Truss Design for Energy-Efficient Shed

The time is getting close to start construction on my energy efficient shed. Some quick background:

– 8’*12′ (can’t build larger for building code reasons)

– Pacific Northwest (climate very similar to Seattle but a little colder)

– I want to be able to store stuff in the shed throughout the winter that cannot freeze.

– I will be insulating the shed and hope to keep it from reaching freezing inside with a minimal amount of energy (e.g. turning on a 100 Watt lightbulb whenever it is going to drop below freezing – ideally hooked up to an anti-freeze thermostat.)

– Basic plan is for 6″ walls insulated with rockwool and a vapour barrier on the inside. 6″ or 8″ insulation in the floor and the attic. No plans for external insulation.

– Attic will be vented (soffit vents and a ridge vent)

– Passive de-humification (moisture absorber such as DampRid as needed)

– No windows or vents. Air tight. Single insulated steel door.

I’m designing the trusses now. I want to have a minimum of 6-8″ of insulation wall to wall.

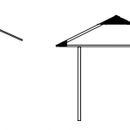

I looked at the possibility of building Raised Heel/Energy Trusses but it looks like it complicates things significantly. (Option on the left of the diagram)

So I’m now proposing the option on the right of the diagram. I’d use gussets on all three corners. The bottom 2*4 sits directly on top of the wall. It seems like this hits all the criteria:

– Easy to build (no birdmouths, etc.)

– Seems like it would be adequately strong in all the required directions.

– Gives me height above the top of the wall to install insulation while still allowing an air gap above.

Am I missing anything? Any suggestions? Seems too simple – and I haven’t seen others done like this – what am I doing wrong?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You've got a lot of freedom in design when the roof spans are on the order of 8 ft. It can probably work. If not freezing and space efficiency were your goal, i think you could do better with about the same money - though it involves insulating the outside, which you said you didn't want.

A 2x4 wall with 1" polyiso or xps and regular fiberglass cavity insulation has a higher effective R value than a 2x6 wall with rockwool insulation. Any choice of siding can be nailed through it to the studs, just like normal, with slightly longer nails. It gives you back a little space too.

I ran those through the calculator (albeit assuming the external would be 1" rockwool comfortboard) and the 2*6 walls came out on top. It's also a little quicker to build and less risk of excess material at the end of the day due to minimum package sizes.

Are these calculations wrong?

CD,

I'd stick with 2"x6"s. Depending on what you are thinking of for siding and roofing, I'd also consider eliminating the sheathing and just strapping with 2"x4's.

My default plan was:

Plywood or OSB sheathing on the outside.

Tyvek

Furring strips

Hardieboard shingle siding

Are you suggesting I could go:

Tyvek

Furring strips

Siding

?

Yes. I suggested strapping in case the siding was being installed vertically.

CD,

They're not wrong, it' will come out close - polyiso has an R value of about 6.5, which is about 2.5 higher than rockwool. It would come out to about R17.5 in that case, vs the 18.5 in the 2x6 case. R1 is in the noise of what the heating requirements would be in that scenario. We're talking a countable number of watts.

It is a very small space you are trying to keep warm. Do no overbuild it just to save a few dollars. Keep it simple and add a little more heat.

What are you doing with the floor?

Yeah it's a trade-off for sure. We got to about 14 F this winter so it is not entirely trivial to keep it above freezing without spending a bunch on electricity. I'm trying to stay focused on simple things.

For example:

I can use 2*6 on 24" centers vs 2*4 on 16" centers. I can then easily put 6" insulation in the walls. That is a small change that won't cost a lot or add a lot of complexity to the build. I had thought of using a double-stud wall, thicker wall or external insulation but those are all much more complicated.

This roof modification may actually make my life a lot easier and doesn't really add much material.

I'm still working on the floor design but this is what I have in mind:

The outer frame will be 2*10" I will then hang 2*8 joists so they are flush with the tops of the 2*10" rim. I will nail pressure treated plywood to the bottom of the 2*8 joists. I'll fill the cavities with insulation and then put down a plywood floor and some type of linoleum on top of that.

When looking from the side, the bottom of the 2*10s will be a little lower than the bottom sheet of plywood so I'll be able to easily place it on some concrete blocks/shims as required to get it level. There will be some air space underneath the shed and in theory, it will be possible to move it in the future.

Considering your original question, yes, you can do the truss like shown in the right diagram, because your spans are so short. You wouldn't be able to do this with longer spans and/or on a real house because the lower chord of the truss is exposed to both bending and tensile stresses and truss designers really don't like bending stresses. To make a simple truss into a raised heel truss, you would just add a vertical member above the wall plate. For a longer truss, you would also have a diagonal from the top of the heel member to prevent bending stresses in the top chord, or something like that.

Thanks! I couldn't figure out why this design was not used in real houses. That makes perfect sense. I think given the sizes involved, I will be OK on this one. It would be very easy to add a diagonal brace so I may do that as well.

CD,

The gussets provide a moment connection. Triangles are geometrically stable, so no reason to add diagonal braces.

An energy expert friend was involved with what was called the "Snug Shed" quite a number of years ago. I believe it was built in New York state. Can't find anything on it today but it was superinsulated and was earth coupled via perimeter rigid insulation dug into the ground. As I remember the internal temperature got no lower than about 45F during the winter. The heat from deep Earth kept the temperature in the shed well above freezing.

I thought a lot about doing something similar. If the only goal is to stay above freezing, using the little bit of warmth from the earth has a lot of merit. However, due to site limitations and the need to be able to move it in the future I need to make this one above ground.