PT Sill Plate Shrinkage

Another rookie framing question:

How is the eventual shrinkage of high moisture content PT sill plates typically dealt with?

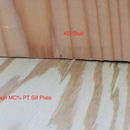

My PT 2x6s are at 35-45% MC, and are ~5 3/4″-5 7/8 wide. If I flush the 18% MC, 5 1/2″ studs on to the outside of the sill plate at the exterior, and then sheath the exterior, I would expect that a gap of 1/8″ to 3/16″ would open up between the sill plate and sheathing once the PT has dried. Or do the nails not pull and the sheathing is able to flex enough in that short distance?

The only counter measure that I could come up with, outside of drying the PT, is to apply heavy sealant at that particular joint…and then just rely on my other sill detailing for any gaps that open up.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

If not too late, use a sill gasket and a non-pt plate. The sill gasket provides a capillary break from the concrete so moisture can't wick up. That is how everything around me is built.

steve41,

The sheathing is fastened to the sill plate @ 6" oc - or closer is seismically active areas. The studs have 3 nails each. If there is going to be anything moving it's likely to be the studs.

I agree with Akos that if possible it's best to avoid wet pt lumber if there are alternatives available, however I wouldn't worry either way. Frame the walls with the sill proud of the studs by 1/16" or so and carry on.

Note that you can get “KDAT” (kiln dried after treatment) pressure treated lumber, although it’s almost certain to be special order. KDAT PT lumber is fully dry, so no shrinkage issues. I think using a will gasket is a better idea though, since the material is easy to get, and it has additional advantages (capillary break, better air sealing).

For now, if you see gaps and are worried about air sealing, polyurethane sealant is good for small gaps, canned foam is good for larger gaps.

Bill

Bill,

Many of the lumberyards here have switched from ACQ to MPS treated lumber. The stuff I get is as dry as the rest of the framing lumber. I used it for my fascias when I redid my roof. It was dry enough to stain the day I bought it.

I've seen some notes about lumberyards around here changing treatments too, but I'm not sure to what. I haven't built anything with treated wood in several years (partly due to the crazy high prices which seem to be calming down now), so I haven't really noticed if it still had that wet "left out in the rain" feel to it. I'll have to go check it out next time I'm in the lumberyard.

BTW, I love the wooded backdrop in your pic. I have similar here, with fewer pine trees these days due to borer beatles (grumble), but still lots of trees, oaks and maples, mostly. We have a lot of larches here too, which will soon be turning their brilliant fall golden color.

Bill

We are on a forested acre of fir, hemlock and spruce. Beautiful except during the night in winter wind-storms when I get a bit nervous.

If you have a few specific trees you're worried about in the wind, you could try guying them. It's easy to do temporarily, just run a line from around 2/3 up the tree you're concerned about, then tie the line off near the base of another tree, ideally the same distance out from the base as you went up the trunk so that the guy forms the long side of an equilateral triangle. Braided dacron rope works well for this, with it run inside garden hose if it will just be loosly tied around the trunk of a tree (the garden hose helps to protect the tree from the rope's movement). More permanent setups would use eyebolts run through the trunk of the tree. Pole line hardware such as is used by utility companies works well for permanent setups.

Arborists usually call this kind of thing "wiring" the tree, and it's sometimes used to help keep large branches from splitting the trunk too. The dacron ropes make a good quick and inexpensive way to temporarily guy trees to help brace them for upcoming wind storms. If you really want to do a quick job just to protect your house, you can guy the side of the tree away from your house, then put a small amount of tension on that line. This will help to make sure that if the tree does fall, it will at least fall away from your house.

There are always some tradeoffs living in the woods I suppose, but they're worth it to not live in the city :-) In my area, the trees are all far enough from the house that I don't have to worry about damage, but we do have a lot of power outages which makes having a generator nearly a requirement.

Bill

Thanks everyone, much appreciated.

Interesting that you mentioned KDAT Bill. I had once sought it for a different project and had multiple lumber yards tell me that there was no such thing as KD PT. Eventually I got a call back and they let me know that they could special order it.

In this case the application is a raised slab inside of stem walls. I'll have strips of Stego, along with sill seal foam and a lines of sealant going under the sill. The Stego strips will eventually be taped to the interior Stego, for a continuous barrier. Given this layering I believe I should be good to switch to a non PT option.

Originally I had defaulted to PT for the sill plate because that's what I see here in Maine, and I figured that I would be "safe".

One other note about the PT sill plate that you may not have thought about, is the shrinkage along the 2x dimension (or mm equivalent). When you install them green, you can tighten down the nuts on the anchors pretty hard, but a month or two later after they've dried out, you'll be able to kick the washer around freely. You need to remember to go back and tighten those once before you close up the walls from the interior.

Good point kbentley regarding the anchor bolt nuts. I had wondered about this as well since the PT is ~1 5/8" thick currently. I'd wager there are a bunch of loose nuts out there. :)

I picked up some KD SPF for the sill plates. Maybe my concerns about the PT shrinkage would never have come to fruition, but there should be less futzing this way.

Thanks all.

Steve,

You'll want to check this on the non PT plates anyways, I've seen it happen, to a lesser degree on SPF lumber too. Part of the problem is the cyclic swelling / drying if exposed to the weather for a while.

I wish we could completely get rid of PT lumber. Maybe we can cross breed black locusts with a cedar, and then cross that with white oak. I've never had a PT board not move to some degree. It's frustrating.

good luck!