Roof assembly with rockwool: need advice

Remodel underway in CZ03C, zip 95060. My design roof assembly is shown in the attachment (unvented cathedral ceiling, inside out: 1/2″ sheetrock, 2×6 rafter cavity w blown-in fiberglass or open cell spray foam, 1/2″ plywood roof sheeting, vapor permeable peel and stick air/water barrier [or maybe just taped plywood seams], 3″ Rockwool Toprock DD, 1/2″ plywood roof deck, Delta Trella vapor permeable metal roof underlay, standing seam metal roof).

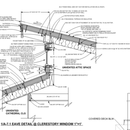

I’m having a hard time sourcing the 3″ Rockwool Toprock DD. I was told today that they could get 2″ Toprock DD. If I reduce to 2″ on hte south roof, it makes more space for my south facing clearstory windows (see detail, cross section looking from the east). On the north roof, I could use 2″ or double stack it for 4″ total.

Based on the minimum thickness required for my mild climate zone, I think I would be fine with 2″ of above deck insulation. Toprock is rated at R-4.3/in, so I’d get R8.6 above the deck.

My questions:

– If I reduce the south roof to 2″,does it make any sense to increase the north roof to 4″? My minimum nominal R- per code is R-30, but I’d love to get higher (hence starting with 3″, which was the most I could get and keep the existing clerestory windows).

– What if I flash 2″ of closed cell spray foam under the deck, and put a mineral wool batt in the remaining cavity? I’m trying to avoid foam as much as I can, but recognize that this new layer would add significant R-value to the assembly. But it would make it so the roof has to dry away from that foam, right? I also like the mineral wool for the fire resistance, but if there is foam in between, does it even help? How else would this affect my assembly?

-Do I skip the whole roof Rockwool idea and go for Polyiso? I’m turned off by the foam aspect, by the insect aspect (termites and ants here), but I bet it would be a bit cheaper (fwiw, I was quoted about $1,200 for the Toprock at 3″, but they added $2,000 in freight).

Any other comments on this assembly are welcome, thank you

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Phil,

Installing semi-rigid mineral wool on the exterior side of sloped roof sheathing is rarely done in the U.S. -- it's more common on flat roofs (though still rare). You will find that (a) your approach is more expensive than using polyiso, and (b) roofers may balk at implementing your plan.

That said, there is no reason your plan won't work -- with either 2 inches of mineral wool or 4 inches of mineral wool.

Q. "If I reduce the south roof to 2 inches, does it make any sense to increase the north roof to 4 inches? My minimum nominal R- per code is R-30, but I’d love to get higher."

A. Sure, it makes sense -- if the higher R-value matches your performance goal (and it sounds like it does). Everyone's performance goal is different -- and everyone's budget is different. The decision is yours.

Q. "What if I flash 2 inches of closed-cell spray foam under the deck, and put a mineral wool batt in the remaining cavity? I’m trying to avoid foam as much as I can, but recognize that this new layer would add significant R-value to the assembly. But it would make it so the roof has to dry away from that foam, right?"

A. The closed-cell spray foam would work, but it would reduce the ability of the lower layer of roof sheathing to dry inward -- so it comes with a drawback. I'd switch from exterior mineral wool to exterior polyiso before I went with closed-cell spray foam between the rafters.

Q. "Do I skip the whole roof Rockwool idea and go for polyiso?"

A. That's certainly worth considering.

Martin,

Thanks for the comments. If I can eliminate the high shipping cost of the rockwool (which might be the case if I go to 2"), then the cost gets much closer to Polyiso, and the roof will have the ability to dry in either direction.

If I switch to polysio, doesn't that limit the ability of the lower layer of roof sheathing to dry outward? Is either direction of drying more important?

If I switch to polyiso and a flash of closed cell spray foam under the deck, what happens to that sandwich of lower roof deck in between; does that increase the risk of rot? This would give my biggest R-value, but I'd lose that drying ability, as well as all the great mineral wool qualities.

Phil,

If you plan to install standing-seam metal roofing, you won't have any drying to the exterior, no matter what type of insulation you install -- unless, of course, you decide to include ventilation channels directly under the roofing.

The type of roof assembly you describe -- with vapor-impermeable roofing, but no interior vapor barrier -- is designed to dry to the interior.

If you decide to install polyiso above your roof sheathing, that choice doesn't imply that you need to install closed-cell spray foam on the underside of the roof sheathing. The usual practice is to install some type of fluffy insulation between the rafters when polyiso is installed above the roof sheathing. For more information, see "Combining Exterior Rigid Foam With Fluffy Insulation."

Martin,

The underlayment I am using with the standing seam metal roof is Delta Trella: https://www.dorken.com/en/our-products/products/residential/delta-trela.php

This has a bit of space for airflow under the standing seam, so while it's not true ventilation channels, it appears to be designed to allow that water vapor to move in both directions. Does this assembly look like it can dry in both directions to you?

If it can dry in both directions even with the standing seam roof cladding, and I end up with mineral wool on the roof and flashed CCSPF below, would the ability of the roof sheathing to dry to the exterior make up for what the CCSPF blcks as far as drying to the interior?

I didn't mean to imply that by installing polyiso, I'd have to install CCSPF under the roof deck; it's more of a 'what if' as far as sandwiching the plywood in between polyiso and CCSPF. I think I've read elsewhere that this sandwich of two vapor-impermeable materials is not a good idea.

Why does the roof deck need to dry toward the exterior?

Unless you install ccSPF on the interior highly permeable cellulose or fiberglass or rock wool on the interior side would have a HUGE drying capacity toward the interior. A couple inches of polyiso on the exterior is more that adequate dew point control on R30 of dense packed fiber in your climate. R23 rock wool batts in a 2x6 cavity + 2" of R5.7/inch roofing polyiso puts it in the mid-30s for center-cavity R, but with the R11.4 thermal break over the rafters it'll beat the performance of R40 between joists/rafters. It's fine to go for more though.

The more insulation there is on the exterior, the less benefit there is to building in capacity for drying toward the exterior. Put the foam budget on the exterior, not the under side of the roof deck where it inhibits drying toward the interior, and provides NO thermal break over the rafters.

Dana, thanks for the reply. I don't think the roof deck has to dry to the exterior. When I get prices on the 2" Rockwool Toprock DD, I'll be able to have a bit of a better handleon cost-benefit of using that versus Polyiso. Hard to let go of the Mineral wool properties (fire, bugs)

You can also have one layer of polyiso (1'') and one layer of rockwool (2'') on top. Polysio R value is temperature dependent so it's good to add some cold tolerant insulation on top of it (although I'm not sure it's a big concern in your climate zone). Plus, foam can shrink while rock wool is really stable so this would help with any potential thermal bridging due to the foam shrinking. And you'll still have all the rock wool other benefits : fire and insect protection, sound dampening (not to neglect with a metal roof).

Thanks AlexPoi, that's an interesting idea. If I did do a 1" PolyIso under the 2" Toprock, would I tape the polyiso seams to make it a true air barrier?