Image Credit: Schluter Systems

A warm bathroom floor is a something to look forward to on a chilly winter morning, and C.L. is poking around for ideas on the best way of accomplishing that.

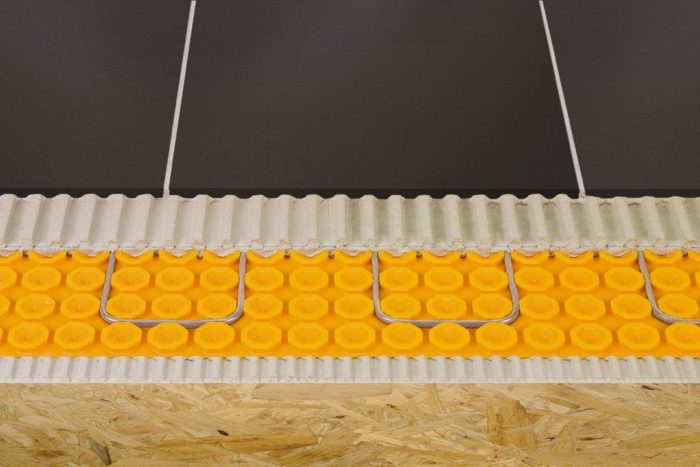

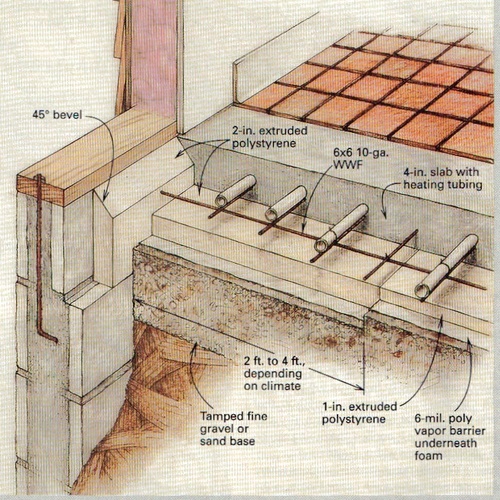

One option is installing a grid of electric cables beneath the finish floor in tandem with a polyethylene underlayment manufactured by Schluter Systems called Ditra. These installations are often topped with ceramic tile, which is impervious to water damage and readily transmits heat from the buried cables.

But C.L. has another idea.

“In regards to finish flooring over the heated floor in the non-shower part of the bath, cork looks like an interesting product,” C.L. says in a recent Q&A post. “Although cork is sometimes discussed as an insulator, the [manufacturers] of solid cork flooring propose it as an ideal finish floor for a heated floor; supposedly it heats fast.

“Does this sound reasonable, or is this just marketing hype?”

That’s the topic for this Q&A Spotlight.

First, how efficient is electric heat?

C.L. begins his post with a question on whether there’s a recognized metric for measuring the efficiency of electrically heated bathroom floors. Actually, there is, points out GBA Editor Martin Holladay.

“Yes,” he writes. “The metric is called ‘efficiency.’ It describes the conversion of electrical energy into heat energy. All electric-resistance floors have the same efficiency, namely 100%.”

This is technically true of all electric resistance heat, whether it’s in the floor or not. But Jon R suggests that definition doesn’t go far enough.

“A reasonable definition of efficiency would involve useful work,” he says, “so I’d exclude any heat lost to the underside of the floor. This efficiency will be less than 100% and cork will lower it (as compared to something more thermally conductive…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

9 Comments

Efficiency aside, how much energy?

We opted out of a heated bathroom floor during our remodel. I couldn't find any data on how many kWh/year we could expect it to consume, not even a ballpark. Anyone know?

Eric

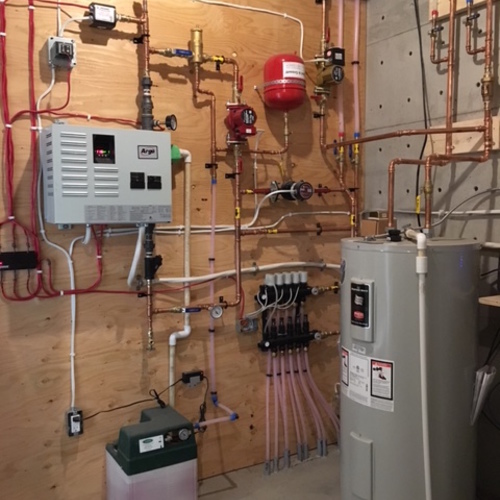

If the floor heat is only used during the period when you are supplying heat to the rest of the house, wouldn't the only additional expense be the difference between the efficiency of the two heat sources? If the rest of the house was supplied by similar resistance heat,would there be any additional cost at all?

Product Warranties

Relying on product warranties can bring a lot of grief. They generally cover manufacturer's defects and problems that occur when the product is installed according to the supplied instructions. But what they warranty is usually just the product itself. So you may get the damaged or defective material replaced, but the labour to do so, the work necessary to integrate the material into the rest of the house, and the cost of making good surrounding or supporting materials isn't generally covered.

Response to Eric Sandeen

Eric,

Dana did the math for you -- the answer is 11.4 watts per square foot in the example he gave.

For an annual estimate, you would simply multiply 11.4 watts times the square footage of floor heat, times the number of hours per year that your family wants to run it, divided by 1,000 to get kWh.

That's only it's maximum output @ Martin, Eric

Assuming there is at least some thermostat in the controls it would still have a duty cycle. Even when in use, and would not be running the 11.4 watts per square foot continuously, but would be cycling on/off based on the room (or floor) whether it had reached the thermostat's setpoint.

Michael's estimate of 2kwh/per hour would mean it's running a constant 2000 watts (=6824 BTU/hr), which is a HUGE amount of heat, several times the heat load of most bathrooms even at the 99% outside design temperature. The heat load of the main bathroom at my house is about 1100 BTU/hr when it's -10F outdoors, +70F indoors, and that's before subtracting out the heat emitted by the lights, or the shower/bath. OK, so I have a small bathroom, but even if the design heat load were 3-4x bigger, 2000 watts would be extreme overkill, and it would take (2000/11.4=) 175 square feet of electric radiant floor to emit that much heat.

Note the arithmetic error in my quoted forum post creates overly optimistic expectations):

"...it can deliver 41/1.33 = 39 BTU/hr per square foot..."

Uhh... make that ~31 BTU/hr per square foot, not 39, which is ~9.1 BTU/hr per square foot, not 11.4, so it would really take about 220 square feet of radiant floor to deliver 2000 watts of heat into the room. The per square foot estimates that followed also have to be scaled back, since they're based on the original arithmetic error (eg, With only 85% of the heat going up and 15% losses to elsewhere would be 0.85 x 31= ~26 BTU/hr per square foot.)

Whatever the real numbers for C.L.s bathroom are, even if it's heated solely by the electric floor and on continuously under thermostatic control it's not likely to hit 500 kwh /year unless it's a gia-normous bathroom with a large amount of window area (which isn't very common for bathrooms) adding to the heat loss numbers

Response to Dana Dorsett

Dana,

Thanks for your corrections and improved math. Very helpful.

240V

A friend put in the Schluter system a while back and loves it. Just wishes he had upgraded his electrical line powering the heated floor to 240V.

Thanks

Thanks for the detailed answers on expected energy use. ~500kWh/ year isn't too bad I guess; I was hung up on electric resistance heat as a source compared to our efficient boiler... in retrospect it might have been a good idea. I don't think I'm going to revisit this decision with my wife... :)

But it really WON'T be using 500 kwh/year @ Eric Sandeen

I know it's only my hacked version of 'merican, but parsing it correctly helps:

"...even if it's heated solely by the electric floor and on continuously under thermostatic control it's not likely to hit 500 kwh /year unless it's a gia-normous bathroom with a large amount of window area..."

The key phrase being "...it's not likely to hit 500kwh /year..."

The napkin math on this for MY house looks like this:

At an indoor to outdoor temperature difference of 70F the heat load of my sub-code circa 1923 bathroom is about 1000 BTU/hr.

1000 BTU/hr =293 watts or 0.293kw

So in a 24 hour day at an indoor to outdoor temperature difference that big it that's (0.293 x 24=) 7 kwh.

That's also about 65 heating degree days (base 65F), but for the sake of making the math easy call it 70 HDD.

So the power use per HDD would be about (7kwh/70 HDD=) 0.1 kwh / HDD.

If my bathroom were located a 5000 HDD climate it might hit (5000 x 0.1=) 500 kwh/year, if the radiant floor was the ONLY heat source, was on ALL the time, the lights were never on, and nobody ever entered or bathed there, and the door was always closed. (As it happens I'm in a ~7000 HDD climate, not that it really matters.)

In a real bathroom in a house with central heating there are other heat sources- from the main heating system, hot water use, lights, and occupants, all of which would offset the power used by the floor. Thus the power used by the floor is "... not likely to hit 500kwh /year..." even if it might hit or even exceed that in a worst-case scenario. If the radiant floor is only on when the bathroom is occupied it will be less than 100 kwh/year, maybe even less than 50 kwh/yr even if the heat loss of your bathroom is twice mine.

Log in or become a member to post a comment.

Sign up Log in