An Environmental Product Declaration (EPD) is a summary of the many ways the production, distribution, use, and disposal of a particular product can impact people and the planet—topics of interest to an increasing number of consumers. Is a product high in embodied carbon? Is it made with renewable materials? Will it degrade atmospheric ozone? An EPD should answer these questions, making it easier for consumers as well as product specifiers to make the most appropriate choices.

For help in understanding how EPDs are created and how to find and interpret them, we turned to NSF, an organization founded in 1944 as the National Sanitation Foundation that has since grown to develop public health standards and certification programs in a wide range of industries. GBA spoke with Justin Brown, a senior technical reviewer for sustainability, via email and video.

The Swedish Environmental Protection Agency created what became the International EPD System in 1998. EPDs are based on a life cycle assessment (LCA) of a product that examines everything from the acquisition of raw materials and manufacturing to disposal, what’s called a “cradle to grave” assessment. EPDs are voluntary; no one forces a particular manufacturer to write and verify EPDs for the products they sell. But, says Brown, demand is growing for EPDs from both public and private interests as environmental concerns deepen, and that’s driving up the number of EPDs that are available.

There are four steps in creating an EPD, beginning with product category rules, which set out the basis for measuring the environmental attributes of products in a certain group. That’s followed by an LCA and an EPD, both written by the manufacturer with or without the help of a consultant and specialized software such as GaBi or SimaPro. This information is verified by an independent third party (such as NSF), which reviews both the LCA and the EPD itself to make sure they conform to one or more ISO standards. In the U.S., ISO 14025 is the standard for building products; in Europe, it’s EN 15804. (The International EPD System offers an explanation of the process here.)

Asked how an end user knows that the information in an EPD can be trusted, Brown said in an email: “The EPD document and accompanying LCA is verified by an approved individual verifier or an accredited certification body with knowledge and experience of the types of products, the industry, and relevant standards of the product covered by the EPD and its geographical scope.”

In a nutshell, manufacturers do the homework and an independent verifier makes sure the results are accurate. Everyone works from a standardized script, with specialized software speeding up and organizing the process.

What an EPD can tell you

There are, Brown says, two kinds of EPDs. One is a single-company, single-product EPD, the most common type. It describes the life cycle environmental impact of one product from a single manufacturer, or very similar products from a single manufacturer. One EPD could describe products made in one of several factories. When a single manufacturer makes the same product in plants in different locations using the same manufacturing process, they can be covered by a single EPD.

The other type of EPD covers a general product category. These are developed by an industry association or trade group and describe an “average” product made by a number of companies in a clearly defined category or geographic area. Industry average EPDs can sometimes be found at the website of the appropriate trade group. The Resilient Floor Covering Institute, for example, lists a number of EPDs for flooring at its website.

EPDs can help consumers choose products that are most appropriate for them, but the ISO standard explicitly warns against using product-level EPD for direct comparisons between one brand of, say, countertop or flooring and another. Why? Because, says Brown, there are so many differences in materials and manufacturing that direct comparisons can be misleading unless you know exactly what you’re looking for. Unless you’re well versed in how to read and interpret the information, nuances may be overlooked or misread.

“One product could be better in the raw materials extraction phase but worse in the processing phase,” he said, “so it’s hard to flesh that out to determine, especially for a layman, which one is better overall.”

Even so, consumers are going to compare the EPDs of competing products. And, said Brown, there’s no reason that a consumer can’t do that to make a choice based on the criteria that are most important—embodied carbon in the manufacturing process, for example, or the percentage of non-renewable materials that go into a product.

While ISO standard discourages comparisons of product-specific EPDs, it makes no warnings about comparing industry average EPDs. Side-by-side comparison of these documents can provide some interesting, if generic, information about such things as global warming potential, ozone depletion, and depletion of non-renewable resources like minerals or fossil fuels. If you want a rough idea of how rubber flooring and homogeneous vinyl flooring stack up on those issues, the EPDs are very useful.

Are EPDs getting too complicated?

There is a lot of detailed information in an EPD, not all of it comprehensible to an average consumer. Let’s look at the EPD published by Tarkett for its line of linoleum flooring. It includes a lot of useful information about linoleum—What’s in it? Where do the raw materials come from? How is it made? The basics all seem straightforward.

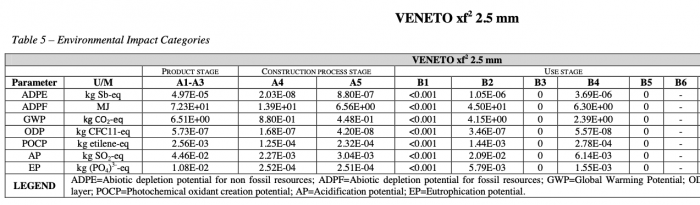

Yet other parts of this 30-page EPD may look more like alphabet soup to the untrained eye (see the illustration below). If you know what you’re looking for, and you’re trained to interpret the data, the information will be there—the global warming potential, ozone depletion potential, or use of primary energy resources in the raw materials. For average consumers or builders, the meaning of the data is likely to be obscure.

The situation is growing more complex because the ISO standard used in the U.S. and the EN standard used in Europe are becoming increasingly different, Brown said. The new version of EN 15804 is apparently going to be much different than its predecessor, forcing companies that intend to market products in both North America and Europe to add lengthy addendums or write two separate reports.

As originally intended, Brown said, an EPD was a quick, easily digested reference on the environmental impact of a product. What happens when it becomes a much longer document loaded with technical information?

“The general public is going to look at a document like that and throw up their hands,” Brown said. “They’re going to have no idea. An architect, an engineer, a builder—they’re going to have a little bit more. They may be able to go through there and find what they need. But if it’s a 10-12-page document I don’t care who you are, it’s going to be difficult to decipher what’s in there. And I don’t think that was the original intent of an EPD.”

More specialized reporting tools can help narrow product research. The BEAM Estimator, developed by Builders for Climate Action and the Endeavour Centre, and the EC3 tool from the Carbon Leadership Forum, both are designed to assess the carbon footprint of different building materials. Builders with a focus on embodied carbon may find these calculators all they need.

Where to find EPDs

For product-specific EPDs, visit the manufacturer’s website or enter the information you want in your favorite search engine. For example, to look for the EPD of a quartz countertop material called Silestone, I entered “Silestone EPD” in the Google search engine and was able to track down this document quickly. If you want to compare that to a competitor, despite the ISO’s warning that you don’t, try plugging in another trade name. But keep in mind that because EPDs are voluntary, not all manufacturers offer them.

As Brown suggested, industry-wide EPDs may be available at the website of the sector’s trade association. The Canadian Concrete Masonry Producers Association and the Resilient Floor Covering Institute are two examples. However, not all trade groups offer them. If not, try calling the trade association and asking where a link to the EPD can be found.

Finally, you can check directly with an EPD verifier. NSF maintains a directory of EPDs for products it has verified here. UL has a similar database here, as does the website of ASTM. This method is hit or miss because most consumers wouldn’t have any idea which certifying agency a manufacturer would have used. But with a little sleuthing, an EPD will turn up—assuming the manufacturer has taken this step forward.

Scott Gibson is a contributing writer at GBA and Fine Homebuilding magazine.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in