A GBA reader named BuildingFun is having no fun at all after spotting a potential moisture problem in a cathedral ceiling that’s virtually finished.

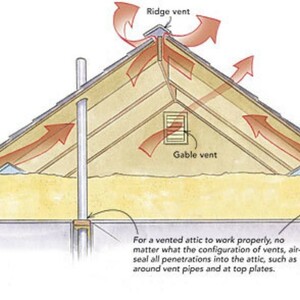

He writes in this recent Q&A post that his old go-to was an unvented cathedral ceiling (sometimes called a “hot roof” design). But he’s decided to switch gears and go with a vented roof assembly. Accordingly, he installed SmartBaffle ventilation channels made by DCI Products between the roof deck and the mineral wool batts in the rafter bays. The corrugated plastic baffles provide a 2-in. air gap for ventilation.

It all looked good, until some last minute wiring gave him an opportunity to look inside the assembly—and he didn’t like what he found.

“I built the entire ceiling, changed the attic venting to a ridge vent and correct soffit ventilation,” he says. “It was lots of work that I wouldn’t do with a ‘hot roof’ and I felt good about the end product . . . until I did a spot check and found lots of condensation on the underside of the smart baffles at night time.”

The moisture disappeared by midday as temperatures rose, but the idea of accumulating moisture in the roof of this San Diego (climate zone 3) home is troubling, to say the least.

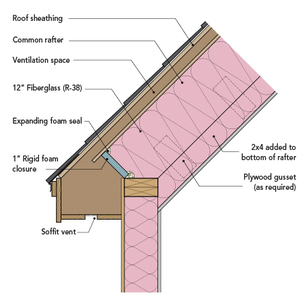

BuildingFun is thinking about starting all over by replacing the baffles with perforated 1-1/4-in. SilveRboard graphite polystyrene. “The way I see it, this SilveRboard XS graphite foam board should eliminate or minimize condensation and hopefully allow any moisture that does accumulate to escape slowly through the board and up into the air channel,” he says.

The roof assembly includes tongue-and-groove ceiling boards followed by a layer of 5/8-in. drywall (a fire barrier), a layer of 3/4-in. plywood, and 7-1/4 in. of mineral wool insulation…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

9 Comments

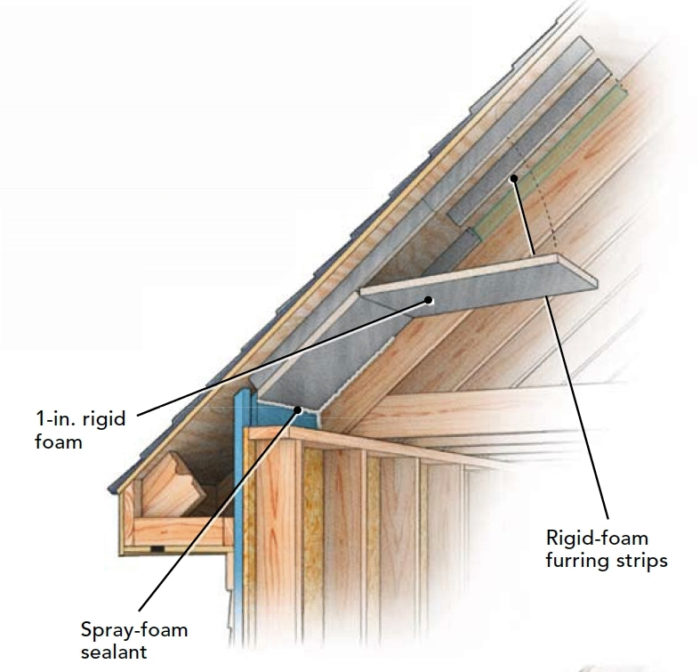

I have been using the fiberboard vent channel for years on vaulted ceilings. With either blown or batt insulation you are enclosing the insulated rafter space, minimizing air movement within the insulation. The fiberboard is moisture permeable to the vent space, a winning setup. For dimension lumber or TJI rafters a taped layer of polyiso on the room side in cold climates will make for a high performance ceiling.

Doug

Kohta's link highlighting the mold issue for coastal climates ( https://www.rdh.com/blog/re-thinking-ventilated-attics-how-to-stop-mold-growth-in-coastal-climates/ )

more or less highlights the issue that the OP is facing. Having a permeable baffle with some r-value does make a lot of sense here. I'd be interested in the 1/2" fibreboard specs used in the project referenced in that link.

Even in an externally insulated roof deck, comments from users in similar climate zones have alluded to the condensation that occurs in the furring strip gap, and the need to allow an escape for condensate via furring strip orientation. The question from the OP was a good one and highlights the fact that research for this particular challenge is ongoing.

One point I didn't see mentioned is that part of how an impermeable baffle can be OK in many applications is that it's often in an attic with loose fill insulation on the floor. In that case, there's lots of room for vapor to escape from the top of the insulation, despite being blocked from escaping the sides.

I asked this exact question a few weeks ago elsewhere on this site regarding using rigid foam for baffles in a vented cathedral.

Thinking about it after reading this article, I feel fiberglass faced gypsum sheathing would be ideal for this job. It cuts like traditional Sheetrock making it easy to create rips and make install simpler. Can also be stacked on a cutting table outside and ripped with a circular saw.

It installs like any other sheetgood. It has good perm, has good water resistance. Has nothing really for mold to eat. Takes caulks well. Will easily span 16-24" oc cavities. Is non combustible.

While it doesn't contribute to thermal performance like rigid foam, I feel this is probably what I'll be using on my personal project.

“[Deleted]”

Sayn3ver, I think that would perform extremely well. The downsides I see would only be cost, and the fact that it's much heavier than fiberboard, making the installation heavier work.

Agreed although I suppose it depends on the project. In my town bungalows are pretty common (1.5 story that typically is just a plain gable roof atop a rectangular ranch house that they use the attic for a room).

If you have a floor to work off of I don't think 16"x48 or 96" rips are unmanageable.

The seams can be taped and mudded or mesh taped and a liquid flashing product used or just flashing taped. The joints can be finished with something like great stretch or other quality caulk.

Fiberboard isn't readily available in my local area in nj. I have called around while working on my personal home years ago. It was built in 1960's and has no structural wood sheathing. It has let in corner bracing, 1x4 horizontal strapping with 1/2" asphalt fiberboard. The previous owner had it resided in vinyl at some point so it has tyvek then vinyl lap over the fiberboard. I needed a sheet for repairs and couldn't locate it without a special order.

Sorry for jumping into this late, but has the issue identified by the RDH research linked here been solved and written up anywhere? I’m in the PNW and have heard of this issue, but can’t seem to find an agreed upon solution. I’m in the planning stages of a restoration and keep getting told vented is best, but feel iffy given this research.

Regarding the permeable baffle, what makes this dry better if the stagnant attic is near the same temp because you have a ton of insulation with great air sealing on the ceiling diaphragm. (Sorry to be ignorant, but I’m not seeing the deltaT or deltaV that will drive this condensate to the other side of the baffle)

As a side note, being new to the PNW, when I talk about the RH, I keep getting told from people in other CZs how RH is irrelevant in colder weather. I understand that there are fewer grains of water possible in the air, but when you spend many hours 1 degree above DP, stuff gets soggy, even in the cold.

spraggins,

Nighttime solar radiance can cause some mold to grow on the sheathing of what we would call well-built and ventilated roofs in the PNW. However, my experience has been that in the absence of other problems that growth is superficial, and causes no damage.

Log in or become a member to post a comment.

Sign up Log in