Doug Mancosh, founder of Fiberon Composite Decking, has developed a building material that could help redefine standards for recycled content and performance. The new siding and trim products from RISE Building Products represent a leap in synthetic materials science, driven by a mission to repurpose scrap materials previously destined for a landfill.

Recognizing the value of a siding material made with 94% recycled content, the building materials giant Saint Gobain—a proponent of the circular economy—entered into a joint venture last year with RISE Building Products. They introduced RISE siding and trim at this year’s International Builders Show, where I met Ben Skoog, an early pioneer in the product’s development. He gave me some additional background.

“RISE siding began with the ambition to transform our approach to building materials,” said Skoog, whose experience in composite sidings contributed to developing technology that produces a hard, durable product from soft, post-consumer recycled carpet fibers and fiberglass. With legislation in California and forthcoming laws in New York mandating the recycling of carpet fibers—a notoriously difficult-to-decompose material—RISE was conceived to make use of this raw material stream.

Fiberglass and carpet fibers

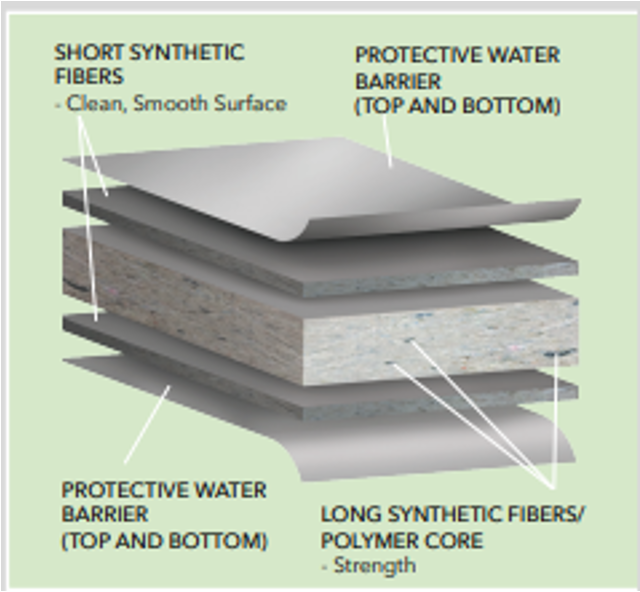

RISE products are a combination of recycled fiberglass and carpet fibers, such as polyesters and nylons, pressed into boards for a weather-resistant substrate. “The pressing process is the key that transforms loose fibers into a dense and durable siding product,” Skoog said, “turning high-quality interior plastics into a robust, all-weather, [all-climates] product.”

Approximately 56% of the material in RISE siding is post-consumer carpet fiber diverted from the landfill. Recyclers separate the fibers from the carpet backing (often used as asphalt filler), and bundle the fibers into bales that are sold to RISE. Roughly 30% of the mix is polyester and nylon that come from the type of carpet found in automobile foot wells and trunk liners; manufacturers send RISE post-industrial waste i.e., carpet remnants from products made for the auto industry.

Approximately 11% of the RISE composite is surplus fiberglass from the production of batt-and-roll insulation. Fiberglass fibers are also sourced from the scrap created in the production of wind turbine blades and old blades recycled at the end of their service life.

The remaining 4% of the product consists of binders like formaldehyde-free polymeric MDI (pMDI), an adhesive used in the manufacturing of several exterior-grade materials including fiber cement, structural insulated panels, and exterior insulation and finish systems (aka synthetic stucco). Thermal adhesives hold the fibers together as they are compressed in a 12:1 ratio, meaning 1-in.-thick trim was 12-in. thick before being rolled into the press and sandwiched between sheets of resin-impregnated overlays. The composite fiber mats are pressed into large sheets and then milled into siding profiles.

Fiberglass from wind turbines

The long fiberglass rotor blades that create the torque needed to produce wind-generated electricity have a huge disposal problem. They don’t decompose, so when damaged or retired, the old blades are buried in the field, like soldiers fallen in battle. “By repurposing fiberglass from retired wind turbines, we’re not only utilizing high-quality materials that would otherwise be wasted but also addressing a significant materials challenge,” said Skoog. The fiberglass helps stiffen the siding and reduce the material’s thermal coefficient, decreasing the amount of heat transfer in the final installed product.

Using recycled fiberglass also reduces manufacturing costs. “Buying virgin nylon, polyester, and high-quality fiberglass would not be economically [sound]. Our sustainable sourcing model allows us to compete with engineered wood and fiber cement siding,” Skoog added.

Available but limited

RISE siding’s introduction is a milestone for recycled content in the construction industry, offering an alternative to traditional siding materials that is durable, sustainable, and comes in two popular profiles—clapboard and board-and-batten.

“Our goal is to establish a new standard for building materials in terms of performance and environmental responsibility,” Skoog said. For now, you may not find RISE siding at home-improvement stores, but the company provides a list of suppliers in 14 states that carry RISE products.

_______________________________________________________________________

Fernando Pagés Ruiz is a builder and an ICC-certified residential building inspector active in code development. Images courtesy of manufacturer.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

6 Comments

It seems preferable to vinyl siding in terms of material inputs. In either case though once installed it seems like they both would be shedding lots of microplastics. It would be great if they studied that aspect of this product.

graygreen,

"In either case though once installed it seems like they both would be shedding lots of microplastics."

Do they? I thought these types of claddings didn't release micro-plastics until they break down after they are discarded? In terms of overall micro-plastic pollution sources I've never seen vinyl listed:

- Synthetic textiles

- Tires

- City dust

- Road markings

- Marine coatings

- Personal care products

Thank you.

Great idea; I hope it works! Having a market for recycling turbine blades would eliminate a common argument against turbines. I'm leery of any new synthetic siding product, as there have been so many failures of other new products, and I still prefer bio-based materials when they will work, but most people seem to prefer synthetics so this could be a really good solution.

What about the new rice hull and PVC product ACRE fom Modern Mill. Is it any good? Anyone with experience with it?

Jsbrunt (hi John!), I haven't used it myself but this is a good overview: https://www.greenbuildingadvisor.com/article/rice-husk-siding-and-trim-board. In the comments there, I wrote, "It sounds to me like when you're stuck in a position where you have to use a synthetic, rot-resistant material, this rice hull product has advantages over the other products."

Log in or create an account to post a comment.

Sign up Log in