Image Credit: Martin Holladay

This blog, a report on my three-day visit to Passivhaus construction sites and the Passive House Northwest conference in Washington state, picks up where last week’s blog left off.

After leaving the North residence job site, we drove to the Freas house, another construction site in Olympia. The steep site has a dramatic view of Budd Inlet, an arm of Puget Sound, to the west. (Author’s postscript: On August 15, 2013, the New York Times published an article on the Freas house: “The Passive House: Sealed for Freshness.”)

A modern house with a great view

A design/build company from Olympia, The Artisans Group, is building a single-family Passivhaus on the site. Designed by architect Tessa Smith, the house conforms to a severely modern aesthetic: it’s a flat-roofed rectangle.

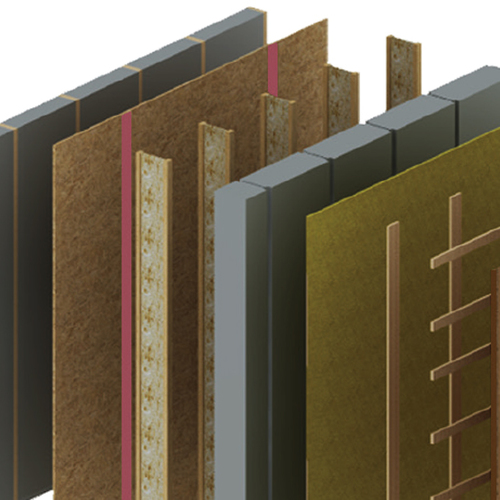

Smith is proud to report that (with the possible exception of some gaskets here and there) it’s a no-foam house. The floors, walls, and ceiling are all insulated with blown-in fiberglass. After their insulation contractor had trouble achieving required densities while insulating sheathed walls at the North residence, Smith resolved to change their approach. “We’re not blowing any cavities blind anymore,” she said. “We’re blowing through netting.”

Here’s a summary of the Freas house specs:

- Area: 1,350 s.f. (“treated floor area” = 1,137 s.f.)

- Foundation: unconditioned uninsulated crawl space

- Wall framing: Double 2×4 walls

- Air barrier: OSB with taped seams on interior side of insulation

- Wall sheathing: Vapor-permeable fiberboard

- Floor insulation: 24 in. blown-in fiberglass (R-91)

- Wall insulation: 14. in. blown-in fiberglass (R-55)

- Ceiling insulation: 24 in. blown-in fiberglass (R-91)

- Windows: Triple-glazed Pazen EnerSign; SHGC = 0.54 (glazing only)

- Mechanical ventilation: Zehnder HRV

- Domestic hot water: Gas-fired Navien instantaneous heater

- Design heat load: 7,000 BTU/H

- Space heat: hydronic radiator circulating water from domestic water heater

- Air leakage rate: 0.49 ach50

To learn more about…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

20 Comments

Joists in Picture

It appears that one of the joists in the picture was cut in half for the 3" ducts. I hope the sheathing is not supporting a floor.

Response to Andrew Quniter

Andrew,

The answer to your question can be found in the caption to Image 3. The 2x6s are not structural. Here's what the caption says:

"Here's a great idea: installing a layer of 'false ceiling framing' to accommodate wiring and ductwork. At the Freas house, the builders installed a layer of OSB on the underside of the open-web ceiling trusses to establish an air barrier at the ceiling. The OSB seams were carefully sealed with Siga tape from Switzerland. Then a suspended ceiling was installed — 2x6 framing hanging on small Simpson clips — so that electricians and HVAC contractors don't disturb the air barrier."

A positive result reached: Local beer tests well!

Martin,

I'm glad the beer went down easily. As I recall, that was one of the initial goals of the visit: "Sample some finely crafted beers from the Pacific Northwest". And... Since you're here... we might as well see some super insulated construction!

I'm happy to be reminded that there is a point to making all these good buildings: Healthy places to meet, talk and enjoy the creature comforts of life.

All the best from Passive House Northwest. http://www.phnw.org

Albert Rooks, Secretary

Oy, those R-90 envelope

Oy, those R-90 envelope assemblies are killer.

Good to see more panelization here in the Northwest. It’s pretty much standard practice in the EU now, and with the increased utilization of gaskets hopefully something we’ll see more of.

Milos Jovanovic is with Root Design Build.

Any ideas as to how long til Agepan (or cross laminated timber) are manufactured here, and not just imported?

Response to Mike Eliason

Mike,

In Seattle and Olympia, is "killer" good or is "killer" bad?

Thanks for providing the name of Milos's firm.

Concerning your question, "How long til Agepan (or cross laminated timber) are manufactured here?", I imagine that a production facility would want to see a potential market of more than 2 or 3 dozen Passivhaus buildings a year.

in this instance, killer =

in this instance, killer = bad. even with the lack of solar gain mentioned in conference, that seems really high for our mild climate. i'm guessing partially due to low SHGC of the pazen (i consider 52% too low, especially for our region)

yes, i would imagine more than 20 or 30 PH projects a year - but it has useful applications in non-PH buildings as well.

CLT plant is developing in Montana

Martin and Mike,

Montana Sustainable: http://www.smartwoods.com, has been developing the US's first Cross Laminated Timber plant in Whitefish Montana. The development has been going on for a while and they have been partnering with some very solid German and Austrian companies.

The exciting news is that they have finalized North America's first commercial CLT project. I spoke to Pat Clark last week and the final numbers were due today. It will be a very interesting project. The CLT Panels will be built in Austria by the partner, containerized, and erected by crane in Whitefish this summer. The project is a very nice multistory on an infill lot.

CLT construction means that, the panels are all set in place by crane in a few days. The air sealing is done on the panels when the entire building is up, and then the exterior is wrapped with continuous insulation. For this building, they've chosen to tape for airsealing, and then wrap with Roxul. It appears to me to be an excellent diffusion open wall. There is not a layer that will not pass some amount of water vapor, so it should live a long and healthy life (in 100's of years?) if reasonably maintained.

If it's interesting to anyone, I wrote a blog entry of a CLT building under construction that I walked. It's in 3 parts at: http://www.smallplanetworkshop.com/architectural-travel-blog/ I apologize in advance, the pictures load very slowly due to file size. The bio mass plant in the basement was exceptionally impressive.

The opportunities for CLT's in the US are good. As engineering improves, these structures can grow to significant multistory structures like you can see in the blog entry. They essentially compete with concrete and steel.

I attend Sunday Mass regularly at "The Church of the Sacred Wood Fibre"... Meaning: I like wood. Anytime I see wood effectively competing with concrete in any structure, I think it's a very positive development.

PHPP

I've wondered about this. Did Dylan determine this by experience or is this an official disclaimer from PHI?

It would be interesting to understand why this is the case if it is in fact true. Other than the 'ventilation' worksheet doesn't the PHPP provide a thorough static model of the heat loss/ gains physics that happen for any structure?

I suspect when uncontrolled air exfiltration becomes high enough some of the mathematical assumptions must change. As I have attempted to model my own home in PHPP (ACH50 3.5, no mechanical ventilation and without a well defined thermal envelope) I get annual heat energy consumption in the PHPP significantly greater than my actual usage. (Though the model may need another round of checking the accuracy of the inputs.)

Agepan information

Albert, can you give us an R-value for the Agepan, and confirm that it's fully structural for wind bracing? Hoping to see some alternatives for petrochemical SIS coming along, even if it'll take a while to become generally available.

Passivhaus, but Green?

GAS!?! fired water heater instead of Solar hot water? Oy, Still don't totally understand the fiberglass preference....

clt

I met the smartwood guys at the pdx phnw conference. The thought of importing CLT seems to erase the merits of using it. Looking forward to the things going on in BC despite weyerhausers disinterest in it. Do you have embodied energy for agepan? TU Muenchen has a report that shows holzfaser graue energie (embodied energy) at about the same as eps low density. Is the manufacturing process that intense?

j chesnut

You could be dealing with the shadow concept "infiltration heat recovery".

Agepan values

James,

The Agepan THD 230 is R-2.84/inch. The 60mm (2-3/8") thick boards that I'm going to work with = R6.81 at 60mm. They will not carry the shear loads. We are going to start with these for diffusion open wall assemblies that already have a layer of OSB or Plywood that will pick up shear.

I see two initial simple assemblies:

1: Double stud/larsen truss with OSB/Ply interior and Agepan exterior. The function of the Agepan will be the exterior skin: Hold the dense pack cellulose in without deforming while adding to the overall R value of the wall. The Assembly is diffusion open from the OSB out with the final layer of Agepan at 18 perms.

2: I'm curious how it will fit on our Energy Star (or other homes): The large home penalty is to wrap an R5 exterior layer around the house. The "go to" product is of course foam. I'd like to see a house or two done with this material. I think (read: hope) that we find unexpected advantages along the way other than the obvious: that it's a wood product & that it's vapor permeable. It holds fasteners, but we still have to learn what kind and how well. It cuts easily and has no vocs or harmful off gassing. No more pink jobsites? You never really know what you'll find until you get into it.

Since the material is woodfirbre & wax... all bound together by PU... 60mm thick and on a tongue a groove board, house wraps are redundant as the material is "rain shedding" (they say). Exterior seems can be taped with the right tape: Siga Wigluv + Dockskin primer, and then a ventilated rain screen is added.

If some of the insulation applications of foam can be picked up by wood products, then I'm in. Obviously we all see a significant increase in insulation values for all basic assemblies coming down the road. My concern is that as an industry, if we begin to wrap or spray everything with foam, then my goodness... That's going to be a lot of foam.

Here in Olympia Wa, we have a healthy and growing deconstruction and building material recycling opportunity with the local Habitat for Humanity Re-Store. The framing material is already hard to deal with. Once the standard practice for cavity insulation and air sealing is a spray foam, I think it's safe to say that that material is now consigned to a single use lifespan. Once the lifespan is done, then into the landfill its goes... Foam and all.

The point of developing this kind of material in the US is looking at the whole product life cycle: Raw material collection & production, product installation, and then finally a recycling or composting option at the end of the life cycle. If other cultures have developed good insulation boards from woodfibre, then we can do it here in the US and Canada also.

I'll be visiting the Agepan factory in Germany, as well as building sites in late May. If you want to stay up with what I learn, feel free to RSS the "Architectural Travel Blog", or perhaps better, subscribe to the "Newsletter" at http://www.smallplanetworkshop.com.

EE And Import

Mike,

Yes... Certainly importing the CLT's erases the expected benefits. But... You have to start somewhere. There are investors, but both the theory and market must be proven before one can invest in the production plant.

To set up a CLT plant is no small thing. The two large functions are: 1, Laminating the panels with a very large press. (=$$). 2, cutting the panels.(=$$$) To make a wood CLT plant really competitive the machining is done by a large CNC (Hundegger or others). The idea is that once a panel is in the machining bay, the CNC cutting center is feed cutting instruction from the CLT Plants computer system. These cutting plans were developed as the project was modeled.

We do the same thing in the cabinet industry regularly. There are any number of CNC routers in shops that will take a 4x8 sheet of material and machine it into final parts in minutes. A CLT Plant "cutting bay" is the same thing... with much larger panels.

Due to the equipment costs, you have to walk a while before you run.

ME: "Do you have embodied energy for agepan? TU Muenchen has a report that shows holzfaser graue energie (embodied energy) at about the same as eps low density. Is the manufacturing process that intense?"

I have to say that that comes as a surprise to me. Sadly all I can say at this point is : "dunno". I don't have any EE experience yet, so I don't know how to make a comparison. It's now on the list...

infiltration heat recovery

Doug, I know how this works in my house.

Just works during the wrong season ; )

German OSB?

Are the Germans using OSB?

Euro OSB

Matthew,

Yes. All of the German countries use OSB in (it appears to me) similar proportions to plywood as the US. Perhaps more OSB.

The Euro OSB is different in the following ways: 1, It's very smooth compared to US OSB. It cuts, feels and works closely to our plywood. I guess that's great for every application except when your sliding off a roof.... 2, it is formaldehyde free as is most all of the sheet goods these days. The spec sheets go as far a as rating it "fire safe". That's is not that it won't burn, but rates that it's contents are "safe to burn" for heat without causing health issues.

Bio mass heating is a big deal over there, so having "safe" sheet goods removes many health issues: manufacturing health, application health, recycle/compost or for fuel health. I've got to say... I'm trying not to be a total "euro nut", but what I see is impressive. it's hard to not respect and feel that some of these products methods could "fit" over here.

Not sure if that helped or hindered the point of your question...

ACH50 and heat loss

j chesnut,

I think you are on to something with your inability to replicate your actual energy use with a heat loss program. Most energy geeks will be the first to admit a blower door test at 50 pascals does not represent normal conditions or typical leakage patterns for a given building. Far better would be tracer gas I believe, but that is getting quite scientific. We all know about the stack effect and how it works with common wisdom for air sealing saying, seal the high and low leaks first for the best efficiency gain. If you do this. many of the leakage points in the home like doors and windows are near the neutral pressure plane so on still days your infiltration heat loss could be far lower than a blower door test might indicate.

I spent 2 days in our attic air sealing before adding insulation and I also sealed the rim joist area in the basement. The attic insulation was upgraded to R-100 and the rim joist to R-20, R-10 Thermax was added to the interior basement walls. A new 95% furnace was installed and our gas usage for heating dropped from 1050 therms to 600 therms annually. The comfort was much improved and the energy savings seem greater than the sum of the parts would indicate, the ach50 for the house after air sealing is 3.14 or 1590 cfm50. The Btu/sf/hdd is 2.4, normal hdd is 7,876, the walls are 2x4 with fiberglass and 1" Styrofoam exterior sheathing, total sf is 3,328.

OSB

Thanks Albert, I just wondered about the OSB usage over there, I am sure it is not the same as ours, and ours is definitely NOT good for burning. Lots of formaldehyde in our stuff, that's why it stinks. If OSB was truly made from trash trees and recycling, then I would be a huge advocate. I know the truth is that they cut all of the Old Growth, planted plantations of same species, only so they can mow it down regularly and make panels and fiber boards. That is NOT sustainability..

Why Fiberglass

I do not understand why fiberglass is used instead of cellulose. It performs better, is less expensive and is a much 'Greener' product. It would be interested if they did some cellulose insulation and compare it to the fiberglass buildings. Also do not agree with the non staggered studs.

Log in or become a member to post a comment.

Sign up Log in