Fine tuning the blower motor settings on a ducted Heat Pump (Mitsubishi)

I am looking at the specs for the Mitsubishi ducted heat pump units.

The unit is a 30000 btu exterior single zone hyper heat compressor (suz-Ka30NAHZ) with an internal air handler, designed for ductwork.

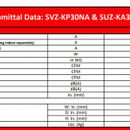

As you can see the blower motor uses 244 watts. The air handler has 3 settings 613cfm, 744cfm, or 875cfm. The last one is 0.8WG and the lowest setting is 0.3WG.

The indoor unit gets its power from the outdoor unit, there is a 240v wire running between the two units.

So my questions are:

1) what are the advantages and disadvantages of setting up the unit on the highest static pressure setting, 0.8WG as opposed to the lowest?

2) Does the HPSF of the system change when the static pressure setting is changed? Is there a way for me to measure it?

3) Since the blower motor running 24/7 at 244 watts would be a large amount of power, and there is no point to waste energy just moving air in circles in my house, what are some strategies to optimize how much the fan actually runs?

The thermostat for this unit has options for “auto return” and also for “energy saving” where you can set the unit to use just 90% of the usual energy, down to 50%. I don’t really understand what these settings do yet.

Besides that, I am thinking that the thermostat location is critical… you do want the thermostat in area where the heating of the building reaches it in a reasonable time frame.

Currently the blower stays off much of the early evening as we lower the thermostat a bit at night but then it comes on at 1am and stays on much of the night making the air a bit dry for my liking by the morning.

Any tips on how to fine tune the thermostat settings and static pressure setting of these units for maximum efficiency would be appreciated.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I think you may be confusing a few of the statistics.

The air handler has 3 speeds (l/m/h) or 613cfm, 744cfm, or 875cfm.

It also has 3 settings for static pressure (which is resistance in the ductwork). The variable speed air handler will vary the speed of the motor to ensure that you get as close to 613cfm/744cfm/875cfm, no matter what the environment.

The static pressure configuration is one input into how the motor will vary to ensure that you always get close to 613cfm/744cfm/875cfm.

If you want the fan to shut off when not needed, you need an external thermostat/control so the temperature of the space can be detected.