Stucco rainscreen – site-made lath or

I come to this from the design side, so I’m not familiar with material/labor costs in the “real world”. I’m hoping some of you can advise on the most economical approach.

The key issue is whether to do a stucco rainscreen installation using site made lath, strips of 3/8″ plywood, versus using products such as Dorken’s Delta-dry type products. I understand the Dorken type products are pricey compared to simple lath, ripped on site from 3/8″ plywood.

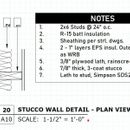

I’ve attached a detail showing the lath. The stucco spec would include a good quality paper-backed lath such as ClarkDietrich’s. The taped insulation face will act as the WRB. So only a single layer of Grade D paper, will be required for the stucco installation.

So, site-made lath vs manufactured rainscreen products – which is your preference and which is most cost effective?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

A lath rainscreen like what you've drawn is certainly more effective at draining than a Delta-dry type product... *but* stucco installed on lath is almost definitely gonna be thinner over the lath strips. This increases the likelihood of cracking -- even if you somehow get the right thickness over the lath, you're gonna end up with a thicker, heavier coat right next to it.

How likely is this to cause problems? I'm not sure. I'm a wood siding guy who considered doing stucco for a while until this and other question marks scared me off. I've helped with stucco installations only on old school buildings with no sheathing... and thus no risk of sheathing rot.

Thanks. You bring up a good point. I've seen 2 approaches to dealing with the problem you've pointed out.

1. Add intermediate laths screwed just to the sheathing, between the studs. At 12" o.c. the stucco-wire would have a better chance of not giving way so much.

2. Add a layer of gypsum or cement board over the rainscreen lath, so that the stucco-wire is fully backed. This sound expensive to me, and seems like overkill

Maybe others can chime in on that as well. Generally more pieces and parts seems to me like more places for things to go bad and more labor as well.

#2 also strikes me as adding a lot of weight, which could be a problem too -- not many people are going to have rainscreen or stucco lath fastener schedules engineered. That's the sort of thing that I often see overlooked in Building Science type details... it's kind of like some of the advanced framing techniques that add architectural limitations and framing difficulties in exchange for truly meager performance gains.

Thanks. Yes, it does sound like a lot of weight. I've read one study/test that leaves me confident the long screws through the furring strips and 2" rigid insulation will be enough support for the weight of the stucco.

Deleted

Deleted

I think what you’ve drawn are furring strips. They hold the stucco off the wrb to provide a drainage plane and ventilation behind the stucco. In that scenario you will still need lath to give the stucco something to hang on. The furring (whether strips or a spun poly product) and the lath are doing different jobs. For furring strips I would use solid wood rather than plywood. The question of cost vs a mesh product will depend on labor/materials balance—I think wood will be cheaper, but the difference is likely negligible in the scheme of things.

Thank you. I see there's a bit of confusion because of my choice of jargon. I've got both plywood "laths" and "stucco lath" (wire mesh). I will use "furring strips" to refer to the plywood lath and will look into a solid wood alternative. I thought there would be less chance of splitting with plywood.

I think the bigger cost save of furring strips over drainable wrap is if you can reduce the insulation thickness (say go for polyiso) to the point that furring strips can be nailed up with a framing nailer. Not having to deal with screws saves a fair bit of material cost and a lot of labour. Even having to buy a nailer that can shoot jumbo nails just for the job will be cheaper than screws. The jumbo nails would most likely split 1x lumber, I would use only plywood furring.