Concrete is the most common building material in the world. We produce billions of tons a year, but at a huge environmental cost. The quarrying and processing necessary to produce concrete is estimated to produce from 4% to 8% of total CO2 emissions. It’s an incredibly useful material though, and frankly, working with it is one of my favorite parts of building. The stuff is magical—it pours into forms like pancake batter, and a couple of hours later you can walk on it.

Apart from those two aspects, we tend to take the stuff for granted.

Concrete has been around in various forms for a long time. The Romans used it in monolithic placements, and the Minoans and others as mortar before them. Roman concrete has a reputation even today, as evidenced by the 2,000-year-old concrete Pantheon dome. Roman concrete isn’t chemically much different from what we use today. It’s a blend of aggregates (gravel down to sand), a pozzolan, water, and calcined lime. The pozzolan and the lime react with water to form a cement that binds the aggregate together.

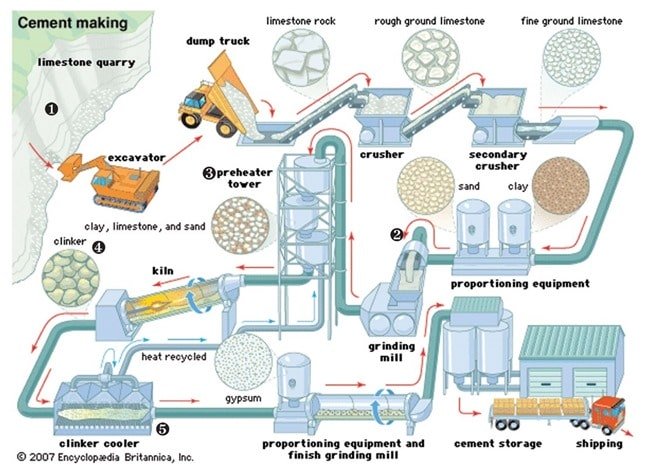

Aggregate is easy to understand. Rock is blasted from the earth, crushed, graded for size, and washed. Sand is mined. The pozzolan and calcined lime are the mysterious components.

What the heck is a pozzolan?

Pozzolans are aluminosilicate minerals, essentially compounds of aluminum, silicon, and oxygen. Many occur naturally. The name comes from Pozzuoli, a city located in a volcanic caldera along Italy’s west coast. Certain types of volcanic ash are pozzolans. The pozzolan in Roman concrete is volcanic ash.

Clay and shale are pozzolans. Diatomaceous earth is a pozzolan. Pozzolans can be artificially made, too. Ash from rice hulls is a pozzolan. Blast furnace slag and fly ash from burning coal are pozzolans, and are…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

8 Comments

Where does the CO2, that is injected into the concrete, come from? Is it like hydrogen in that it has a wonderful end state ie Hydrogen = water, but takes enormous amounts of energy to get to that end state?

That company's goal is to take CO2 that's been captured (that would otherwise have been dumped in the atmosphere) and sequester it away. There isn't currently large scale functional carbon sequestration that I'm aware of, but this is making sure there will be something to do with the CO2 if we start capturing it.

Are there any practical alternatives to concrete, other than just making do with less of it? There was an old episode of Grand Designs that had a (somewhat disastrous) limecrete foundation as a lower carbon alternative to concrete. It seemed the issues they experienced were more in the application than the product itself (and in the end the foundation did work out). From a search, it looks like similar products have caught on in some capacity in the UK. I'm not sure how much lower the embodied carbon is (I think the answer is somewhat - but you may need more mix than with concrete?).

The Grand Designs episode was episode 7, season 5 (viewable online) if you're interested... super interesting show if you haven't seen it!

That is a great show, jkonst. In terms of alternatives to concrete, Blue Planet is a company I have my eye on. Their technology makes for a fascinating read.

This is really interesting, thanks for sharing. I'm about to embark on a Passive House build (with a PH-focused architect/builder), and reducing the carbon that goes into the build is a focus for me. Solving the concrete part of the puzzle is not a simple task!

Please see my comments below. If you are talking about residential and light commercial, wood pilings, or pole style construction is widely used in many areas, particularly in coastal areas ( pilings). These methods are much cheaper and easier than a fully excavated masonry foundation. Of course this essentially eliminated basements.

Much more difficult to replace concrete in commercial and industrial structures. There reducing the amount and using more CO2 efficient blends EY are the more likely route.

Great article. Interesting reference to Edison..My neighbor in Sussex County NJ owned the Zinc mine in Ogdensburg, NJ Once owned by Edison (they turned it into a mine museum). They excavated part of the property and discovered a massive concrete foundation To a now gone building that had been designed and poured by Edison. I believe it is one of the first in the world to have used this type of construction method. So Edison was a pioneer in using concrete for massive foundations- obviously large modern buildings depend heavily on such foundations.

As for residential construction, I love concrete as much as anyone and still do some for fun. But I believe we have a moral obligation to reduce our carbon footprints. Frankly there is little need for concrete or masonry in residential construction. Hundreds of thousands of houses are built on wood pilings (e.g. virtually every new house in the East Coast shore communities). These need virtually no concrete at all-as bearing strength comes from friction on the piles as they are driven into the ground and lateral strength comes from wood bracing and beams. Inland, pole barns and homes built in a similar fashion are all over America. They only use concrete for small footings under the poles. Those who are wary of pressure treated chemicals can use fiberglass pilings or poles. Of course other forms of pier and platform construction are also available with varying degrees of concrete used.

Were it not for global warming I would be a huge proponent of concrete as it is a magical substance as you so rightly state. But how can we ignore the dire state of the Planet?

We are using so much concrete that some types of sand are becoming endangered in parts of the world (sand theft is a thing). Can't just use beach sand, or desert sand, needs to be angular sand or concrete won't develop proper strength.

Fun fact: Burj Khalifa, worlds tallest tower, in the middle of the desert in Dubai was built using sand imported from Australia.

Log in or become a member to post a comment.

Sign up Log in