Any value adding extra insulation to unvented flat roof?

Hello GBA. We have a small section of unvented flat roof in our project and I am wondering if there is value in adding extra insulation inside because we have a cavity.

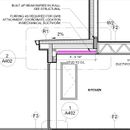

The architect’s plans called for approx. R50 as shown below, I don’t know if the builder followed their detail as they might have had a better way to do it. I do know there is rigid insulation on top of the sheathing and the spray foam below/inside as called for. Wish the architect had listened that we didn’t want spray foam aside from gaps where necessary. The main gabled roof has a vented attic with ~ 18” cellulose for total of about R-80.

Sheetrock is going on the ceiling Monday. We added R16 mineral wool sound attenuation in the joists and I noticed something odd. We’ve got insulation in the basement ceiling, the main floor ceiling, but the only spot without ceiling insulation is where the flat roof is. Is this not the one spot we really need insulation? I’m happy with the sound reduction between levels, but we have extra mineral wool we will be returning and this uninsulated ceiling section.

In the flat roof area there is spray foam above the OSB in the photo. Looks like 2x4s or 2x6s to attach the Sheetrock. It seems fairly obvious to me that we should add some R22 here, am I wrong? I don’t know too much about this stuff so I could be way off! Any heat escaping in the winter is going to heat the membrane surface which will be holding snow load off the main roof. R50+R22= approx R72 which seems good.

We are in CZ 6. This section of roof is over the kitchen so heat and humidity are expected to be higher than other areas of the home.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Izzza,

I have a much larger flat roof bump out with similar details. If the combined above sheathing and below sheathing insulation adds up to nominal R-50, I would leave things alone. You have two ducts and two light fixtures in the "false ceiling" created. The lighting may not allow for insulation contact. The closed cell (?) foam above the OSB should prevent condensation risk at the roof sheathing layer. Adding more insulation under the OSB would tend to drive the cold point in the stack up into the spray foam layer. The thermal gains would be trivial in the grand scheme especially with all the window area.

I hope that you are not in a high snow fall area or that this short flat roof does not face north. Otherwise, the wall above the bump out will be at risk.

Thanks. We have insulation in the rest of the ceiling with the same ductwork and light fixtures so I don’t think there will be any issue there, plus the extra rockwool is already sitting like 10 feet away from this.

The wall above is definitely at risk, which is one reason the design does not seem great. I think our location gets an average of about 295cm of snow annually (116”). I suppose it’s all relative but this seems fairly snowy… the main roof has a massive gabled roof and though this flat section is on the south side, it’s holding load falling from above. There is another small flat roof just over the entry area, on the west side, so the wall above this is also at risk.

Can you explain what you mean about extra insulation driving the cold point into the spray foam layer?

Izzza,

I don't think it makes any appreciable difference whether you do it or not. Pop it in. There is certainly no harm.

IZZZA,

Regarding the "cold point", my not very proper description of where the design dew point occurs in wall and roof insulation profiles. A very simplistic analysis of the temperature profile for a solid foam wall or roof would show a linear rate of temperature shift. If your outside temperature is 0F and the inside is 70F the temperature of the insulation would theoretically be 35F half way through the thickness. If you had a 6" thickness that point is 3". If you have a 12" block that point is 6". Real life is much more complicated.

35F is a very cold surface for any interior moisture level. Think of a glass of iced tea for reference. In my own design, I used 50F as the coldest point I wanted my sheathing and roof decking to fall to when there is a -15F outside temperature. All my exterior insulation for walls and ceilings follows the approximately 60/40 guide for R value distribution outside/inside of the sheathing/decking to control for condensation risk. I designed to be vapor open to the interior, which allows for unfaced batts in the stud and joist bays. Lots of reasons why I went this way.

Your cross section views seem to show that the OSB is attached to the bottom of the roof joists which are filled with CCF to an R-42 level. Closed cell prevents warm interior moisture from reaching the roof sheathing under the tapered insulation supporting the modified bitumen roof membrane. The expected temperature profile for this build up would not be acceptable if CCF had not been specified. The roof sheathing is well above the half way point for your insulation profile and will be quite cold for much of the winter.

Currently you are ok regarding interior moisture issues and the current interior surface temperature of the OSB is room temperature. However, in my opinion, adding the additional R-22 batts you have on hand would make your finished ceiling the new start point for a temperature profile and make your mid point much closer to the OSB side of the foam. Not likely a very great danger unless you routinely see sub zero temperatures for long periods. Just the same, for the very small number of BTUs saved I would not do it. Realistically, you have lots of glass losing far greater amounts of energy.

Ten feet of snow is definitely a lot of snow. Of course I know it doesn't all arrive at once or stay the whole winter. I was reacting based on my own situation where the snow fall from my north roof accumulates on the ground and it does stay until mid-April. Some years the snow will build up enough to contact my stucco. No damage yet and a sub surface drain is placed right at my drip line, so melt off is not migrating down my foundation.

My flat roof section over the living room (and patio for the second floor bedroom) got flashed to a much lower height than I planned. Fortunately, my dry climate means snow fall is about half yours. Being very dry snow it typically melts off very quickly. I don't get added snow from the second floor roof and the main exposure is to the east and south. You might not see much snow stay long enough to pose a problem. I would still be mindful of drifting or other conditions that leave the snow in long contact with your cladding.

Onslow,

If the dew point stays somewhere in that R-42 of closed-cell foam whether you add R-22 of permeable insulation below or not, what does it matter? How is the assembly conceptually different that either assembly #3, or #5 in this link?

https://www.greenbuildingadvisor.com/article/five-cathedral-ceilings-that-work

IZZZA and Malcom,

Izzza asked me to clarify my imprecise "cold point" reference so I did. It is merely my preference to suggest leaving the OSB as primary temperature surface given the location in the kitchen which will tend to have higher humidity levels than other parts of the house (excluding baths).

If the batts are installed for a total of R-72 , 60% of insulation or R-42 should be above the OSB. The plans call for R-50 as the combined value of the CCF and exterior tapered insulation.

So, yes there is likely no problem.

However, I can't see how well the foam was sprayed and if the fill is gap free everywhere. The R-22 batts will only net a trivial reduction in heat loss for that particular area, so why not leave the OSB nearly as warm as the ceiling and not have to wonder if a hidden cold spot exists.

I unfortunately cannot see the prime article you referenced, but the 145 comment chain was entertaining and only shows that many ways and thoughts are out there. No fight here.

Deleted

I don’t believe 18” of cellulose is r-80.

https://cellulose.org/how-to-calculate-r-value-of-settled-cellulose-attic-insulation/

Even if that is settled thickness.

Good point! 18" was the original depth I think they did more though in order to achieve higher R-value for not much extra $.