Despite decades of efforts to promote recycling, the amount of plastic waste generated in the U.S. continues to climb while total recycling rates have declined to single digits, the environmental watchdog Greenpeace says in a new report.

The assessment, Circular Claims Fall Flat Again, is a followup to a 2020 Greenpeace USA survey, and it found little has changed: Plastic recycling basically doesn’t work, with only 5% to 6% of the total output in the U.S. recycled each year.

Lower costs for producing virgin plastic resins, increasingly complex plastic goods that thwart recycling, and the toxicity of recycled plastics all contribute to the difficulty of turning recycled plastic into new products, particularly food-grade packaging, the report says.

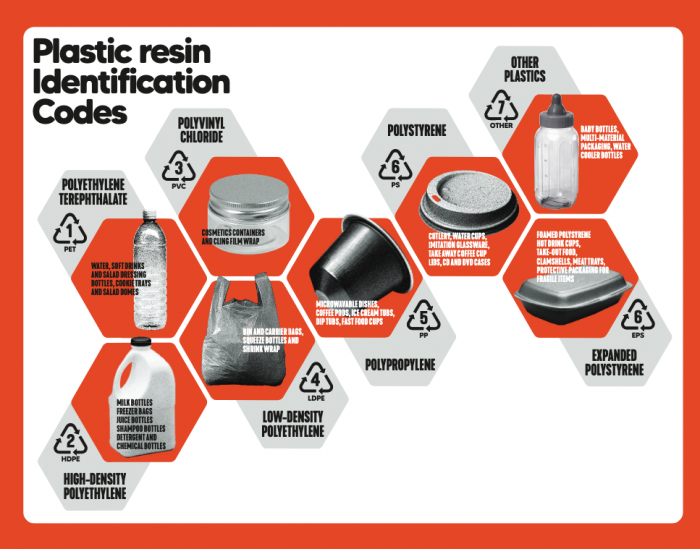

Only two of seven common types of plastic—PET #1 and HDPE #2 plastic bottles and jugs—are widely accepted at the country’s 370 material recovery facilities (MRFs), Greenpeace said. Reprocessing capacity remains below thresholds set by the Ellen MacArthur Foundation’s New Plastics Economy, a benchmark report advocating a circular economy.

“The high recycling rates of post-consumer paper, cardboard, and metals in the U.S. prove that recycling can be an effective way to reclaim valuable natural material resources,” Greenpeace said. “Plastic recycling in particular has failed because the thousands of types of synthetic plastic materials produced are fundamentally not recyclable.”

Because of the risk of toxicity in recycled plastics, post-consumer household plastic waste is not being used in new food-grade products neither globally nor in the U.S. and probably never will be, Greenpeace said.

The recycling industry sharply disagreed with the findings, and claimed that Greenpeace skewed the data to make recycling look less successful than it actually is. (Separately, representatives from more than 150 countries gathered in South America at the end of November to begin negotiating a treaty that would reduce plastic waste, as the Washington Post reports. And a recently introduced bill in Congress would set targets for reducing plastic production. There’s more about that here from Grist.)

Greenpeace said society is at a decision point on plastic waste. “Instead of continuing on this false path, companies in the U.S. and around the world must urgently phase out single-use plastics by replacing their packaging and reuse and refill systems and offering packaging-free products,” the report said.

An environmental advocacy group called The Last Beach Cleanup was equally critical in a report published earlier this year. It accused the plastics and recycling industries of waging “a decades-long misinformation campaign to perpetuate the myth that plastic is recyclable.” Not only is the recycling rate abysmally low, the group said, it would be even lower if it included the plastic that is collected for recycling but ultimately is burned instead.

Recycling rates have declined since 2018 as China and other countries have stopped accepting plastic waste from the U.S. Total plastic waste increased to more than 35 million tons in 2018 (the last year covered in reports on municipal waste from the Environmental Protection Agency) while the recycling rate has remained below 10%.

“The U.S. plastic recycling rate peaked at a dismal 9.5% (including exports) and is now in an irreversible decline to eventual insignificance,” the Last Beach Cleanup said.

The group advocated a ban on single-use plastics, the creation of more water refill stations to eliminate wasteful packaging, and programs that increased the availability of reusable food and beverage containers.

Recycling industry disagrees

While environmental advocates accused the plastic industry of intentionally misleading the public about recycling, the industry said it’s the other way around.

“Americans overwhelmingly support recycling,” the Association of Plastic Recyclers said in a statement earlier this fall, “but too often their enthusiasm is met with discouraging and usually misleading data points.”

Low recycling rates cited by the EPA and others include containers, packaging, and durable goods intended to last for many years as well as plastics never intended for recycling, such as plastic garbage bags. However, the types of plastics that most Americans use—such as water and soda bottles, yogurt tubs and the like—do get recycled at a much higher rate, according to the trade group.

The most recent information available for PET and HDPE bottles dates from 2020 and shows a recycling rate of 28%, the association said. Polypropylene (PP) bottles are recycled at the rate of 17% and other 8% of other PP rigid containers are recycled.

In an upbeat assessment of the recycling industry, the group said that plastic recycling is responsible for more than 200,000 jobs in the U.S. and succeeded in processing nearly 5 billion pounds of post-consumer plastics into new products.

Both the recycling industry and its critics agree on a couple of points. One is that the boom in shale gas production and drilling has helped drive down the cost of virgin plastics, making recycled products that much less attractive. Another is that plastic packaging has become more complicated, making recycling and processing more difficult.

The way out of the plastic mess, the group said, is to recycle more plastic, not less.

“Today, the market demand for recycled plastic material is outpacing the supply of post-consumer plastic that is being collected and processed,” it said. “As a result, it is now imperative to grow the supply of post-consumer plastic material. The U.S. will need to double or triple collection of most plastic resin types to keep up with corporate sustainability commitments and the projected demand for products made from 25% or 50% [post consumer plastic].”

Recycling rates for PET and HDPE bottles could exceed 40% with existing processing facilities if more plastic were recycled.

Recyclers also acknowledged that the U.S. needs to develop “robust” public policies for better product and packaging design, simplify recycling, and encourage the demand for recycled content.

“It is unfortunate that Greenpeace and other critics of plastics are focused on attacking the one solution to the plastic packaging sustainability problem that works: recycling,” Kara Pochiro, APR’s vice president of communications and public affairs, said in an email.

She continued, “There will always be plastic packaging, so it is essential that it is sustainable. Recycling is a vital vehicle to do this. If we want to be serious about tackling the plastic problem, we must be serious about strengthening recycling. Misleading reports like this, which can discourage consumers from recycling, are not only destructive to our communities, but also to the environment and the economy.”

Visiting a local recycler

Among the country’s 370 recycling plants is ecomaine, a nonprofit owned by 20 area communities and housed in a 30,000-sq.-ft. facility in Portland, Maine. It serves a total of 73 municipal members and is one of two such plants in the state.

What started in 1978 as an operation to bale trash is now a sophisticated handler of paper, metal, cardboard, and plastic capable of sorting 150 tons of mixed recycling per day. It’s a single-sort facility, meaning households throw all recyclables into a single bin—cardboard, paper, glass, metal, and plastic. Plastics #1 through #7 make up only 2% of the total.

On a recent tour of the plant, Matt Grondin, ecomaine’s director of communications and public affairs, explained the process by which mountains of unsorted household are sorted, packaged, and ultimately readied for shipment elsewhere (see the Gallery for more photos).

Initially scooped up by bucket loaders and hoisted onto a conveyor, the refuse climbs into the upper reaches of the plant where it is directed to a variety of sorting lines and devices. There are machines that crush glass (no market for that these days), others that spear slabs of cardboard, and even one that chemically analyzes plastic and culls out PET containers with a puff of air. Where automated devices aren’t effective, ecomaine employees stand next to conveyors as streams of material rush by, plucking out different types of material by hand. What goes in one door as truckloads of mixed refuse comes out the back door as neatly baled blocks of cardboard, paper, and plastic.

Ecomaine sells all of the plastic it handles, with #2 HDPE (high density polyethylene) commanding the highest per ton rates ($1437 per ton in fiscal 2021), followed by #1 PET ($182 per ton), and finally #3-7 mixed plastic, which sold for $57 per ton last year. That last category is the hardest to unload, Grondin says, but ecomaine sells it nonetheless. Because it’s comprised of mixed resins, it goes into products where appearance and exacting performance specs aren’t important.

Ecomaine’s success also is a clue to why plastic recycling rates may be so low elsewhere. Grondin estimates the cost of building a plant like this could range to $25 million, which helps explain why even relatively desirable plastics like #2 HDPE gathered in smaller communities go to a landfill or are burned in a waste-to-energy plant.

“There are 115 cities and towns, mostly in central/eastern Maine, that contract with a regional organization called the Municipal Review Committee,” Grondin said in an email. “Their facility has been closed down for almost three years, and all materials, trash, and recyclables alike, have either gone to PERC, a waste-to-energy plant, or a landfill.”

Plant operators hope to reopen in the spring, he added, but when they do only some of the plastic will be recycled for new products while the rest will be turned into plastic briquettes to be used as fuel.

“Other towns might handle their own separated recyclables, and market those themselves or through the Maine Resource Recovery Association, which acts like a broker,” he said. “Often, these towns might take just #2 plastics, sometimes #1 and #2, but often not #3-#7, which will end up in a landfill or waste-to-energy plant.”

Some communities may have no access to plastic recycling at all. The problem is widespread. Greenpeace estimates that only 60% of the U.S. population has access to municipal collection services for PET #1 bottles and jugs and HDPE #2 bottles and jugs. That number falls precipitously with other types of plastic, down to just 5% for plastic cups, 3% for plastic trays, and 0% for plastic cutlery and straws. The EPA recently announced $100 million in grants aimed at improving local recycling options.

Construction waste is another story

If plants like ecomaine can find ready markets for even the least desirable types of plastic, how does it do with construction plastic waste—various kinds of plastic plumbing, plastic decking off-cuts, vinyl siding scraps, and housewrap remnants? Plastic building materials typically last for decades, but when buildings are razed or renovated, the amount of waste can be significant. And in new construction, scraps and off-cuts are unavoidable.

If the material is sorted at the job site, can it be recycled?

Not at recycling facilities like ecomaine. Grondin says the plant is not permitted to accept construction and demolition debris either at the recycling plant or its sister waste-to-energy facility across the street. That kind of plastic waste goes to a landfill where it is used to cover up raw trash to control litter and ward off pests.

This type of plastic waste accounts for a large portion of non-recyclable plastics that Greenpeace uses in its calculation of total plastic waste, Grondin said.

In a recent post at GBA, Fernando Pages Ruiz described a post-consumer recycling program for vinyl siding developed by manufacturer Kaycan. Storm-damaged siding was ground into a granular material used to make the substrate for new siding. The program was successful, according to the company, and the Vinyl Siding Institute lists a number of manufacturers who participate in recycling efforts.

But how widespread the practice, and how other types of plastic waste can be recycled, isn’t clear.

Calls to the Solid Waste Association of North America and the Institute for Scrap Recycling Industries were not returned.

Scott Gibson is a contributing writer at GBA and Fine Homebuilding magazine.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

One Comment

In case folks haven't already seen this, the PBS series Frontline did an episode covering the origin of plastic recycling. The recycling effort was pushed by the plastic industry, given the pushback they were getting from people throwing plastic packaging in the trash. Recycling programs was intended more to make people feel better about consuming plastic packaging, rather than a realistic strategy to replace virgin feedstocks.

PLASTIC WARS Season 2020: Episode 14

https://www.pbs.org/wgbh/frontline/documentary/plastic-wars/

Log in or create an account to post a comment.

Sign up Log in