Improving attic ventilation past heel blocking

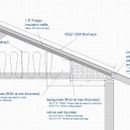

I’m about to replace the asphalt shingle roof on my house (climate zone 5; Spokane WA) and need to improve the attic ventilation. The presence of soffit air-intake vents and insulation baffles in the attic (first attached image) lulled me into thinking intake ventilation was adequate. Unfortunately, there is blocking at the truss heels that almost entirely blocks intake airflow.

Hoping to get advice between what I see as the two best options, or suggestions on a third:

1. Install shingle-over intake vents part-way up the roof. Use spray foam in the attic to fill the space downhill of those vents (from roof deck to attic floor). Will the humidity from a bathroom/shower along this outside wall create excessive moisture in the spray foam or roof decking? (roof decking will have code mandated ice-and-water shield at least 24″ in from the outside wall)

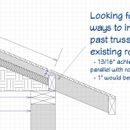

2. Cut tops off of blocking to expand air gap to 3/4″ or 1″ in order to make the soffit ventilation useful (notional diagram attached). I’m leaning this way since I already plan to air-seal and re-insulate the attic this year, and will have access to the blocking from the outside when I re-soffit and re-side the house next year (to include adding hurricane straps). Any thoughts on whether cutting the tops on the blocking is advisable or feasible; any ideas on how to cut them lower?

Thanks!

-Mark

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Mark,

I favor option #2 as well.

Hopefully your framer was a bit lazy and didn't nail the sheathing through to the blocks. That will make things a lot easier. If there is a slight gap between them and the sheathing above, as your section shows, you can push a reciprocating blade through and then cut a U- shaped opening as deep as you want. If the block is tight, you will need to drill a pilot hole for the blade. Leave a few inches of meat at each end so the blocks are still effective.

Malcom,

Fortunately, there aren’t any nails from the roof deck into the blocking that I’ve come across.

And a huge thanks for the sanity check on approach! I know this doesn’t guarantee smooth sailing, but it really helps to know I’m not committing to a completely foolish approach.

-Mark

The sheathing should have been nailed to those blocks. They are supposed to be there to transfer sheer from the roof diaphragm supposedly.

I'm not sure if they are only needed on sheer walls, in high wind or seismic areas or everywhere?

Apparently they are a highly debated and argued about issue.

I was going to post a question about the best way to comply with having them at the same time as creating the recommended 1.5-2" vent channel under the roof sheathing for a ventilated roof assembly.

I've seen holes drilled in them but the holes are always shown too low to be in the vent channel.

I was considering cutting out like a 1" deep by 8" long section in the middle of each one and install Cora vent strips or leave them open. That way the panel can be nailed hopefully 12"? On center and comply with the engineers wishes that these blocks be installed.

sayn3ver,

As you say, the blocking is used in high seismic and windy areas to join the wall and roof diaphragms, but they also sometimes included, much like joist blocking, to stop the rafters or trusses from turning over. In those circumstances they are often not nailed to the sheathing above.

+1 for trimming down that blocking to open up a gap. The other option would be to cut some holes in it with a hole saw, to open it up similar to what support beams in aircraft look like.

Note that you mention code mandates 24" of ice and water shield in your area. That's not much, it's a good idea to go "two widths" up, so about twice that 24" amount (roll out one strip at the eave, then roll out another strip above that for "two widths" up the roof). This stuff is cheap insurance against water problems in your exterior walls due to ice dams and the like.

Bill

Bill,

I thought about adding holes one the middle of the blocking, but decided against it since that would further reduce the already meager amount of insulation that can fit above the top-plate of the wall. It would be a different story if the house had raised heel trusses everywhere.

Thanks for the advice on the ice-and-water shield. I’ll definitely ask the roofing company to take it a little higher, if they didn’t already plan to. A second course would extend it past the lower edge of a planned solar array, which might reduce the chance of rain/snow shedding off the array and backing up under the shingles.

Cheers!

-Mark