John Downie and his wife are planning to build a house in Ontario, and instead of choosing a conventional wall system they are considering poured concrete exterior walls that are insulated on the outside.

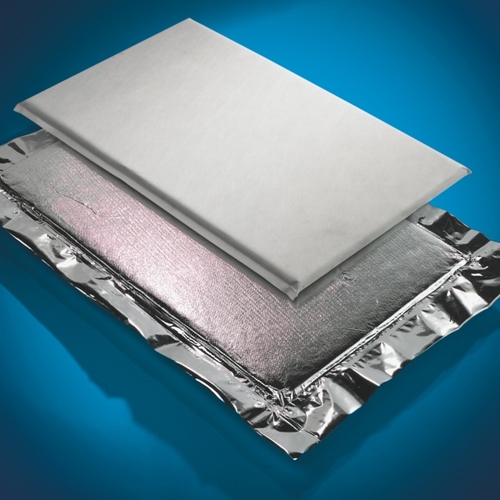

Downie likes the “solidity” of concrete and recalls a comment from former GBA editor Martin Holladay that a poured concrete wall is functionally the same as a wall built with insulating concrete forms (ICFs, pictured above).

Otherwise the house looks fairly straightforward: between 1200 and 1800 sq. ft. over a single story with polished concrete floors, high ceilings, and a gable roof. Heating and cooling would be with a minisplit heat pump.

“I bought a book on ICFs 20 years ago and am still intrigued,” Downie writes in a Q&A post. “I fear, however, that they are the 3D printer of the building world—the wall of the future and always will be…

“To make a short story long, I am wondering if a conventionally poured concrete wall with sufficient external [extruded polystyrene] XPS only would be functional, or would insulation be required on the inside as well.”

Our topic for today’s Q&A Spotlight: Is Downie onto something, or should he look for another way to build his house?

It will work, but…

Although Downie’s proposed wall will be “perfectly functional from an energy efficiency standpoint” without any interior insulation, Brendan Albano writes, it carries an environmental price tag.

“If you are concerned about your environmental impacts in addition to your energy use, it is best to minimize the use of concrete in our project to only the areas where there are no reasonable alternatives,” Albano says. “Concrete is great for foundations, retaining walls, etc., but unless you have very unusual requirements for your home, probably not the necessary for your walls.”

A…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

46 Comments

Autoclaved aerated concrete (AAC) offers another option. It has some R-value, is easy to cut, and available in a variety of blocks and panels. Hempcrete is another system worth looking at (although I have concerns about encapsulating wood framing in the limed-based binder.

Steve,

With either block or AAC I wonder how easy it will be to fasten the foam and cladding? It's something I have have no experience around.

Malcolm,

I understand that wood screws work pretty well with AAC. But it probably would be much easier to put the extra insulation on the interior and simply stucco the exterior.

FWIW. A builder I consulted with who had lots of AAC experience had no concerns about applying cement siding to a house we were considering building. It's has been a few years, but I think he was going to try to reach code on the walls and roof using a prescriptive approach. I was a little concerned about thermal lag and whether the AAC was really going to work in our hot and humid climate.

Re Peter's post, I understand that AAC is really popular in Europe but has a hard time delivering required R-values without supplemental insulation. Faswall type products are considered low-end building materials, at least that's is what I was told by the AAC builder.

We built our home 10 years ago and are going to build our next one this spring and it will be ICF also. We love our home it is all electric and our electric bill is less than $10.00 a day. We get a good rate on insurance, it will with stand 250MPH winds(we have tornadoes in Omaha,Ne.) We have in floor heat and we keep it warmer in the winter and cooler in the summer than most people. The strips are 8" apart for drywall and siding, we have stucco with pigment in it, so we never have to paint. It cost more, but if you are going to live in it for 7 years or more it will pay for it in the long run. ICF, I think is the only way to go. Keith Edmonds,Omaha,Ne

Keith, at $10/day and an electric rate of 10¢/kWh, you are using 36,500 kWh/yr. That's about three times what houses that meet Pretty Good House standards use in cold zone 6. Is your house particularly large, or do you actually pay much less than $10/day?

I can accept the perceived safety aspects of concrete construction, but energy savings are usually much less than ICF fans seem to think.

For those world travelers or those who have lived abroad. One thing becomes quite apparent. Most Americans visiting Europe are frequently surprised that most European houses are not built with stick frame wood. Likewise, most Europeans are surprised when they visit North America and notice that the vast majority of houses are built primarily of stick frame wood. Many reasons for that difference but availability of wood and wood prices in Europe are significantly higher than they are in North America. Plus the tradition of masonry construction in Europe that goes back thousands of years. In Germany one has to go to school and graduate, become a journeyman, and become registered/certified to work with masonry as a builder. Here in the USA, any Joe can swing a hammer and become a residential builder with little to no schooling or experience. (another topic for another day)

Concrete walls have their advantages and disadvantages as was touched on in the above article. Of course, a lot was left out of the article but it wasn't meant to be an exhaustive study or article. If building in tornado prone, wildfire prone, termite infested, and hurricane prone areas. Concrete walls win hands down. Stick frame stands no chance in those types of climate & natural disasters.

As far as "expanding" and future remodeling go. Sure, wood frame walls are easier to knock down and cut out than a concrete wall but it's the size of the lot that usually determines if a home can be expanded, not the wall material. It's pretty rare for city and suburban lots to have enough room to expand width wise on an already built home. The lots are tight and don't allow for this. In rural areas, that's a different story but of all the cities and suburbs I have lived in. I have yet to see one that would allow for space to expand a home.

An alternative to NexCem and Faswall I ran across the other day that looks interesting is Bautex.

https://www.bautexsystems.com/

"The Bautex composite material is simply regular concrete (Portland cement, sand, rock, and water) where the sand and rock have been replaced by expanded polystyrene (EPS)."

They claim a R14 R value.

Bautex is cool, though I'd like to get more than R14 given how thick their blocks are at 10 inches. I'd want to add at least an inch of rigid polyiso or something, either inside or outside, to get better R-values. I guess you can't have it all – masonry walls with a great R-value without them being thick.

Bautex is no longer sold.

Peter, you made a few suggestions here.

"Consider alternative concrete blocks that further reduce cement content, such as NexCem and Faswall."

And then:

"Don’t cheat on the concept of all insulation to the exterior. The insert insulation is just silly given the thermal bridging of webs in any type of block."

Are you saying that if you use one of these systems you recommend additional insulation on the outside?

Nudura one+ blocks do not have a nailing flange on the outside of the block. It is essentially a standard icf block with 4 inches of eps foam glued to the surface. They do offer the xr 35 block which has additional insulation, however it is currently only available in a 8 inch concrete core. Additionally, the insulation is split evenly inside and out instead of leaving as much of the insulation to the outside as possible. Foam inserts, stay away, they are too labour intensive and it’s impossible to make a tight fit. I would rather add rigid insulation over the blocks if required. I would be less concerned with the thermal bridging of a plastic nailing flange than a wood stud in a conventional wall or a large metal fasteners to secure thick rigid insulation, strapping and wall cladding to concrete!

I found this study on ICF blocks interesting:

https://www.icfmag.com/2012/05/temperature-wicking/

Check out the wall system @ Thompsonmoss.com. It has a concrete exterior that uses minimal traditional fiberglass insulation in a 6" stud cavity. Thermal mass keeps required hvac costs down while hidden concrete columns inside exterior stud cavities makes it a beautiful storm shelter. All for the square footage cost of stick framing. I have a 5600 sq ft house with 4.5 ton of heat.

RDMoss,

Your user name suggests you are one of the owners of ThompsonMoss, Inc. Is that correct?

Yes sir. We developed this product to be a better all around product for residential construction.

Thermal mass has little effect in most cases. Insulation and air sealing are much more effective, unless you have large daily temperature swings, a huge amount of mass and/or the mass can be heated (or cooled) passively.

I checked out your website. It looks like your product is making houses that look like log homes but with concrete instead of wood, with cavities cast into the interior side for insulation. The thermal bridging through the webs is significant.

It looks like you're in Tennessee. 4.5 tons of heating for a zone 4 house, even of that size, does not seem particularly low. I don't have experience designing heating systems in that zone but here in zone 6 the houses I design using Pretty Good House levels of insulation, if they were that big, would have a smaller heat load.

>"I have a 5600 sq ft house with 4.5 ton of heat.

--

>"It looks like you're in Tennessee. 4.5 tons of heating for a zone 4 house, even of that size, does not seem particularly low."

That's a ratio 9.6 BTU/hr per square foot of conditioned space, which would be pretty good if the 99% outside design temp were 0F or colder, but a reasonably designed tight code-minimum stick built house with wood siding could meet or beat that at typical TN design temps of 15F - 20F

If it's a 4.5 standard (not cold climate) heat pump, and it covers the load during Polar Vortex disturbance cold snaps it's probably noticeably better than code.

Log houses made sense when people arrived on a new continent covered in abundant timber, with nothing more than an axe and handsaw. To recreate them out of concrete defies logic.

I appreciate the aesthetic--or rather, I understand why people would appreciate the aesthetic--and plenty of other house details are mimicking something else. For example, fiberglass columns that are supposed to look like wood columns that were supposed to look like stone columns that were originally made to look like refined versions of wood columns. But to build a house using such high-carbon materials when there is no tangible benefit does not make sense to me.

I'm disappointed in how lazy or conservative the experts are on this issue. The construction industry has a strange culture of laziness and "good enough" that I don't fully understand. They always want to do the minimum possible that satisfies code or standards, never want to hit a level of excellence or build something out of the ordinary.

It's also strange how these experts keep talking about cost. That's the home buyer's concern, not theirs. Builders and engineers should only care about cost as a constraint established by the buyer – they're the ones paying it. To pre-emptively harp on cost when it's obvious that the buyer is willing to shoulder some added costs is just weird.

The challenge of how to attach siding to the exterior insulation seems pretty modest. I'm sure they can figure out several ways. How do they attach siding to ICFs? Seems like it would be a similar solution since you'd be attaching to foam in both cases.

Bluesolar,

The overwhelming majority of residential construction is done speculatively, and that means it is cost-driven. As houses are commodities that all exist in the same market, it also means custom-builds are subject to the same cost constraints.

Building without regard to cost leads to a a couple of outcomes: As a client, your custom build isn't worth what you paid to build it. As a builder, you can't compete unless you limit yourself to the boutique market of wealthy clients who don't care about expense. If all we are discussing here is what's possible, divorced from any practical or cost constraints, then the answer is pretty much anything, and there is no no way of choosing what to do beyond asking the owner what they would prefer.

Most builders are conservative because a) they want to eat. And b) innovation can lead to unexpected consequences - usually envelope failure. This site is about high performance buildings. If excellence outside of that criteria is what you are after, there are lots of beautifully designed concrete houses on Dezeen or Archdaily.

You dismiss the problems that we are discussing by saying "they can figure it out" . Well the "they" are the experts you deride who are flagging them as problems in the first place. How would you attach the cladding and foam to a block wall?

Hi Malcolm. I would use screws to attach cladding to a block wall, going right through the foam (this may or may not involve screwing through the foam, or I might just punch through the foam and screw into the concrete only – I'm sure the builder, architect, and engineer would have something to say about it). Or I would look at however they attach cladding to foam ICF blocks and use that method to attach the cladding to the foam insulation, or to the foam and concrete both.

My criticism of the experts in this article doesn't mean that I wouldn't rely on experts on things like how to attach cladding to a house. Also, I think this is ultimately going to be a trivial challenge. We put a man on the moon 50 years ago, and I'm flabbergasted that anyone would think attaching cladding to a concrete house with foam insulation on the outside is beyond the abilities of construction professionals or even of a high school shop class given two weeks to furnish multiple solutions. And again, ICFs probably already give us some answers.

Your point on costs sounds reasonable. I think I'd want a process that looked at various innovations or, more likely, extra solid build quality, and would want to be presented with the costs for various scenarios. For example, I might want a basement, which are extremely rare in Arizona. I'd want a poured concrete basement, not block, ideally precast. Now with basements there are tables and guidelines for the concrete basement wall's thickness, based on soil type, height of wall, and other factors. If the tables specified an 8-inch wall, I'd want 10 inches. I like conservative and fail-safe engineering, especially in construction.

And I'd want more robust water sealing of the basement walls than what you see in this picture from The Wall Company in Phoenix (basement specialists). I'd want something more solid than a worker manually spraying a coat on site, something like a solid PVC or HDPE barrier, sealed well enough to not trap water between it and the concrete. I'd probably be willing to pay an extra ten grand for a better basement, maybe more.

BlueSolar,

If you are looking to do a basement in the desert SW, shoot me an email, I've done research on the topic. [email protected]

Also, I just discovered that exterior wall insulation is common in Europe: https://en.wikipedia.org/wiki/External_wall_insulation

It looks like they've solved the problem of attaching cladding to or through foam insulation.

And I just discovered that applying insulation to exteriors is something that occasionally happens in commercial construction in the US. It turns out that they have all kinds of ways of attaching siding to or through exterior insulation, specially designed fasteners and so forth. So John Downie might benefit from talking to some commercial builders or architects with relevant experience. One random example of fasteners they use: https://www.rodenhouse-inc.com/continuous-insulation

It is done all the time on larger commercial structures. I've specified it myself. That's not the context we are talking about. It's like asking why we don't use steel structures in houses, include curtain-walls, or provide underground parking garages. The OP was asking whether it made sense to build a concrete house in Ontario. So far, beyond preference, there is been no compelling evidence brought up to support doing so.

Architects don't preemptively dismiss options, or try and substitute "good enough" alternatives. They are paid for their experience, not their ability to Google. If you ask me why you shouldn't use concrete I would tell you the pro and cons - including the problems of trying to get commercial trades to have anything to do with working on an individual house build.

It's also worth considering the this discussion is occurring on a Green Building site, so it's hardly surprising that the comments take that into account.

Fair points Malcolm. I don't think concrete is ideal, but I respect the preference and especially the broader preference for solid masonry construction. In Tucson we have lots of old adobe homes, and concrete seems like a more modern version (sans the insulating value of adobe).

I'm puzzled by your comment on steel structures though – aren't steel framed homes popular? Not as popular as wood frame, sure, but I thought they were definitely a thing. In the comments below we have Mark from SIC Systems, who makes steel frame with EPS foam. And there's ThermaSteel who brilliantly turned the steel studs sideways to eliminate thermal bridging, and fill the wall with EPS. I'd love a steel framed home, or something like this bolted moment frame design: https://blueskybuildingsystems.com/offerings

“[Deleted]”

Oh I'm all for sensitivity to costs. My point was that engineers and architects shouldn't preemptively nix or dismiss ideas because they think it would cost more than the "good enough" solutions they seem to prefer. I think they should just pass on all the cost info to the home buyer and let the buyer decide what they're willing to pay for.

As far as "name calling", I'm not sure what that means exactly. Is it just criticizing people, or using adjectives or other words to describe people? I'm a social psychologist and I'll think about it some more. A general injunction against name calling strikes me as a playground ethics, and I'm not sure that I'd want adults to be bound by playground ethics, or that I'd even want children to be bound by such an injunction if it just means criticism. I think we need criticism, and that criticizing people is a great way to get them to think about their behavior.

Here's a question - why do you need concrete at all? Other than a footing, the use of concrete in residential foundations or above grade walls is no longer a necessity for construction, it's really a case of "we've always done it that way" isn't it? Concrete has a high environmental footprint, its expensive, it requires specialized equipment (pump trucks) and trades, you have to use rebar to give it the required strength, it cracks and leaks and has an insulating value close to R-Zero. Every concrete foundation or wall requires another layer or system to separate the occupants from the concrete (frost walls, interior insulation, moisture sealing products) and/or separate the concrete from the effects of environment (external insulation, tar damproofing, the walls of ICF forms).

Now I'll provide disclosure here, I am likely biased in this opinion as I do manufacture an alternative to concrete, but let's be clear. There are better alternatives and new technology available every day for better buildings, and new home builders need to start changing from the way it's always been done because the same is just not good enough anymore. We don't need to find a slightly better concrete to build the same way, we need to find a better product and build differently. Start by checking out http://www.sic-sys.com and then continue to look online for other newer, better ways to build. I hope the conversation changes to whats new, and look forward to the comments to come!

Hi Mark. Your company's method looks awesome! It's close to a perfect wall, with the structure and insulation occupying the same space, or being the same material.

I'm also sympathetic to John Downie's desire for a concrete house. I think concrete is just another masonry wall option, and concrete homes are common in some parts of the world. I think it serves as an alternative to a wood-framed house in most people's minds, just like other masonry options (concrete block, CMUs, clay, adobe, Bautex, etc.) Some people really want a solid-feeling masonry home, and I see Downie's interest in concrete in that vein.

When you ask why someone "needs" a concrete home, or say that it's not a "necessity", I think you're rubbing up against a different way of thinking. The construction industry seems to think in terms of doing the minimum, or doing what's necessary. A lot of people outside the industry don't think that way, and would not think of home construction as something to be driven strictly by what's "needed". Some people just want something excellent, and when it comes to homes they want something solid and enduring, so masonry fits the bill, including concrete. The need to add an extra layer of insulation is a minor issue for concrete homes, and no different from lots of home construction methods. I think the key is that people like the solidity and toughness of concrete.

Back to SIC Systems, some questions. How are you hitting those R-values given the thermal bridging of the steel studs? How would you contrast your approach to ThermaSteel's REVPANELs? The difference I see is that they flipped the studs sideways to eliminate thermal bridging – their studs don't go through the foam. What gauge steel do you use for the studs? And isn't the foam flammable? I thought it was a fire hazard or something, so I've been thinking about using mineral wool batts instead, even though they're only R-4 per inch or so. Why EPS instead of XPS or polyiso?

Thanks for your comments. Your expansion of the "needs" and "necessity" aspect I was describing is a more rounded presentation of what I was trying to get across, that the construction industry at least in my area does focus on doing the minimum. That often does get presented to customers as they way it should be done, so kudo's to those who look past the norm for something excellent.

For the queries on our SIC Systems, some brief answers are as follows:

- Our high R-Values are possible because the system has NO thermal bridging. The steel studs are only partway into the wall insulation, leaving 2 inches to as much as 6 inches of unbroken exterior insulation thickness on the outside face

- We are similar to the Themasteel panels in components (steel and EOS) but different in an engineered approach to every wall section. Our product is engineered to meet the structure needs of the building, you don't have to design the building around the specifications of the system.

- Steel studs vary based on engineering for each home, but most projects require only 18 or 20 gauge galvanized studs

- Construction EPS has a fire retardant that prevents it from self burning, an exterior fire source is needed at high temperatures to burn it, it doesn't burn by itself.

- EPS has stable insulation values, XPS and Poly-Iso insulation values decrease over time as the blowing gases in those products leach out and are replaced by air or moisture. EPS does not use the environmentally harmful gases that blown foams do either. EPS is also more cost effective and easy to cut and shape to required sections and panels.

I appreciate your interest and information, contact me through the email and phone on my website if I can be helpful in providing any additional information. Thanks - Have a Great Day! http://www.sic-sys.com

t

That looks great Mark. I wonder, does it accomplish anything to fill the stud C-channel cavities with EPS? The steel is thermally conductive, so filling the C-channel cavity would seem to be as useful as filling it to prevent electric current from traversing the stud – that wouldn't work. It also prevents homeowners from using things like toggle bolts to mount heavy objects to the wall. Those things need the empty cavity to flip open. Mollies might not work either. I wonder how people mount heavy objects – do screws bite into the EPS?

The foam in and around the studs actually provides structural assistance to the studs, the compressive and tensile strength of the foam is a benefit to the load capacity, vertically and laterally, of the assembly

Heavy objects would be mounted to the wall studs, easily done and capable of meaningful weight carrying ability. Hanging in between the studs there are a few spiral anchors that could be used to support in the drywall or such, not impossible but choice would depend on the situation.

Mark, your system looks interesting, and I'm all for finding alternative ways to build durable, efficient homes and other buildings. The combined embodied carbon of foam (even relatively benign EPS) plus steel (which releases about a pound of CO2 for every pound of material) is still pretty high, though.

Another concern with your system is the focus on thermal bridging. Where you have steel studs 2" from the outside edge in a 6" panel, or 1/3 of the distance from exterior to interior, the temperature inside the foam will be 1/3 of the difference between exterior and interior. So when it's 10°F outside and 70° inside, the outside edge of the steel will be 30°. Because steel is an efficient conductor of heat, the inside edge of the steel will also be about 30°. When you have more exterior foam, so the outside face of the steel is halfway between exterior and interior, the steel will be roughly halfway between exterior and interior temperatures.

In contrast, while framing with solid wood creates thermal bridges, because wood is still an insulator (about R-1.2/in), the inside face of the wood will always be close to room temperature.

Michael, thanks for the comments.

To the embodied carbon, the recycle content of steel in the studs and recycling of the studs at end of life and the ability to recycle EPS easily at end of life will provide some significant pro's to the life cycle carbon, unlike may other materials including wood that require disposing of at end of life. The new focus on Embodied Carbon, while important, seems currently to not be defined down to a standard evaluation protocol that compares building materials on the same timeline process, and scale. Too often statistics can be made to prove anything if they are selectively defined and presented. Thats a whole other topic, I'm not disagreeing with you on the importance of embodied carbon, I just think the whole building material industry is currently more concerned with finding a way to statistically show their materials are "better" instead of really doing equal and meaningful comparisons.

I do however have t0 disagree with your thermal bridging comments on our system. Quite simply, it doesn't work that way. You are surmising that a conductive piece of steel that is by your definition at 30 degrees on one face, (which it is not because it is insulated from the cooler outside temperature by at east R9 value of insulation) and at 70 degrees on the other face (being only separated from the inside building temperature by a R=0.45 thickness of drywall, will revert to the 30 degree temperature and cause a cold bridge. As it is more insulated from the cold than the warm, by a factor of 18, its tendency is to the inside temperature not the outside. Compared this to wood, where a 2x6 at R1/2 per inch with 1/2" of plywood on the exterior is providing only R3.25 separation form the exterior while our wall system provides at least R9 between the outer aligned face of the stud within the wall section and the actual outside temperature. In terms of thermal transfer from one face to the other therefore, our wall is almost 3x more insulated than traditional wood frame construction even before you start in on the inefficiency of the cavities in a wood wall. Looking at potential mold and rot issues that wood can have when moisture and condensation issues come up, I would use the steel-stud and EPS wall system every time.

Mark, if the indoor and outdoor temperatures are constant (which of course they never are, but if they were) and the insulation is homogenous (not foam + fiberglass or some other mix) and ignoring the slight additional R-value from drywall, cladding, air films etc., no matter what the indoor temperature and outdoor temperature are, the temperature inside the insulation will follow a straight line from the outdoor temperature to the indoor temperature. 30% of the way through the wall, the temperature will be 30% of the difference between indoor and outdoor temperatures. At the center of the wall, the temperature will be halfway between the indoor and outdoor temperatures. It doesn't matter what the materials are or what their R-values are--it's the same for an R-10 wall and an R-100 wall; the only difference is how quickly the heat moves through the wall. So other factors aside, in my example the outside face of the steel will be 30°F. This is building science 101 level information, not particularly complicated. It gets somewhat trickier when you look at the wall system in three dimensions and you include additional materials but it won't change the end result significantly.

I agree that your wall will perform better than a code-minimum 2x6 assembly. However, framing lumber, plywood and osb are not R-0.5 per inch, as you claim--they are R-1.2 to R-1.3 per inch. A 5 1/2" 2x4 performs at about R-6.7. Including drywall and sheathing the wall will be about R-7.3 at the studs.

Here's my stab at this:

If the SIC walls have 2" of EPS exterior to the metal studs, they could probably be considered to have a bit more than that R-value (R-8?) at each stud location due to the high conductivity of metal and the way it bends around to present a larger face perpendicular to the path of heat flow. (Approximately. If someone ran the calculation, perhaps it would be less conductive than I'm imaging due to the thin gauge?).

The largest change in temperature will occur across the higher resistance to heat flow, so the delta T will be greatest over the 2" of foam. Sort of analogous to voltage drop across resistors in series.

https://celsiainc.com/heat-sink-blog/fundamentals-of-thermal-resistance/

Thinking too hard about the temperature at various points within the wall might just confuse (at least me), since it's not an example of a homogeneous circuit, but ultimately the high rate of transfer through the steel is the weak point. The steel will be room temp at the interior, but the interior heat will have a highly conducive path to within 2" of the exterior, at which point the R-value of that 2" EPS is what stands between the conductive steel face and the outside environment.

In conductive terms, one might be-able to almost visualize no studs present at all in the assembly with the vacancy of the studs being air pockets void of insulation, open to the interior (simplification).

Whether or not this constitutes a thermal bridge or no thermal bridge is semantics.

Have a look at Superiorwalls.com AG product. The thin high strength concrete IS the outside finish, with foam on the interior, including the concrete insulated studs, Cavity space allows for additional interior insulation with wiring holes precast into studs to fasten gypsum interior panels to.. Panels are factory built and erected onsite, and bolted together.

A quick Google search brings up some pretty bad issues.

https://superior-walls.pissedconsumer.com/walls-separating-and-failing-201808011318235.html

Like I stated before. There is no "one way" to build or one material that is superior to another material. Building materials are location dependent, climate dependent, and most importantly, what one is trying to achieve with their build (energy efficiency, storm resistance, wildfire resistance, etc. If you lived or live in Oklahoma, Kansas, or anywhere within the violent tornado belt region, where EF3 or stronger tornadoes happen. You are thankful when those tornado sirens go off that you have an above ground concrete storm shelter or below ground storm shelter (the latter is not always practical due to soil and water table issues). Concrete has its place in building and always will. Above ground concrete tornado shelters have saved countless lives. All materials have their strengths and weaknesses. Use what is needed in your particular region to build an energy efficient but resilient home.

I keep getting emails about more posts to this query, but when I click the "view comment" button there are no comments shown after #24, JAn1 2020

It's probably referring to replies to earlier comments up above. There were several new ones today. You have to scroll up to see them.

Quick answer to M Tylers implied question:

“ Downie might consider why there aren’t a lot of concrete houses located around him. “When a common material or technology fails to find a place in house construction, there is usually some reason for that,”

The reasons for that is simply: unwillingness to learn and improve, and resistance to change.

That is so in any industry! I’m a software engineer/consultant and most of the shops i’m called in to help the programming style is 20 or more years old!

Sliding windows can never be/remain as tight as swinging ones (european style) - but we still have them. Top-loader washing machines were stopped being used in europe more than 50 years ago. We still have them! They built excellent electric cars in the late 90 - yet still most cars use combustion engines…

The list goes on…

As somebody else (i think bluesolar) said: “Experts” recommend same-old-same-old - it is good enough and a know quantity; no risk of being sued, no need to extend effort to learning something new…

My motto: listen to what experts have to say, but ask why. Then google and double check. And use your common sense. Don’t trust what an expert says blindly - especially since (as somebody else also already pointed out) in the US anybody swinging a hammer long enough claims to be an expert, so you never know if the expert really has expertise …

Thomas,

I'd buy that if concrete hadn't been the established material of choice for multi-family buildings for a century, used in high-end modernist houses in North America for the same amount of time, and wasn't presently used extensively in most of the rest of the world for housing.

It's not lack of experience or inertia that holds back concrete, it's that it compares unfavourably with wood frame construction on a continent with abundant timber supplies, in terms of cost, ease of construction, adaptability and environmental impact. Anyone who prefers to can build a concrete house. The expertise is there. All I suggested is that, much like when you see an alluring swimming hole with lots of people on the beach but none in the water, it's a good idea to find out why before jumping in. .

Wood is the perfect building material for cold, cloudy, sea-level regions where you don't face the threat of wood-destroying insects, wildfires, or tornadoes, and the thermal mass of masonry walls doesn't help very much because there aren't large daily temperature swings from the sun or high altitude. All you're left with to sell masonry are "the feeling of solidity" and maybe resilience in a flood (as long as you don't built an interior studwall with sheetrock!) which gets counterbalanced by various drawbacks. So logically northeastern builders logically see no real reason to admire and promote European masonry products the way they admire and promote European windows--which are similarly better than their American counterparts.

Living in the sun belt region of the USA, we face large daily temperature fluctuation from both sun and high altitude. We have wood destroying insects. We have flash floods. We have intense summertime heat that can be greatly reduced by mass and ground-coupling, and insulation traps heat already in the building as much as it resists the entry of new heat. So I can tell you that the European masonry walling products are better than stucco over a stick frame in the same way that those European windows are better than American single-hungs and sliders. It's just that the European windows are better in a way that matters to northeastern builders, while the European masonry walls are not. And it's fairly well known that northeasterners are over-represented here at GBA.

Digging deeper, we should ask: why are northeasterners over-represented on GBA? I think an awkward truth is that green building is something that uniquely appeals to them, and not others. The northeastern part of the USA has always been the most progressive, the most environmentally conscious, the most concerned about human rights, egalitarian justice, and so on. It's been this way since the founding; I think it's just baked into the country's cultural DNA. So I'm not real surprised that there are a lot of Massachusetts and Vermont builders who fret over the emissions from every pound of concrete and seek to improve the quality of building, while most builders in the rest of the country don't (they certainly don't in New Mexico, where I live). It's just a cultural difference.

It also presents a way forward: those of us who want to promote the use of masonry materials should not target northeastern builders, and should not advertise potential "green" or "eco" qualities, as northeasterners are the ones who care most about that stuff. Rather, we should go to Texas and Oklahoma and tell the builders, "you know, if you build your houses with masonry, you can advertise to buyers that they won't be destroyed by the next tornado, they won't be locked in a deadly battle with Formosan termites for the rest of their lives, they won't have the experience of running the furnace in the morning and the air conditioner in the afternoon, and their homeowner's insurance rates will be really low."

Log in or become a member to post a comment.

Sign up Log in