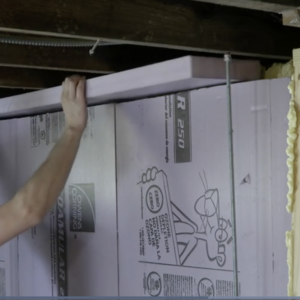

Jeff Smith is building a house in North Dakota and is far enough along to have installed insulated sheathing on the exterior. He’s chosen Zip R6 sheathing, a product made by Huber Engineered Woods that combines OSB structural sheathing and rigid foam.

“Our intent was to create a tight, energy-efficient home, and to deaden sound,” Smith writes in a post at the Q&A forum. “However, now that we have the sheathing on and are siding, I have read people stating that R-sheathing is not well suited for cold climates and that we should have used a thicker foam and placed it on the exterior side of the sheathing.”

His concern is moisture. When a continuous layer of foam on the exterior of a building is too thin, the risk is that moisture making its way through exterior walls will condense and freeze on the inside face of the sheathing during the winter.

“So my question is this: What should we do, at this point, to ensure our walls do not have moisture issues or that they dry appropriately when moisture does enter the wall?” Smith asks. “For what it is worth, the siding is LP Smartside.”

That’s the topic for this Q& A Spotlight.

Right church, wrong pew

Zip-R can work in Climate Zone 6, but it would have been better to choose Huber’s R-12 version rather than the R-6, Michael Maines tells Smith. However, because the inside of the walls is still open, a solution is still very much within reach.

“You can add closed-cell spray foam to the interior to create a flash-and-batt detail. Just make sure at least 35% of the R-value is on the exterior,” Maines writes. “A riskier solution that could work (no guarantees) is to install a variable-permeance membrane…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

14 Comments

Since Peter Y and Allen Sealock confirm, "it is completely allowed by code to build a 20+5 wall in Climate Zone 6 as long as it has a Class I or II vapor retarder..." why all the hand-wringing? The wall as originally conceived 1. meets code, and 2. doesn't run afoul of moisture-management principles. With the foam insulation on the inside of the structural sheathing there is nothing slowing drying to the outside should interior conditions lead to high moisture at the sheathing. And with a relatively warm and low-mass surface facing the interior of the insulated cavity it seems the conditions for condensation on the foam would occur for short duration. Again, why the hand-wringing?

> It is how much insulation is needed to keep the first condensing surface above the dew point.

This is one of those myths that won't die, despite being easily disproved with simple math. "minimize condensation" works. The distinction is important when someone comes up with things like "why would I use cellulose to absorb and distribute condensation when there is none".

Using less foam causes even more condensation. It's not a given that it will perform OK.

There are a couple options that Jeff can take to meet code, but this means little about moisture performance. The more difficult question is "which is best and by how much?"

Response to Comment #1:

User-6890838,

Most building scientists agree that when designing a wall with exterior foam, the most robust designs include (a) exterior rigid foam that is thick enough to keep the first condensing surface above the dew point for most of the winter, and (b) are vapor-open to the interior to allow rapid summertime drying.

It's also possible, however, to include an interior vapor retarder, in order to try to balance the moisture accumulation rate with the drying rate. Whether or not this second approach is as robust as the first depends on your perspective, I suppose. For a full discussion of these issues, see "Rethinking the Rules on Minimum Foam Thickness."

We built our house in Climate Zone 5 (Colorado). We used the R-12 from Huber and our structural engineer required us to screw the panels to our frame using 4" structural screws every 6" on the perimeter and 12" in the field. I think we would have needed 4-1/2" nails per the Huber instructions. I'm not too sure how doable that would have been. No guns and no nails that size. Needless to say, the framer was not having any fun with that. In addition, because the screws heads were not flush with the OSB layer, it made it very difficult to use the Zip Tape without air bubbles in it. I would definitely suggest using the liquid applied if using the R12 product from Huber. Or, doing a nailable Zip-R panel with a flash and fill system as suggested in this article.

i used a Bostich BRT130 to nail my zip-r sheathing. It will shoot a 5" nail, ring or screw shank.

It would be very interesting to see the cost difference b/n 5 inches of closed cell spray foam and the flash and batt... might be the best approach given the current situation to mostly fill the 2X6 wall assembly with Spray foam and sleep easy knowing your walls are not providing a condensing surface anywhere inside.... once you go down the spray foam path - might as well go all in...

Except that the 5" spray foam in the stud cavities with no exterior insulation does not address the thermal bridging that exterior foam applications address. In my house, we decided on a flash and fill method in a floor assembly because adding the extra spray foam was quite a bit more expensive than using the flash and fill method.

That's right!

Installing 5" of closed cell foam in a 2x6 wall cavity is roughly equivalent to 2x6/R20 studwall + R2 continuous insulation (which doesn't even meet IRC 2015 code minimum performance in climate zones 6 or higher, truly UNDER performing for a house in North Dakota. )

See: https://www.greenbuildingadvisor.com/article/installing-closed-cell-spray-foam-between-studs-is-a-waste#comment-form

https://www.finehomebuilding.com/membership/pdf/184243/021269086NRGnerd.pdf

5” spray foam in addition to the 1 inch of poly is in the zip r already on the house in this situation

From a moisture performance perspective it'll do just fine. At 5" the closed cell foam is also adding considerably structural rigidity.

From a thermal performance point of view it'll be comparable to 1.5" of exterior polyiso on an 2x6 / R20 wall after thermal bridging.

Ahhh the back and forth with supplied literature hurts my head.

I'm in zone 6 in Atlantic Canada and I followed Huber's advice with the table 20+5. I'm a rare case, if not one of the first in Atlantic Canada, as I am using the Zip r6.6 for a remodel.

My system is Cape Cod woodsiding, 5/4" strapping rain-screen, Zip r6.6 + 2x6 r20 fiberglass or r22 rockwool (when replacing is required) and 6 mil poly (sealed where new drywall was placed).

The original was pine siding, 5lbs felt paper, r20 fiberglass, and 6 mil poly. Energy audit came in around 9 ach... (no sheathing at all would do that!)

The original was was just to use 7/16 OSB with Tyvek with no exterior foam.

I'm pretty confident this system will work and it will do just fine with minimal issues. I ran into this spotlight when I started looking for a solution to multiple cantilevers the house has. My current plan is to spray 1" foam sealant (Dow froth pak) on the underside of the subfloor between the joists and fill with rockwool r22 and cover over with Zip r6.6. Any issues with this idea? Should I just omit the foam sealant?

I'm glad to see this Canadian perspective. I am putting an addition on a house in Ottawa (Zone 6) this spring, and the Architect has spec'ed the same assembly that you have described here. I have gotten assurances that this assembly has a proven record in this climate.

My understanding is that the key to making it work is very careful and prudent air sealing. Getting this right begins as early as the framing of the mudsill, where its imperative to get the air barrier in place under the sill, then around the rim joist, then under the wall framing on the first floor, then over the wall framing in the basement, then finally sealed together with the with the 6 mil poly just behind the drywall.

User 7004347,

First of all, can you tell us your name? (I'm Martin.)

Q. "My current plan is to spray 1 inch foam sealant (Dow Froth Pak) on the underside of the subfloor between the joists and fill with rockwool (R-22) and cover over with Zip R-6.6. Any issues with this idea?"

A. No. For more ideas on this type of floor assembly, see "How to Insulate a Cold Floor."

Q. "Should I just omit the foam sealant?"

A. You can if you want, although spray foam insulation is an excellent air barrier. No matter what approach you take, you need to pay close attention to air sealing.

Hi Martin,

Sorry my name is Kent, and thank you for your responses. I hear what you are saying with spray foam insulation vice spray sealant. For whatever reason in my area I am unable to get the small pack style foam insulation, they only sell sealant. The actual spray insulation contractors in my area have about a month wait... I'm still getting the same R-value of 5.5 per inch, so I didn't really see any difference in products.

Log in or become a member to post a comment.

Sign up Log in