Do I need underlayment for a Japanese-style shed roof with metal shingles?

I’m building a small Japanese timber framed garden shed DIY project here in the Willamette Valley of Oregon. The shed has an unusual (in the West) roof structure. I’d like some help thinking through whether I need an underlayment and if so what kind on my (planned) plank decking below interlocking terne metal roof panels (Quadro panels from finemetalrooftech.com).

The shed will have no conditioned space and the gable ends will be open lattices so there should be plenty of air movement below the ceiling. It will be more like a pavilion than an enclosed structure.

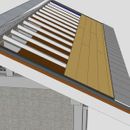

The sketch shows the roof, about 1.5 squares, 5/12 pitch, Port Orford cedar rafters on 12 inch centers. On top of the rafters will lie approximately 1×6 ship lapped 15 mm thick ceiling boards. That will be the finished ceiling. Surrounding the ceiling boards is a 36 mm thick joined perimeter frame. On top of that perimeter frame is a second 36 mm thick perimeter frame which overlaps it to create a drip edge and surrounds a 21 mm deck of 1×6 planks that will be spaced 3 mm apart to allow for their seasonal movement. Furring strips placed vertically over the rafters will also support the decking.

The manufacturer of the metal panels specifies a HT ice/water shield WRB over 5/8″ to 3/4″ CDX. I intend to use plank decking. Some WRB makers say plank decking is OK but want it to be layed tight with no gaps. That seems like a bad idea to me since the planks will move seasonally. But I can see that the seasonal movement might tear a peel and stick membrane. I can switch to 5/8″ CDX decking if necessary but I’d rather not since I already have the planking. I have the eave and rake flashing from the manufacturer of the roof panels.

So here are a few questions about my design:

Do I need a HT underlayment?

Do I need any underlayment? If so does it have to be peel and stick?

Could I use 30# felt instead?

What underlayment would I expect to last the longest under a 50 year plus roof?

Should I be concerned about the structure having a partially enclosed space between the lapped ceiling boards and the spaced plank decking?

Any other suggestions to improve how this roof works?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Bumping this up.

In general, I'm having trouble finding good information about building green structures that aren't residences and aren't conditioned spaces. Am I overthinking, or underthinking this?

girino,

- There is no downside to using an underlayment, and it will help protect the decking from condensation or leaks.

- If you are installing an underlayment under metal, it should be one rated for HT. That precludes 30# felt, but doesn't mean you need a self-adhered one.

- Any of the HT underlayments will probably outlast your shed. The problem will be finding somewhere that sells small amounts so you don't end up with a big roll and nowhere to use it.

Many thanks, Malcolm. The roof is about 1.5 squares so I can use most of a 2 square roll.

I'm designing the shed to last a 100 years or more with minimal maintenance. Timber framed, lime plastered walls with rain screen, terne metal roof with wide overhangs to keep the walls dry. I'll be really disappointed if it doesn't make it that long ;>) . But if it doesn't, someone will be able repurpose or recycle almost the whole thing.