Improving the thermal performance of steel windows

We are installing a 15’x7′ wall of custom steel windows in New York. Unfortunately, our steel fabricator, who is extremely nice but clearly out of his comfort zone with this project, already built out the frames and is not able to create a modern thermal break. Instead, he has used 1.5″ steel tubing for the entire perimeter. We will be able to install large panes of double glazed glass, which should have excellent insulating properties. However, we are concerned that the amount of “unbroken” steel in the framing will lead to significant thermal bridging, condensation, and sweating. Since the metal framing has already been constructed and is a “sunk cost,” we are wondering if there are any strategies to improve the thermal performance? (installing insulation in the tubing? Plastic shims between the glazing and frame? Exterior insulation and sheathing?)

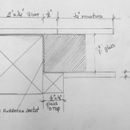

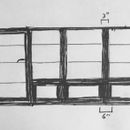

We’ve attached a few pictures and sketches to help demonstrate what we’re talking about (please forgive my poor drawing abilities)

Anyway, this is well beyond our area of expertise and so we would greatly appreciate any advice on how to make a less than ideal situation somewhat better.

Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Major bummer. I think you should have dealt with an experienced window fabricator, not a welder. I don't foresee a happy result.

It might be best to just pay the bill to the welder and say, lesson learned -- and then contact a window manufacturer. Other home builders have suffered more expensive lessons. Time to move on.

-- Martin Holladay

Go talk to a commercial curtain-wall fabricator. maybe they can put something to salvage the situation.

Thanks Martin and Malcolm. Unfortunately, we are stuck with the 1.5" steel tube frames and will need to figure out how to make the best of the situation. Right now, we are leaning toward adding insulation and sheathing on the outside, which should help somewhat with the heat transfer and condensation issues (see attached sketch). If we go that route, we still need to think through the details at the operable door and window. Fortunately, we are using very large panes of double glazing (7' x3') and the 1/4" steel muntins are simulated and don't actually separate the glass. Hopefully, that should improve the thermal performance of the overall units. That said, any suggestions on possible solutions that would still let us use the 1.5" tubing for most of the project would be very helpful. We'll certainly talk with some folks who do curtain walls to see if they have any suggestions.

Thanks again!

I know from ongoing personal experience that the most difficult thing to change is one's mind, but here goes. The physics of the arrangement will follow their own immutable laws, regardless of our preferences. Window design and even more so, operable window design, has engaged the minds and time of knowledgeable engineers for thousands of hours and hundreds of trials and errors. Like so many other things in life, the complexity of window design and fabrication puts it beyond our ability to think our way through to a successful first iteration. Here are some options:

1. Decide that beauty is worth pain and proceed with the cage knowing that you will experience condensation and air infiltration. Just surround the window with materials which are impervious to moisture and stay a comfortable distance away during cold weather. People have lived with poor windows for our entire history.

2. Think that you'll be able to salvage the sunk cost. The result will be similar, but with additional disappointment.

3. Wisely heed Martin's advice (based on decades of experience) and use the money you will waste on salvage toward an effective solution. Look at the price of the steel as a ransom paid to free you and your loved ones from years of irritation. Money paid to improve lives is not wasted.

Hey, I know it's not my money and the poor option may be the only choice. Best wishes.

When I read your comment -- "our steel fabricator is extremely nice" -- I was reminded of my father.

My father had a long-term relationship with an auto mechanic -- the kind of mechanic that Click & Clack always used to joke about. When my father walked in the door, this mechanic said to himself, "I know how to make my next boat payment!"

Every time my father stopped by, the mechanic discovered a new $600 problem. Whenever anyone in our family suggested that my father should take the car to another mechanic for a second opinion, my father would answer, "But this guy is really nice."

-- Martin Holladay

When you say "New York" do you mean the state or the city? I took it as the city, and I think the "rules" are sometimes different there. A few thoughts:

*We have an apartment in a landmarked building in midtown Manhattan. The building has steel framed single pane windows that are about 90 years old now. They leak like a sieve as they don't close tightly, have no gaskets etc. But they have lasted many, many decades. Trying to think why, I think that their longevity is in part due to their original good construction, quality of the steel, dynamics with the building / drying capability, how they were installed in the wall etc. OK, maybe they were coated with paint that had additives you can't use anymore too. The point is that they were extremely well built for the day. And you know what, if you replaced them with new super tight windows, you would probably cause other problems with "air quality" in the apartments.

*If you stay with the steel frame, perhaps a lesson you might take from the paragraph above is to balance insulating them with air movement so moisture isn't trapped and they rust. Might be a situation where one type of insulation is better than another.

*Is the frame going to be powdercoated? Can you clean and prime/paint all areas? Will you be able to mount them without scratching the paint down to bare metal? I am dealing with this issue right now on an exterior steel stairway we are having fabricated; we know there are some internal tube areas that we can't coat. How do you make sure rust stains don't weep at the wrong spot.

*In New York City you always have to think about whether someone is going to come along and upset your apple cart. Is your curtain wall at ground level where a bad actor might be inclined to try to break in? If so, steel may have an advantage over other more complex assemblies.

*You have a contractor that you seem to like, your project is underway, and it appears he is doing quality (albeit not exactly optimum) work. Man alive, in NYC that is awesome. Don't let him go!

Maybe you can call a firm such as WG&M (http://walshglassandmetal.com/our-services/) and ask them to assess the work to-date. The staff there way see a way to make the current frame work (or not).

I am in the process of purchasing aluminum clad thermally broken windows. They are basically wood windows with the aluminum attached using a thermally broken locking screw. If I were you and I had to use the steel frame that has already been fabricated, then I would see if the glazer can design the windows so that the steel is treated as cladding that is thermally broken from the glazing.

I think this would have been a great project for one of the European window manufacturers. They can make anything, customize it to the millimeter and as long as one of the dimensions is under 10', it can be as long as a container. Maybe you can reposition that sunk cost and turn that steel into a big picture frame, hang it inside and fill it with a collage of artwork?

Thanks for all of the feedback (and encouragement!). As for the fabricator, he is actually the exact opposite of the mechanic Martin mentioned (Click and Click are among my all-time heroes). No matter what we ask or additional work we include, the price never goes up. He just wants to do a good job.

The project is on the top floor of an old factory in NYC, so the frame should be safe from foot traffic. It will be galvanized and powder-coated and presumably, shouldn't get scratched during the install. That said, we are still very concerned about the risk of condensation on the interior of the framing.

I'm glad the fabricator is honest, and making no attempt to raise his rates. I never meant to imply that he was anything but honest. I told the story about my father's mechanic for only one reason: to remind everyone that when evaluating technical issues, "nice" is irrelevant. (But of course -- nice is nice.)

-- Martin Holladay