I am working on a series of foundation assembly diagrams for some single-family new construction projects in Southern California. We are developing both monolithic slab-on-grade details and crawl space details, but we expect to use the SOG detail more often since that is a much more cost-effective solution in our area. Our relatively forgiving (for now!) climate makes it difficult to convince clients to voluntarily exceed the minimum insulation requirements per Title 24 and code, but nevertheless we always encourage them to do so (and may soon insist on it).

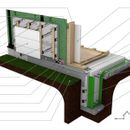

I am hoping for some ‘crowd-sourced’ feedback on these two assemblies, which are based on a variety of recommendations from sources such as GBA, BSC, Fine Homebuilding, JLC, Matt Risinger videos, etc. I’ll spare you all the specifications but broadly: the cladding will be James Hardie fiber cement with a rainscreen (CoraVent at the top and bottom and 1×3 battens); the vapor barriers would be StegoCrawl or StegoHome (with an option to upgrade to Pango for better termite protection); the sheathing will be Huber’s Zip; we will recommend 2″ exterior rigid insulation (see specification question below); the foundation waterproofing will likely be Poly-Wall’s Home Stretch perhaps with Arroyo drainage board (see below). For the SOG we would have an additional (10mil?) vapor barrier between the slab and 2×4 sleepers (on the flat) with ‘floating’ AdvanTech subfloors and engineered wood floors above. Sill plate to concrete sealing would be handled with Contega HF acoustic sealant above and below a foam seal (both above and below a termite shield) and then Prosoco R-Guard joint and seam filler between the face of the Zip and the horizontal flange of the termite shield.

We recognize the ripped wood sill we show between wall and foundation rigid insulation slightly short-circuits the thermal break, but we want the detail to be adaptable if a client approves the wall rigid but wants to omit the foundation rigid. In particular, on the slab-on-grade detail I am hoping for some feedback in terms of the following:

01) Confirmation that no perforated drain tile is required for a monolithic slab-on-grade that is above surrounding grade (8″ higher)?

02) Recommendations on the best dampproofing specification for the outside face of the slab edge, presumably down to the bottom of the footing/grade beam.

03) Would a dimpled drainage mat (not yet depicted) be warranted in addition to the dampproofing or is that superfluous since there is no basement or crawl space? If it should be incorporated, would it go between the rigid (reduced to 1 1/2″ thick to stay coplanar with the above-slab rigid in the wall) or outside of the rigid?

04) Most of the GBA details show the vapor barrier only extending partially up the outside face of the footing/grade beam. Would it be better to take this all the way above grade since it is concealed behind the rigid?

05) Would you recommend a different rigid product for the slab edge than what we will use for the wall rigid? (ie. EPS or XPS instead of Foil-Faced Poly-Iso?)

06) What is everyone’s consensus on the best-looking method for protecting the rigid between grade and top of slab? Is sheet metal extending to 6″ below grade the best bet? If so, stainless steel or something else that would take paint better? I love the concept of EnergyEdge but not a huge fan of the aesthetics at the corners.

07) The 2″ rigid insulation in the wall (above slab) could be either foil-faced Energy Shield PolyIso by Atlas (depicted) OR Rockwool Comfortboard, OR EPS. Any strong feelings on which of these would offer the best value/performance?

08) Since a termite shield will necessarily project beyond the rigid insulation, would you suggest the Prosoco R-Guard joint and seam filler be installed both above and below the horizontal flange of the termite shield for air sealing?

Thank you in advance for any feedback you are willing to share!

Replies