Can I use canned spray foam in rafter bays in unvented roof assembly?

michaelbluejay

| Posted in Green Building Techniques on

SUMMARY: Is canned spray foam superior to cut-and-cobble polyiso in rafter bays in CZ-2?

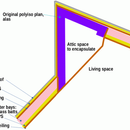

DETAILS: In a finished attic room I have a poorly-insulated attic space between two skylight wells. I’d already cut polyiso panels to cut-and-cobble into the rafter bays when another member pointed out in another thread that this isn’t advised because of the condensation risk, and I then found Martin’s cut-and-cobble articles on the subject.

So now I’m wondering, would canned spray foam be a better solution than cut-and-cobbled polyiso? The space in question is small (4 rafter bays at 22.5″ wide x 3.5′ rafter length x 5.5″ rafters). That’s 12 cubic feet. On a web forum someone tested the volume of a can of Great Stuff and said it was 0.27 cubic feet, so that would be 44 cans, maybe less for the black can “Big Gaps” flavor. At $4.74/can that would be $209, close to what I paid for the polyiso.

The space is unvented and can’t easily be vented. Neither end abuts a gable wall, and I’m not comfortable trying to install wall vents from the outside due to the height and slope of the roof, and hiring out the work isn’t in the budget, and even if I got the vents installed, they’d be in the same plane so I’m not sure how well they’d work.

I think the condensation / rot risk is slightly mitigated by the 3/8″ EPS on top of the roof decking, and the warmer climate (CZ-2), but it seems the risk is still there.

I know the proper method is pro spray foam, which is not in the budget right now. For now, I need a way to be able to insulate this attic space without breaking the bank and without inviting condensation to cause my structure to collapse into a pile of whimpering rubble.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Search and download construction details

Replies

I have no comment about the suitability of the spray foam compound for that purpose, I don't know what it's made of and how it differs from the two-part foams that are normally used. The two-part foams come out to about 2.5 pounds per cubic foot; if Great Stuff produces .27 cubic feet from a 12 ounce can that comes out to about 3 pounds per cubic foot which seems reasonable.

The difficulty with using can spray foam that way is that it doesn't stick well to vertical surfaces. Specifically, if it gets too thick it sticks to itself better than it sticks to the surface and it forms a ball and falls off. You can avoid that by putting on multiple thin layers and letting the foam harden between layers.

You might do a little better by going up a step on the price/performance ladder and getting "pro" foam with a spray gun.

There is a device you can buy on Amazon called a FoamBeak that is designed to spread foam into thin layer. I've never used it but I always found it intriguing. The reviews are mixed.

You can buy smallish 2-part foam kits and they work well. A popular size is 200 board feet but that's a lot more than you need. Even with them you have to apply the foam in layers of 2"

I would not try using regular canned foam for this, since you’ll have a very hard time getting an even layer free of voids that cures properly. Great stuff (and others like it) can’t really be applied in a continuous layer very well, and if they’re applied over around 1” thick or so, you can start having issues with the interior not curing properly. This doesn’t get you the same level of mess that improperly cured 2 part spray foam can make, but it does severely hinder the insulation any ability of the material. One part canned foam is what is know as “moisture” or “water” cure foam, meaning it needs to scavenge moisture from its surroundings to cure. With thick layers, this doesn’t work well. You can sometimes improve things by misting some water onto the surface before foaming, but that can sometimes mess up the adhesion of the foam leaving gaps.

Two part spray foam is much better, but your choices are a tiny 12 board foot kit (that is around $60-70 and tends to underperform in terms of how much foam you get), then a 200 board foot kit that is around $300-350 or so. There is a sort of in between option, using some new one part canned foam variants made for this type of application, such as the Kraken Bond brand spray foam you can get through Amazon. I’ve used this stuff before, and while it’s not as good as two part spray foam, it’s much, much better than great stuff for use on a large area. It’s still difficult to get an even layer, so you end up needing to use more foam than you’d expect, but it seems to be able to cure properly in thicker layers. Note that you need to buy their special gun for this stuff, since the plastic tips they provide don’t fit on the usual great stuff gun.

Bill

Okay, this is very helpful, thank you.