site built baffle and rigid foam question

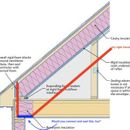

I’m considering a job to improve insulation in Zone 5 by having insulation below sloped roof (rather than on kneewalls and 1st-floor-ceiling/second-floor-attic). The roof is vented, so I’d use a site-built-baffle. When insulating the sloped roof (for visual see picture https://www.finehomebuilding.com/app/uploads/cms/uploadedimages/fine_homebuilding/articles/230/021230089_xlg.jpg), I imagine the insulation between the site-built-baffle (by roof deck) and rigid foam (below insulation material) would be thicker than the 2×6 walls. The foam layers would be around say R-38 batts (12”). I have attached a picture of my situation, where the red lines are my envisioned rigid foam above top plate and below batt insulation for thermal break. The entire cavity could be filled with say batt insulation, but would you use rigid foam and seal the blue piece in my picture? Thanks, and please let me know if I can clarify?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I kinda sorta think I know what you’re trying to do here. I’m thinking your plan, from the roof deck down, is something like this:

Roof sheathing / batts in rafter cavities to fill the cavities / more batts over the rafters to get to your target depth / rigid foam to hold the batts in place.

Sound about right? I don’t see a problem with that, but you don’t necessarily need a rigid foam layer under the batts, you just need an air barrier. The rigid foam will probably need at least an ignition barrier too, so you might be adding a step by using rigid foam here. What I would probably do instead of using an inner layer of rigid foam is to use a layer of thin plywood or OSB to hold the batts in place. There are also some insulation support materials similar to housewrap available. All you need is a material with the right fire ratings that can act as an air barrier and provide a bit of support to keep the batts in place.

Note that I would use more than the code minimum 1” vent space under the sheathing. I prefer to use 2” whenever possible, or 1.5” at minimum. 1”, while meeting code, just doesn’t allow enough air movement in my opinion.

Bill

Bill, yes, you are picturing what I envision.

I attached a picture of part of the current area, and I thought to instead bring this area into the conditioned space. There are basically a couple sections like this with small 3' tall kneewalls (somewhat center of pic) and 8' tall kneewalls (behind photographer). So, sloped ceilings are about 3', 12', 3', 12', and 3' for a total of nearly 30' run. I'm trying to research all the work involved vs. the benefit of doing so. Thanks for the response. If you have other ideas for improving this, they'd be most appreciated. In the past ice dams have been an issue here.

I'm guessing this is a cape cod style home? There are some articles on GBA specific to the insulating/air sealing issues that go along with this type of home. My own home is similar in some ways, so I can relate.

A lot of your issue is probably air sealing. That's the first thing you want to address -- make sure there are no leak paths from the interior to the exterior. Classic spots are between joists near those kneewalls. You also need an air barrier so that the batts in that kneewall aren't exposed -- you lose a significant percentage of the R value of those batts due to convection currents otherwise. I would put some polyiso over the studs on that wall to both create an air barrier and add some R value (as continous insulation!). I would use at least 1" polyiso here, but 2" is better. More R value doesn't hurt here. I would caulk the perimeter and tape the seams between sheets so that you have a good air barrier too. Make sure to seal any holes in top and bottom plates before you put the polyiso up -- I use canned foam for this usually.

You need to make sure there are no major air leaks in the floor of that small attic space.

It may be easier to seal up the wall and floor than to try to convert that small attic to conditioned space. Exactly what is easier to do depends on your particular home and how accessible these spaces are. In my own home, the "knee wall" is about 7 feet high, so it was easier for me to insulate the back of the kneewall and the attic floor than to try to insulate the roof line.

Another thing to check is if you have sufficient intake venting in your soffits. Too little intake vent area relative to your exhaust (usually a ridge vent) vent area and you have slightly lower pressure within the attic spaces which exacerbates any air leaks. If you don't have enough intake vents, cut in some more. My own home had far too few intake vents.

Bill

Bill, yes, cape cod style with dormer and several other transitions. I’ve been reading lots of nice articles on GBA. It might be easier to go with your suggestion. I have easy access to 1” polyiso and 2” EPS (25 psi). Going with your suggestions, if I understand correctly, I’m envisioning:

1.) Put polyiso on all kneewalls (maybe two layers of 1”, as I have access to this for decent price), with taped and nonoverlapping seams, caulked and spray foamed elsewhere.

2.) Blocking with say two layers of 1” polyiso or 2” EPS below 2nd floor kneewall and also above 1st floor top plate (by soffits). Spray foam everything into place.

3.) Look for other potential small leaks and spray foam.

4.) I also envision extending the blocking by soffits to travel 1-2’ along the roof rafters (with 2" gap for venting). This could allow blow-in cellulose to achieve higher R-value on the horizontal without pouring into soffits.

I can seal the kneewalls and insert blocking, as suggested. But, what can be done to better seal the floors? Would my 4) be sufficient? Currently on the floors, there is old mineral wool batts (faced on both sides) with foil faced fiberglass on top of those.

Lastly, I did add intake vents, will finish closing gable vents, and have ridge vents everywhere. I'm trying to balance ventilation (or have more intake than exhaust vents).

Your number 4 is the usual way to deal with the spaces between joists if you don't want to install solid wood blocking. Either way is fine for air sealing purposes. Overlapping sheets of 1" on the larger areas is a good idea too if you have access to the material. I would put a bead of sealant around the outer perimeter of the area being insulated (to create an air seal between the framing and the first sheet of polyiso), then attach both with deck screws and the large, plastic "insulation washers". This alone will make a pretty big difference -- when I did it, I could see the change in the frost patterns on the roof the very next day we had frost after I did the work.

I see no problem with extending the polyiso up above to create a dam for the loose fill insulation on the upper level. I've recommended doing exactly that myself.

Canned foam is great for sealing random leaks. Note that "canned foam" is not the same as two-part "spray foam". I like to distinguish between the two since canned foam has none of the potential issues with curing that spray foam has.

Bill

Bill, thank you, thank you. Yes, I meant "canned foam" to seal around blocking and seal it into place. Now, think I'm just about there and have last couple questions.

When you say "put a bead of sealant around the outer perimeter of the area being insulated", I'm thinking Loctite Power Grab All Purpose (claims to stick to rigid foam and wood) in a continuous bead around perimeter of walls. Did you have something else in mind?

I have a lot of grade 5 (blue/silver) zinc plated 3" screws. I imagine these would work in attic, but it might be better to go with something more corrosion resistant?

I would use a polyurethane sealant (caulk), not construction adhesive, but I suspect the construction adhesive would probably work too.

You don't need anything fancy in terms of the type of screws you use to hold the insulation in place. I think what you have will be fine, as long as they fit the insulation washers. You DO need those insulation washers -- screw heads tend to pull right through the squishy foam insulation without them.

Bill