a sub-minute response short term peak generator (or smart load) can and should be remunerated by other ratepayers.

So, sure, 20kw of panel to heat / cool an uninsulated dog house isn't a great idea, but distributed power (whether 100 watts or 100 kilowatts) IS a great idea.

Beginning in 2020 in California the point of Net Zero would be simply to meet code minimum requirements. The grid operators and distribution grid owning utilities can factor the reduced peak capacity requirements into their capital expenditure planning (and they are.)

Cost

I spent many man-hours on cost/benefit on our 2012 DER project.

At the time Roxul CavityRock DD was the best cost/performance for exterior insulation I could find. Based on past quotes 2.5" CavityRock DD (R-10.5) was $0.65/ft2 whereas 2" XPS (R10) was $1.25/ft2.

Since it is breathable no rain gap nor tape is needed, it is naturally fireproof and there are no blowing agents. More details on our project is in a past GBA article:

https://www.greenbuildingadvisor.com/blogs/dept/guest-blogs/wrapping-older-house-rock-wool-insulation

Log in or become a member to post a comment.

Sign up Log in