Cut-and-Cobble with Polyiso and Spray Foam to Insulate a Vented Crawlspace

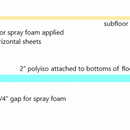

For those of us in climates, such as a warm desert, where a vented crawlspace works, might this be a good way to create a sealed and insulated chamber underneath the subfloor using a minimum of polyiso and spray foam? The attached diagram conveys most of the idea. I oversized the 1/4″ gaps to make them easily visible. Spray foam through the upper gap would pretty much fill that small triangular space. The lower gap would allow foam to form sort-of a thick K shape where the two pieces of polyiso meet. Each piece of angled polyiso would be cut to fit snugly between the webs of the floor i-joists, with notches to allow for the wider flanges, and spray foam and/or caulk would seal the intersections between the polyiso and the i-joists.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I intended this idea more as a contribution than as a question, but if it won't work for some reason, that would be good for me and anyone else who reads it to know.

Jeff, it's a clever idea, and might work fine. In general it's best to avoid interstitial spaces--ones that are not clearly "indoors" or "outdoors," as that's where bad things (i.e., condensation) often happen. A desert climate is pretty forgiving, but if you were in an area with humidity, you could find that air conditioning or heating leaves surfaces below the dewpoint, allowing moisture to accumulate. Another concern is that "cut-and-cobble," a term I believe Martin Holladay coined, may not maintain a good air seal long-term; monolithic spray foam is more reliable, and tapes and membranes are even more reliable. But in a forgiving climate like yours, this may be an effective approach.

Thank you, Michael.

Yes, we desert dwellers are fortunate to be able to leave most of the crawlspace unconditioned, including the little triangle formed by the rim joist, top of stem wall, and hypotenuse of polyiso in the design I proposed. The ground here is teeming with termites, who apparently aren't inclined to build tubes up concrete stem walls, and if they ever did, the tubes would be visible on the bare concrete. Encapsulation of the crawlspace walls would protect and hide them if they ventured upward, not to mention that it would increase, in my case, the amount of space I'd have to heat and cool by roughly 33%. I considered no crawlspace at all, which would have eliminated a huge amount of work, but a slab would put my wood within easy and largely unseen reach of the termites, and the typical solution, poison, was unacceptable on general environmental principles magnified by getting my water from a well less than 60 feet away. A basement would have been beyond my budget. The only other option seemed to be woodless exterior walls, but at the time I had to decide, I couldn't find a source of the kind of blocks I might have wanted that was close enough to keep the shipping affordable.

It seems to me that the place most in danger of air leakage around polyiso insulating the subfloor is where the sheets of polyiso attached to the floor joists meet whatever is insulating around the rim joist area. With the edges of the sheets of polyiso themselves nailed tightly into the joists and also taped, leakage there seems unlikely, but if they were butting up against a blob of foam used to insulate around the rim joist area, random gaps would be present, even if the foam were cut to make it straight, so a small, intentional gap would be needed to apply more foam to ensure a seal. Using much less foam overall by having the horizontal polyiso butt against an angled piece seems much more economical and less wasteful, and the K-shape of the foam that seals between the two pieces of polyiso should stay put without depending on adhesion. The other way to use polyiso around the rim joist area, attaching it to the rim joist, sill plate, and top of stem wall, would use a lot more polyiso and foam, and the step down from the inner edge of the sill plate to the exposed part of the top of the stem wall would be a much fussier detail to cover.

>"Encapsulation of the crawlspace walls would protect and hide them if they ventured upward, not to mention that it would increase, in my case, the amount of space I'd have to heat and cool by roughly 33%."

Cooling & heating loads don't increase by volume. The loads are somewhat affected by sun-exposed above grade stemwall which can be insulated- usually with less foam than what is being proposed under the floor joists.

In much of the desert SW of the US the subsoil temperatures are between 65F and 75F, optimal for "earth coupling" the house to an uninsulated crawlspace floor. Insulating under the joists isolates the house from that potentially beneficial moderate temperature thermal mass which increases the cooling load, and possibly the heating load too.

This map is too crude for design work (your county probably has more detailed well temperature maps), but it gives you an idea of where it might work:

https://www.builditsolar.com/Projects/Cooling/US-ground-temps.gif

But measuring the temperature of the water in your well would be even more precise, eh? :-) Even at 60F subsoil temps it's worth considering earth-coupling.

In termite zones it's fine to install rigid foam on the crawlspace exposed section of stem walls, leaving a ~3" inspection strip of bare concrete. Cutting strips of removable rock wool batt to fill the inspection strip makes the insulation continuous except during periodic inspections (annually is usually fine).

Very interesting, Dana; thank you.

When you say, "Cooling & heating loads don't increase by volume," I assume that depends on keeping the surface area of the conditioned space constant. If I add the exposed crawlspace walls to the conditioned space, they'll lose and gain heat, more so if I don't insulate them at R-30 like my wooden double walls, but I would be trading a floor that has to be insulated for one that's earth-coupled, so figuring out the net effect is complicated.

I couldn't find any soil temperature data for where I live, but by the map you cited, I'm pretty close to the 57-degree line. I assume an uninsulated slab has a similar thermal effect as a crawlspace floor that's part of the conditioned space. When I did heating and cooling load calculations, with a vented crawlspace and an insulated subfloor, using loadcalc.net and yourvirtualhvac.com (now eds.tech), both showed my heating load at around 12,000 BTU and my cooling at around 6800. When I did the same calculation with an uninsulated slab, I got around 18,000 for the heating and 6600 for the cooling. I just went back to those calculators to try an unvented, insulated crawlspace to see how much difference there is from a slab, perhaps because it's exposed around the edges, but loadcalc.net oddly lacks an option for an unvented crawlspace (unless I'm missing something), and the other site no longer offers the same free tool. How much different do you think a slab is from a crawlspace floor in terms of thermal coupling? If one has wooden walls at R30, how much should crawlspace walls be insulated?