Spray Foam and Membrane Roof

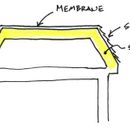

I am an architect designing a mansard roof, so the sides of the roof are going to be sloped and shingled, and the center portion is going to be flat with a membrane roof on it – either EPDM or TPO. The roof sheathing will be plywood on both the angled perimeter and the flat center. Because the attic will be conditioned, it seems spray foam will be a good way to insulate the roof. I’d like some advice on whether to use open-cell or closed cell, and if I should be providing any special detailing for either the shingles or the membrane. I like the continuity the spray foam will provide in the framing, but I’m concerned about moisture getting trapped below the membrane roof and rotting the plywood. I’m in a cold climate 5 – Chicago area. I’d appreciate any insight. Thanks!

Dave

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Closed cell foam is the only safe option in an unvented, impermeable roof in a cold climate. To reduce the climate impact (and probably the cost) you could use a flash-and-batt or flash-and-fill approach; in CZ5 you need at least 40% of the R-value to be in the foam layer. Because this is not a thermal-code-compliance issue but a long-term building resilience and occupant health issue, assume the foam will eventually be about R-5.5/in, not whatever the salesperson tells you it is.

If the spray foam is installed perfectly, cures perfectly and doesn't shrink, and the roofing is installed over dry sheathing, the assembly should be safe. I avoid flat roofs when possible because of the risk of failure.

Alternatively, you could put 40% of the R-value in rigid foam on the outside of the sheathing; that's a safer assembly.

Michael

Thanks for the input. At the flat roof, I had thought of putting the rigid on top of the plywood sheathing (and under the membrane) but I worry about the connection to the sloped roof where the closed cell would be on the inside. Perhaps that's not a big concern. Also, if I supplement with batt insulation under the plywood (where the rigid is on top the plywood sheathing), can those batts be unfaced? I would presume so, since the membrane and rigid would provide the moisture and vapor retarder. I suppose it doesn't matter if the fiberglass batts are faced or not.

I meant to add code links, which lay out the requirements. The older codes are easier to understand: https://codes.iccsafe.org/content/IRC2015/chapter-8-roof-ceiling-construction#IRC2015_Pt03_Ch08_SecR806.1, but the 2021 code is more thorough: https://codes.iccsafe.org/content/IRC2021P1/chapter-8-roof-ceiling-construction#IRC2021P1_Pt03_Ch08_SecR806.1. There have been many, many, many conversations here on this topic so I suggest doing a search, but feel free to ask if you don't find the answers.