Image Credit: Images #1 and #2: BuildingNewb

An energy audit on BuildingNewb’s upstate New York home has prompted a recommendation that he insulate the rafter bays with dense-packed cellulose, transforming what is now a ventilated attic into conditioned space.

The HVAC equipment that’s already in the attic would then be located in a conditioned space, Newb writes in a post at GBA’s Q&A forum. The contractor has suggested that existing vents at the ridge and soffit be maintained, but apparently doesn’t see the need for any ventilation space directly beneath the roof deck, which is completely covered on top with Grace Ice & Water Shield, a peel-and-stick waterproofing membrane.

“The contractor told me that when cellulose is dense packed to the proper density, air and water vapor shouldn’t be able to easily get through it from the interior,” Newb says. “In the event any moisture does get into the cellulose, it will disperse throughout the material and find its way to the openings at the soffit or ridge rather than trying to diffuse through the wood which obviously has a vapor impermeable membrane on the other side.”

Newb says that air-sealing the attic floor looks like it would be too complicated, in part because of the three cathedral ceilings that terminate at the attic.

His contractor’s approach should yield R-35 of insulation between the 2×10 rafters, and keep the underside of the roof deck warm enough (the contractor claims) to prevent any water vapor that reaches it from condensing. Spray foam insulation is off the table due to potential health concerns.

If Newb chose not to insulate the rafter bays and live with the leaky attic floor, he says he’d upgrade the R-4 flex ducts for his heating and cooling runs to R-8.

Is the plan offered by Newb’s…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

3 Comments

Un-vented Cellulose roof

10 years ago when I knew even less than I do now an Insulation sub convinced me that dense packing the 2x12 rafter bays of an attic full of duct work and air handlers was the way to go. There were/are no ridge or soffit vents. because the house has a slate roof the insulation sub said venting was not need.

The house is in Rye NY, about 25 miles outside of NYC

So we went ahead with the work, almost immediately the owner said the house was more comfortable and less drafty and her utility bills dropped a noticeable amount over the following year.

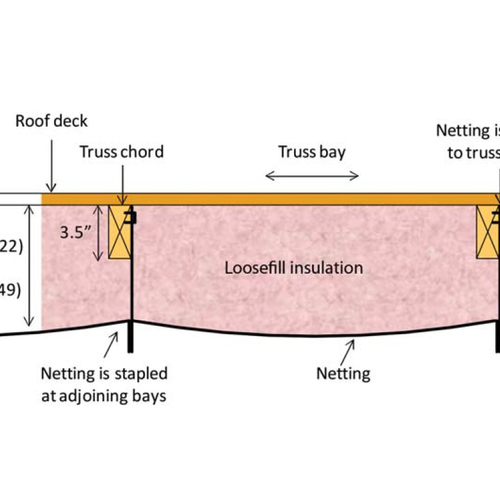

As time went on and I became aware of dew points & that vented roofs were to control condensation and prevent rotted roof sheathing I’ve made it a habit to stop by this house once or twice a year and stick my hand up thru a seam in the cellulose mesh, thru the cellulose and up to the underside of the sheathing. I’ve done this in at least a dozen places over the years, summer, winter, fall and spring and the cellulose and the underside of the sheathing are always dry as a bone.

Now if we had sheet rocked over the cellulose this might be a different story and I might have had a moisture problem, but I figure with only the cellulose and the mesh to hold it in place it is a vapor open roof assembly that is performing very well.

Response to Judson Aley

Judson,

Thanks for sharing your experience.

GBA recommends that readers only install cellulose between rafters if either (a) there is a ventilation channel between the top of the insulation layer and the underside of the roof sheathing, or (b) there is an adequately thick layer of rigid foam above the roof sheathing.

That doesn't mean, of course, that everyone who ignores our advice and installs dense-packed cellulose without a ventilation channel under the sheathing will end up with roof rot. It simply means that the approach is risky.

Some roofs (like the one you describe) may do well without the ventilation channels. Others (perhaps with air barrier defects or dense-packing defects) will fail.

GBA promotes insulation methods that are robust, not risky. That said, every homeowner has a different appetite for risk.

Shading factors matter. @Judson Aley

Slate roofs are at least partially vented on the exterior side of the roof decking (unless covered by an impermeable layer rather than asphalted felt.) Even a little bit of sunshine can improve drying rates by quite a bit. North facing pitches or sections of roof shaded heavily by trees/hills/buildings will usually have measuarably higher moisture content than south facing pitches in full sun. So the orientation and shading factor of pitch with the hand-feel test matter.

Rather than poking big hole in the mesh & insulation with a hand, use a 2-pronged moisture content meter, and measure the moisture content of the roof deck at several locations, making notes of the moisture content & date. The peak moisture content of roof decks with a class-III vapor retarder on the interior (latex paint on sheet rock) will usually be in late winter. In this case since there is no vapor retarder it may be shortly after mid-winter, but taking 2-3 measurements between Valentines Day and Tax Day would give you a better idea of the moisture content as temperatures rise to mold-growth conditions.

To poke it through a foot of insulation you'll need to make up extenders for the probe prongs, but that's not a difficult project:

https://www.greenbuildingadvisor.com/sites/default/files/Peter%20Yost%20moisture%20meter%202.jpg

Insulating the prong extenders with heat shrink tubing would be necessary for avoiding measurement error related to the moisture content of cellulose in direct contact with the extenders.

Log in or become a member to post a comment.

Sign up Log in