Image Credit: John Straube

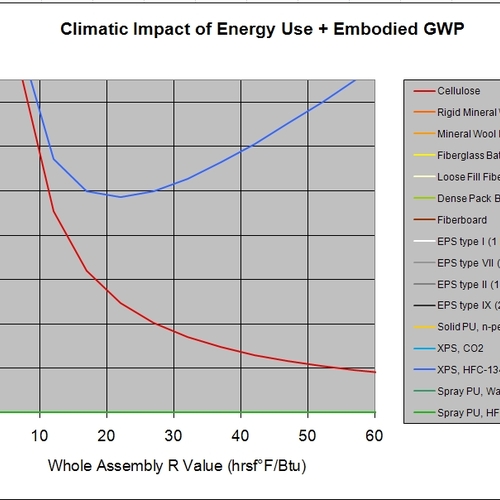

Image Credit: John Straube Twelve inches of sub-slab XPS was used in this Passive House in New York state. It will take several hundred years of energy savings to pay back the global warming potential of that insulation.

Image Credit: Jordan Dentz, The Levy Partnership, Inc.

I’ve been pretty vocal about a big problem with some of our most common insulation materials: that they are made using blowing agents that are highly potent greenhouse gases.

All extruded polystyrene (XPS) and most closed-cell spray polyurethane foams (SPF) are made with HFC (hydrofluorocarbon) blowing agents that have global warming potentials (GWPs) many hundreds of times greater than that of carbon dioxide. (My apologies for contaminating this column with so many acronyms!)

Insulation: good news, bad news

Insulation materials help our homes save energy and, in so doing, they reduce the combustion of fossil fuels and the release of greenhouse gases.

But if the insulation material itself is made with a very-high-GWP blowing agent that may ultimately escape from the insulation, adding a lot of insulation may actually be a bad thing from the standpoint of mitigating climate change. All that was spelled out in my blog post two years ago, “Avoiding the Global Warming Impact of Insulation” and, in greater detail, in the EBN feature article on the same topic.

OK for ozone, bad for climate

With XPS, the blowing agent HFC-134a has a GWP of 1,430, meaning that it’s 1,430 times as potent as carbon dioxide (which is defined as having a GWP of 1). Nearly all closed-cell SPF is made with the blowing agent HFC-245fa, which has a GWP of 1,030.

Relative to global warming, these blowing agents aren’t as bad as the CFCs that were used originally, but they are as bad as the HCFCs (hydrochlorocfluorcarbons) that were adopted as second-generation blowing agents. (Both HFCs and HFOs are considered totally safe for the ozone, which is why CFCs and HCFCs have been phased out.)

Blowing agents: the next generation

Anyway, given all this, I’ve been closely following the developments by industry in coming up with alternatives that are neither ozone depleters nor significant greenhouse gases.

Two years ago, it appeared that the leading candidates were HFOs (hydrofluoroolefins), and Honeywell announced the development of such a product in 2011. And indeed, it was just announced last week that Whirlpool, the nation’s largest appliance manufacturer (with such brands as Maytag, Amana, Jenn-Air, and KitchenAid, along with Whirlpool), was switching to a new HFO blowing agent for the polyurethane insulation in all of its refrigerators.

Whirlpool will be using the new Solstice Liquid Blowing Agent made by Honeywell, one of the nation’s three producers of blowing agents (along with DuPont and Arkema). Solstice HFO has zero ozone depletion potential and a GWP of just 4.7 to 7.0—similar to that of the various hydrocarbon blowing agents used in expanded polystyrene and polyisocyanurate — and insignificant relative to global warming.

Efficiency boost an added bonus

Further, Solstice HFO will boost the R-value of the insulation material slightly. Compared with HFC-245fa, this HFO produces insulation with 2% higher R-value, and compared with hydrocarbon blowing agents it offers an 8% to 10% improvement, according to Honeywell.

While the change is exciting, it is not immediate. The HFO has just received its approvals from the government, and it will take a while to ramp up production and convert refrigerator factories to the new foam. Whirlpool expects to begin incorporating the new blowing agents into its refrigerators in late 2013.

Spray-foam manufacturers slower to adopt HFOs

But what about the closed-cell SPF insulation that is commonly used to insulate buildings?

SPF manufacturers will probably be replacing the HFC-245fa with HFO … but it’s unclear exactly when that will happen. Rick Duncan, the technical director at the Spray Polyurethane Foam Alliance (SPFA), the trade association serving the SPF industry, told me that some SPF manufacturers (“system houses”) are conducting field trials with the new HFO blowing agents, but not all of them. (At least one manufacturer, Icynene, also makes a water-blown, medium-density foam, MD-R-200, which insulates to R-5.2 per inch and is referred to as both an open-cell and closed-cell product on the Icynene website; most other water-blown SPF products are believed to have been discontinued.)

Unlike in 2003 when federal regulations mandated a switch from HCFC to HFC blowing agents due to ozone depletion concerns, there are no similar regulations requiring a switch from HFCs to HFOs.

It’s up to us

And the conversion takes time and is expensive — about one year and at least $100,000, says Duncan. With the building industry still in an economic slump, producers aren’t looking to spend a lot of additional money on product development.

Duncan believes, however, that when a new life-cycle assessment (LCA) report on SPF comes out that SPFA is now finalizing, customers will begin asking for lower-GWP foam and manufacturers will respond by producing it. From an environmental standpoint, open-cell SPF (which doesn’t include HFC blowing agents) has just 1/20th the global warming impact of closed-cell SPF.

Less action in the XPS camp

I was not able to get as much information from the extruded polystyrene industry about when the HFC-134a might be replaced with a lower-GWP blowing agent and whether there is a gaseous form of HFO that could work for that industry. (While a liquid blowing agent is used in producing SPF, a gaseous blowing agent is required for XPS.)

Jan McKinnon, the senior communications manager at Dow Building Solutions (manufacturer of Dow Styrofoam XPS), says that the company is looking for ways to reduce its greenhouse gas emissions. “Since the launch of our new formulation in 2010 [converting from HCFC-142b to HFC-134a], we continue to look at lowering our blowing agent global warming potential, and we have an active process in place to reduce it by 15%,” she told me. She said that they are actively evaluating alternative blowing agents for XPS, “but most of these technologies are still in their infancy.”

Not a great time to invest in products

Both the SPF and XPS industries have already gone through two major transitions: from CFC to HCFC blowing agents and then from HCFC to HFC blowing agents.

With a weak building economy and depressed sales of building materials, enthusiasm for a third major conversion has been limited. But I believe that there will be growing demand to produce products with as little impact on global climate change as possible — and if this year’s heat and drought continue, that demand may well grow.

Let’s hope so.

Alex is founder of BuildingGreen, Inc. and executive editor of Environmental Building News. To keep up with Alex’s latest articles and musings, you can sign up for his Twitter feed.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

13 Comments

Dow

Jan McKinnon at Dow must not be familiar with an apparently little-known company called "Dow Building Solutions UK" and the other European Dow companies that use CO2 as the blowing agent for XPS...GWP of 5 according to Dow.

http://building.dow.com/eu/gbr/en/products/styrofoam/about/envirostandards.htm

Dow in Europe

Yes, Dow (and everybody else making XPS in Europe) have shifted to non-HFC blowing agents--I thought they were hydrocarbon blowing agents, but they could be CO2. Dow in the U.S. claims that our market wouldn't accept a product that didn't achieve R-5 per inch. (I think the European XPS only achieves R-4 per inch.) I've tried to argue with Dow that maybe--just maybe--American builders could be convinced to use 2-1/2 inches instead of 2 inches to achieve comparable performance.

Dow in Europe

Yes, R-4.0/inch to R-4.4/inch with the CO2 blowing agent, depending on the exact product and board thickness.

http://building.dow.com/eu/gbr/en/products/styrofoam/floormate.htm

Just say no, or almost so

We can build high performing resilient buildings without foam, or nearly so. At Subslab it is difficult to substitute, but everywhere else, not hard - and one can even get a more resilient and robust building in the process. Win-win-win. We just need to kick the foam habit.

Foam is here to stay. No

Foam is here to stay. No matter how one or two feel. I prefer to stay neutral myself. The tech is improving every year.

response to AJ builder

Agreed.. And glad to see it improving. Yet if we can build robustly, resiliently and more sustainably, largely without foam - seems like a rational direction would be to limit its use to when only absolutely necessary. Oil is here to stay too......until it's not....

Polymers do not have to come

Polymers do not have to come from oil or even fossil fuel. Chemistry today and tomorrow is rapidly advancing.

This is not the industrial century. Today we are in the nano decade and moving into the cyber infinite everywhere icloud end of natural resource over-use time.

Since the first laser diode and microprocessor we have been inventing an unlimited plethora of tech which is rapidly filling and over-filling the works with boundless future resources that we now tap into just in time capitalistically.

And of course part of the drive for all this good happening is the constant whine of all, yaa know, climate change, CO2, and dead bats and bees.

IPAs for all the builders.... bartender...

Water-Blown Closed-Cell

Please note that the Icynene Water-Blown Closed-Cell spray foam is MD-R-210, not MD-R-200. The

"R" refers to 7% recycled content. It is R-5.8/inch.

Bob

MD-R-210

Our company sprays open & closed cell foam. With water-based closed cell foam, you have to make sure the substrate is warm enough in winter. In new construction this means heating the envelope up to get the first coat down. If you don't do this, you can get closed cell peeling back or shrinking. This is why some contractors go with a "winter blend" for closed cell. All of the winter blends, however, that I am aware of, use HFC's for blowing agents.

No one product is best for all situations. Closed cell is pretty good in a lot of them.

Bob

Robert, is MD-R-210 the best

Robert, is MD-R-210 the best "use in all locations" spray foam? Do you spray?

Thank you Bob

Spray Foam and Health Issues

The largest part of this discussion which is critically missed, "HEALTH."

Do any of you readers understand the health ramnifications of using spray foam insulation?

Do you understand what these products will do to you, your family and others you recommend it to? Well, I do and it's not pretty. Try keywording some of your own health questions. You may be shocked to find there are very, very few answers. That is unless you know where to look. Here's a couple links for you:

http://blogs.cdc.gov/niosh-science-blog/2012/03/sprayfoam/ and http://www.epa.gov/dfe/pubs/projects/spf/epa_niosh_osha_spfa_confernce_presentation_february_2011.pdf

All to often builders and industry experts make a claim to fame when something new is introduced to make our lives safer and more economical without doing the research first. I will be the first to admit, I did this to. However, I did do the research on spray foam insulation and came up with nothing but the positives of spray foam (aka SPF). The real issue with these SPF products (open and closed cell) is any keyword you use online dating back to 1997 to current is industry promoted.

HGTV and many other DIY channels are promoting Spray Polyurethane Foam Insulation without publishing any research on the health implications. Holmes on Holmes appears to be in the room as the guys are spraying the foam. Bob Villa and Norm of This Old House promote these products now and in years past. As a matter of fact, my SPF applicator was the same company which recently sprayed a home for This Old House in a Rhode Island home. This company is one of the largest in the northeast and sprayed my home with off-ratio foam. (ie; closed and open cell name brand foams)

What would you say if I told you part A-side of SPF was modified Formaldehyde changed chemically to make (MDI) methylene diphenylene diisocyanate. Well, it is! This is the A-side of all SPF manufacturers foam insulation. Many have Formaldehyde in the B-side as well. In CT Formaldehyde containing spray foam is legal as long as it is Urethane or Styrene foam and not (UFFI).

See: CGS Sec. 29-277. Urea-formaldehyde insulation: Definition; prohibition concerning use; penalty. (a) Urea-formaldehyde (UF) foamed-in-place insulation, also referred to as formaldehyde-based insulation, means any cellular plastic thermal material which contains as a component chemical formaldehyde, formaldehyde polymers, formaldehyde derivatives and any other chemical from which formaldehyde can be released, but does not mean urethane foam insulation or styrene foam insulation.

(b) Urea-formaldehyde foamed-in-place insulation shall not be installed in any building or structure on or after June 1, 1981.

(c) Any person who violates any provision of this section shall be fined not more than five hundred dollars for the first offense and for each subsequent offense shall be fined not more than one thousand dollars.

(P.A. 81-250, S. 1-4.)

Are you aware that if you are in a home when these products are installed without respiratory protection the chemicals can cause permanent lung damage and death?

"Persons developing sensitivity to isocyanates may have dangerous systemic reactions to extremely small exposures, including respiratory failure. MDI should not be heated or sprayed except with strict engineering controls and personal protective equipment."

See: http://www.thefullwiki.org/Methylene_diphenyl_diisocyanate

Are you aware that the medical community is studying humans who have these products installed within their homes? Are you aware the medical community is studying the men who apply these products? Dr. Redlich of Yale University is the most known doctor researching the effects of SPF and humans.

Are you aware our own government is just recently taking notice and most recently are studying the health implications of these products.

Do you think the government is studying these products just because they want to help us. No!

People are complaining and are injured. ie; health and property damage. Many believe SPF is the next Chinese Drywall and the next (UFFI) Urea-Formaldehyde Foam Insulation which is banned in many states.

I know first hand because my contractor contaminated my house with 3 different spray foams and they all failed.

My reason for posting is to help you. Every SPF company I have spoken to will not tell the truth and/or are afraid to. Reality is this... you complain, you are ISOLATED.

Ask your State Department of Public Health and or Building Officials for information relating to health and SPF. Do not feel shocked when you learn as I did they do not know how to handle issues relating to spray foam insulation.

Please do your homework first guy's. There is a lot more to building than energy conservation. There is responsible building to.

I'll be the first to tell you, these products do not belong around people or children with Asthma!! If you still want to specify or use these products, call the manufacturer and verify your applicators credentials first. Do not trust the salesman! Call the manufacturers corporate office for credential verification. Make sure you get "EVERYTHING IN WRITING" from the manufacturer and the installer. Do not believe the verbal claim's because when you have a failure (odor, shrinking, cracking, etc.) and you do not take the proper steps, this will easily become the most expensive insulation you ever gambled on. One last piece of mind for you.....your homeowners policy will not cover you for any SPF failures. You better verify your contractor is insured for a minimum $1M policy plus an umbrella policy endorsement for at least $5M. Do not be afraid to ask to be named as an additional insured. The future is only going to bring numerous lawsuits as more and more people have these products installed in their homes and complaints surface. Builders, Architects, Designers and Applicators are not immune from the claims.

I hope my experience helps you all.

My home in the news...

http://landing.newsinc.com/shared/video.html?freewheel=91060&sitesection=WTIC_hom_non_fro&VID=23903508

“[Deleted]”

Log in or create an account to post a comment.

Sign up Log in