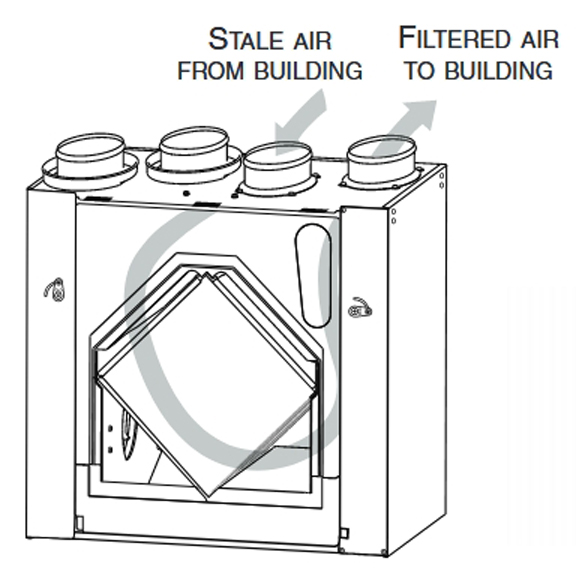

Image Credit: Image #1: Venmar

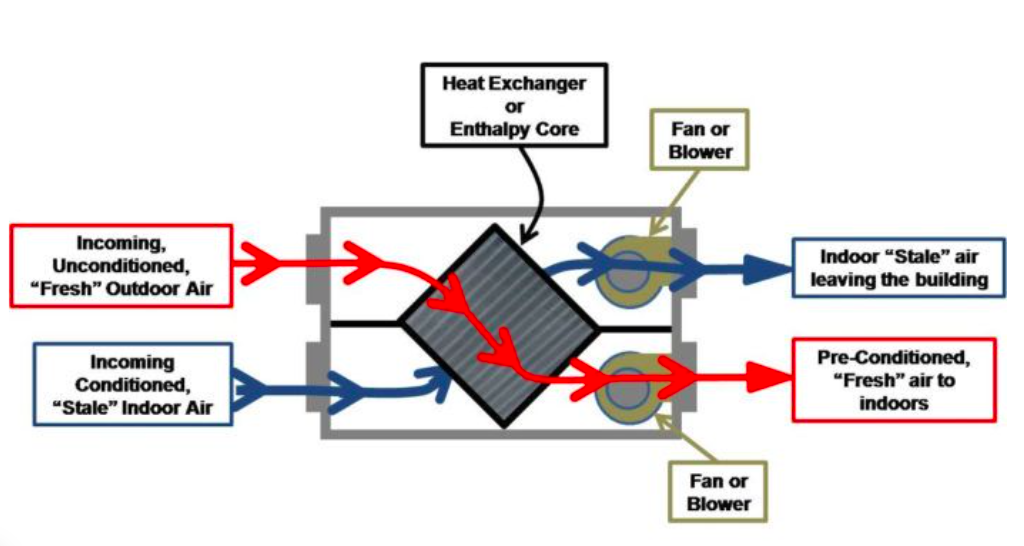

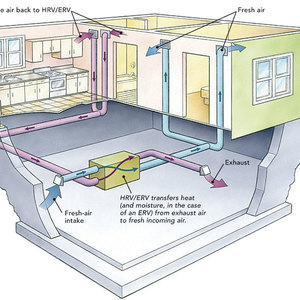

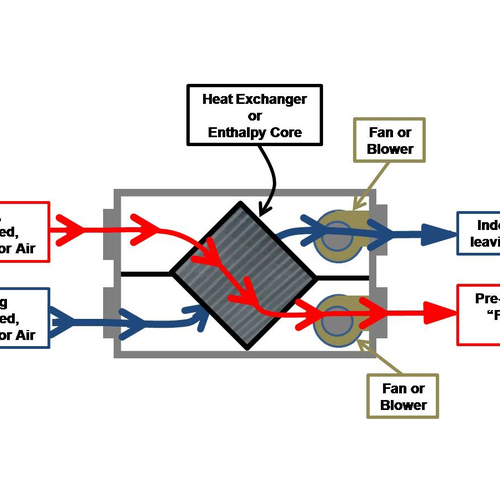

Manufacturers of heat-recovery ventilators (HRVs) and energy-recovery ventilators (ERVs) know that HRV or ERV cores can get clogged with ice in cold temperatures. During the winter, this type of appliance brings cold outdoor air in close proximity to a stream of humid indoor air. If the outgoing air is humid enough, and the incoming air is cold enough, the moisture in the exhaust air stream can turn to ice.

How cold does it have to be for these problems to occur? The answer depends on indoor moisture levels and the design of the HRV or ERV core. In general, HRV cores can ice up when outdoor temperatures drop to the low 20s, while ERV cores may not develop icing problems until outdoor temperatures drop to the low teens. That means that people who live in the warmer parts of Texas, Georgia, and Florida probably don’t have to worry about HRV defrost strategies.

Fortunately, the ice-up problem is easy to solve, and almost all HRV and ERV manufacturers offer solutions to this problem. There are five basic strategies:

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

32 Comments

Blast from the past?

"Your car has an automatic choke."

Maybe, if your car was manufactured before 1987 and was not fuel-injected. ;-)

Your car DOES have automatically adjusted ignition timing (unless it's a battery-only electric, or manufactured before 1930.)

Response to Dana Dorsett

Dana,

When I grew up, my parents had to pull out the manual choke lever on the family VW. Back then, VWs didn't yet have automatic chokes.

Then, a new invention appeared: the automatic choke! No need to pull out the knob to start the engine.

As you can see, I'm still amazed by the inventions of the 1960s. I can't be expected to keep up with developments in the 1980s... too recent...

Renewaire specs...

Just a small correction for Renewaire, Martin. Their units are not completely immune to frost build-up. Their specs say:

"Passive Frost Control

The ERV core shall perform without condensing or frosting under normal operating conditions (defined as outside temperatures above -10°F and inside relative humidity below 40%). Occasional more extreme conditions shall not affect the usual function, performance or durability of the core. No condensate drains will be allowed."

I interpret this to mean that extended conditions with outside air below -10F and/or indoor RH% above 40% could yield frost in the core. This certainly doesn't affect a whole lot of builders in North America...but it's best to have the full scoop.

That Renewaire spec seems like a self serving attempt to eliminate some competition as if having a drain is a bad thing. I believe that even though Vanee/Venmar ERVs have drains the instructions about hooking up the drains are specific to the HRV submodels which likely use the same cabinet as the ERVs.

Response to John Semmelhack

John,

I appreciate your comment. Thanks for quoting the Renewaire specs -- I hadn't seen that section.

I spent a lot of time trying to track down the facts on this story. On January 30, 2018, I had an extended phone conversation with Nick Agopian, the vice president of sales for Renewaire (now owned by Soler & Palau of Spain). Here's what Nick Agopian told me:

"These units have no potential for any condensation. ... The units don't require a drain pan. We shipped 25,000 units last year, maybe 27,000 units, and we’ve got 750,000 units in operation, and these units do not have one single drain pan. ... There are no climate restrictions. We have an installation in Point Barrow, Alaska, with no drain pan. In addition, the USGS was researching climate change in Antarctica, they were drilling into the ice, and they were using our units to ventilate tents in Antarctica for over a year, with temperatures as low as -117 degrees F, with no problems."

Our HVAC has quoted a Renewaire for our build in IECC zone 6 so this very point -- passive defrost -- got me digging around GBA and studies elsewhere.

Martin & John,

I posted on another thread a link to cold weather ERV research that was done up in Alaska in 2014 that included a Renewaire model, among others. That research is also linked here though I don't see it cited/referenced. Anyways, basically the findings don't fully support Nick's statements to you. [0] The report says that condensation WAS observed in the Renewaire ERV. Frost or freezing was not observed; OK, so that agrees with Nick's statements that their ERVs can run up in Alaska but condensation is water that could, nonetheless, freeze. Actually another one of my concerns with condensation in this scenario is mildew/mold. Or am I being paranoid? :)

Having said that, the test was done on one of their smaller ERVs, the EV130, and it has lower performance #'s than Renewaire's larger models, so maybe that introduces less than ideal variables?

[0] http://www.cchrc.org/energy-recovery-ventilators-ervs-cold-climates

Anticipation

Waiting all week for this article, Thanks Martin for the information, very informative.

So now can we look at them from an energy use for people in the colder zones?

Since that is why most of us are here, to save on energy, for the wallet or the planet.

The super efficient Zehnder needing pre-heat(either electric resistance or glycol loop) how does this compare to a efficient Broan/Venmar unit that recirculates.

I would think the Zehnder unit or Ultimate Air in colder regions is less energy efficient (needs pre-heat), so should really not be a choice for anyone needing a defrost cycle for any length of time.

I'm not smart enough to figure out if the Zehnder or Ultimate Air units make up for the pre-heat in there SRE numbers, I"m sure someone is, but those pre-heaters seem to use enough energy to make me doubtful that they are great choice's in colder climates.

Also what is the big deal about a condensate drain, this seems like a minor issue, again I would rather have an energy efficient unit, and just deal with the water. How much water can it be?

Dana, it is a little funny and dated.

Tents in antarctica

I am surprised to hear that the USGS tents are air-tight enough to need mechanical ventilation.

Interesting. I get a really

Interesting. I get a really uneasy feeling when a manufacturer tells you one thing verbally which is contradicted by their own published documentation. If they don't back it up in writing, the claim should be summarily ignored. So, if frost is a problem below -10F / -23C, and they have no frost protection strategy at all, what happens when it goes below that temperature? I don't want to find out at 2am one winter morning.

Zehnder's and UltimateAir's efficiency numbers would definitely not include the effects of preheating. All of the test points are at temperatures above which pre-heating would be required.

My mom's 1981 Honda Accord had a manual choke.

Location Of HRV Intake

In the 1980's we had problems with a frost layer on the hardware cloth for the fresh air intake. This was typically on the very coldest days and the frost would form a continuous layer preventing the intake of air through the hood. We lacked good HRV controls in those days so the homes were most likely over ventilated. It seems that HRV/ERV intakes would benefit from being placed on the sunny side of the house from an operational and efficiency standpoint. Could this intake have a non airtight solar enclosure to temper the air being brought into the house? Kind of following on the Earth tube theme but less involved. These hood vent screens also get clogged easily with cotton from trees and should be cleaned often. We need better fresh air intake hoods with a larger screen surface that is removable for easy cleaning. The photo of the frosty ducting makes me think a longer intake duct would temper the air somewhat to the HRV/ERV by using the inside air in the mechanical room as a buffer.

Doug,

Locating the intake in

Doug,

Locating the intake in the sun is only going to make a difference during the day, and when the sun is shining. During the part of the year when you'd really need it, it would be there less than a quarter of the time.

Remember that the frosty duct in the picture is not the intake air, it's the conditioned air. The intake duct is insulated, to prevent condensation and also for energy efficiency. If you use the indoor air to temper the incoming air, it also defeats the purpose of the HRV/ERV. The buffering you could get by routing the duct through conditioned air is achieved in a controlled manner using the recirculating techniques.

Response to Dave B (Comment #5)

Dave,

Q. "The super efficient Zehnder needing pre-heat (either electric resistance or glycol loop): How does this compare to an efficient Broan/Venmar unit that recirculates?"

A. John Semmelhack did an energy modeling exercise to compare the energy use of a Zehnder Comfo 250 to that of an Ultimate Air 200 DX in six different climates. In all six climates, the Zehnder used less energy. For more information, see Figure 3 at the bottom of the article on this page: Are HRVs Cost-Effective?

Needless to say, just because the Zehnder has the lowest operating cost, doesn't mean it's cost-effective. Its installation cost is so high than it may be hard to justify the incremental cost compared to a simpler ventilation system.

Q. "Also what is the big deal about a condensate drain?"

A. The need for a condensate drain is correlated with the need for a more robust defrost strategy. If an ERV doesn't need a drain pan or a condensate drain, that means that the design of the ERV core allows enough moisture to be transferred from one air stream to another to reduce or eliminate the possibility of frost formation.

A second reason to pay attention to this issue is that condensate drains are usually expensive to install, and in some homes -- where the mechanical room is far from a convenient DWV pipe -- almost impossible to install.

Responses to future questions may have to wait...

I'm getting ready to leave on vacation, so answers to further questions may have to await my return on April 16. Fortunately, the GBA community of experts will engage in a fruitful conversation and debate without me, to everyone's edification.

GBA blogger and longtime GBA friend Michael Maines has agreed to moderate the Q&A forum in my absence. (Thanks, Michael!)

During my vacation, new "Musings of an Energy Nerd" blogs will continue to appear, on schedule, every Friday.

Response to Martin

Thanks for the link Martin, I do recall reading that article before, although like everything there has been upgrades to new more efficient units.

Looking on the HVI site it seems that the newer Venmar ERV X24 are more efficient than the Zehnder ComfoAir200 ERV and Venmar uses recirculated air and not a pre-heater.

Not sure why Ultimate Air is not on the HVI site??

I personally do not like exhaust only systems, but I know they can work in some situations.

condensate pumps

Condensate pumps are a reasonable solution when there's no convenient way to directly plumb a drain. They do introduce a potential failure point, so they aren't ideal, but they work, and don't run enough to be a concern for energy use.

UltimateAir says they choose

UltimateAir says they choose not to list on HVI's database because there is a cost, and they don't see the value. They do have a certificate on their website by a third party testing lab, so you can do a comparison.

UltimateAir testing

Thanks Trevor

I looked at the third party testing and was surprised to see that it shows the watts usage at over 200.

The Venmar X24ERV shows max at 83watts.

That is more than double, or maybe I'm reading it wrong (there is a chance of that)

I do see SRE numbers that look better at different airflow's(cfm) and maybe this is where I'm getting confused on efficiency.????

An ECM fan can vary widely in

An ECM fan can vary widely in power draw, depending on flow and static pressure.

They have done their testing

They have done their testing at maximum airflow, and through a MERV 12 filter. The rep I spoke to suggested that the other brands test a lower filtration rate and that explains the power discrepancy. I have no idea if that's true. In the manual they have a power curve. At 84cfm it's 55W. Keep in mind that the fan power is accounted for in the SRE.

Testing

I would like to know what HVI tests with,you would think the filters that come with the units??? I guess some use MERV 6 filters,the only other option is usually a HEPA filter.

So just looking at ERV not HRV on the HVI site it seems the max rated SER @ 0

Venmar X24ERVE -84

Zehndar CA350ERV -78

Ultimate Air 200DX -83 third party testing

So does this mean the Venmar is the most efficient??

Regardless of the watts shown?

Defrost and More

So- I knew this article would be a good one.. for those of us heat exchanger super energy geeks! Here we go- (PS- this is jason morosko from Ultimateair... and i love the math relating to ventilation loads )

1. Condensate drain- No, we do not need one. It is purely in the design of heat transfer media of our machine. We use a rotary random matrix media and the surface area of the fibers is not sufficient to allow water to form and 'drip'. It is either carried to the opposite air stream in the vapor state- or it passes through. No drip. Unique to each manufacturers design... not ERV/HRV specific.

2. Defrost strategies-

a. So- if you do exhaust only, is that same amount of air coming into the house somewhere (A. yes)... and at what temperature (COLD). Did you run that number (cost to reheat X amount of air for how long at what temperature... I have..)? Compare this to just using electric heat. i have.

b. So- re-circulation- I ask.. well why did you put in mechanical ventilation for? I agree that 'most' of the time that the recir is happening.. no one knows or cares that you are not getting the fresh air (ACH) that you were promised (required to get for good IAQ)..(to Peter).. BUT if you are asking the real question- If i need X amount of ACH (air changes per hour) at a COLD outside temperature- what method is the 'most efficient' ... and read that statement carefully- electric resistance added heat is a pretty reasonable solution. An earth tube is actually theoretically 'free' heat.. if you ignore the install cost. I have 200'.. and mine was the lowest cost one. Also note- recirc- for those of you that are big on the cross flow issue with E/HRV's- what is recirculation defrost? Its 100% cross flow. Meaning- if you are exhausting from a pollution source (bathroom) - you will put that air directly to where you wanted fresh air (bedroom). Pleasant!

3. Reference above- 400 watts to raise the air temperature from 0-25 F. What are you saying here? You did not add anything to the thought. I will- so 400 watts for a 25 degree temp rise on 50 CFM continuous (meaning if it were 25 degrees below your defrost problem temp.. all the time... and you were at 50 CFM... Using the worse cases... electric resistance (COP 1) ... electric cost at $0.14/kwh... that is 5.6 cents per hour... Lets say i did that straight for 6 months... (note you will not have -10 F outside 24/7 for 6 months straight... but lets just say... SO- that is a total of $242 (or $40 per month). I would suspect that unless you live in an extreme climate- you would be at less than half that. Meaning- kwh for correctly modulated electric preheat when used for defrost of ventilation is not a big cost (not a big total KwH annual). Try comparing that to other defrost methods while getting the SAME amount of fresh air per hour. Talk about splitting hairs.

4. NO defrost needed at any temperature (say some manufacturers)- someone please explain this science and math to me? I cannot believe it.

5. Lunos no frost or condensation?- impossible. Or the ACH average heat exchange efficiency must be terrible? Again- please explain.

6. You need 'less ventilation when its cold outside'? My house has a blower door test of 0.52 ACH. My stack effect is nil. I need ventilation the most when i have my home sealed up for the winter. If you have a 'leaky' house... in which you can calculate that the natural infiltration is theoretically higher than the required ventilation rate for good IAQ... why are you putting in mechanical ventilation? I can give you other reasons.. but the math is not one.

7. Reference- HVI is a 'listing agency'. They do no testing. The third party performance test is CSA439 which all manufacturers test to- and then choose or choose not to list at HVI (added continued cost for what?).

8. HVI SRE in cold testing- right- electric preheat not included in the performance number- and actually only the last 12 hours of the 72 hour test is used for this performance number. Look at the watts used at the low temp- this will tell you the pre heat usage.

9. I'm not sure Semmelhack's article answered the question of- which 'used less energy'. It was not apples to apples in that regard. His question was- are they 'cost effective'. Disregard which house had the best IAQ at the lowest 'cost'. Those are different comparisons.

-with respect- and please excuse typos

Ultimate Air #8

The cold climate testing when you are listed with HVI or Energy Star (HRV/ERV with electric resistance pre-heating doesn't meet Energy Star standards) requires the testing for SRE and net ventilation rate results for the low temperature tests to be calculated over the last 60 hours of the

test versus the last 12 hours and it has to include a certain number of defrost cycles.

Also, an HVI listing gives other manufacturers a venue to challenge your ratings if they don't believe that they match reality and an assurance of continued verification of ratings.. Gives designers a little more confidence in the ratings knowing they are being monitored by competitors and a listing agency.

comments

Great comments and all probably correct. One note- when we were in the discussions with energy star prior to release of that listing- I presented the calculations that verified electric resistance heat was less annual energy use than recirculation defrost when considering achieving the same amount of ventilation (one must compare apples to apples). We were ignored. How do you deliver the same ACH requirement when outside is very cold... the most efficient....

In addition to exhaust only

Hi Martin:

It should be noted that while Zehnder ventilation units can function in "exhaust only" mode and thus total imbalance, the intake/supply fan also can gradually ramp down so as not to cause complete imbalance.

There are temperature sensors in each of the four air streams, and logarithms in the electronics that determine the optimal combination of continuous exhaust speed and variable supply fan speed so that total imbalance is avoided until it is the only solution.

Finally, until somebody provides a total installation cost of a dedicated, perfectly airtight, hard ducted ventilation system that, by the incorporation of sound attenuators and home runs that eliminate sound transmission, can I respectfully ask that you not characterize the system cost as being so high as to not be cost effective? This may be true if cost effectiveness is the only goal (and not a bad goal), but overlooks the addtional benefits of virtually silent operation, smaller duct sizes that fit within 2x4 walls, miserly Watts/cfm, excellent filtration, Zehnder-authorized balancing, etc.

Thanks!

John Rockwell

Lunos Freeze-Up

As a point of information, a friend of mine had his Lunos freeze up during operation this past winter in mid-coast Maine (image below). Admittedly, he sent along the caveat that he was operating them "out of spec" per the manufacturer's info. Outdoor temperatures were dipping below -10 F during this period, and interior RH was high enough to frost on double-pane windows (salvaged from Habitat ReStore).

Operations manual: https://foursevenfive.com/wp-content/uploads/2015/09/1121V2.2CT-Lunos-Operating-Manual-1.pdf

Did it damage the ceramic cores? @ Kohta Ueno

That's a pretty hefty plug of ice! Was it enough to damage them?

Did it damage the ceramic cores? @ Kohta Ueno

Hey Dana--my friend did not report needing to replace the units, so I'm assuming that once they were defrosted they worked all right. And an additional point from him:

Electric Pre-heat

An interesting document on HRV's in very cold climates is the 2010 report "Technical advice to Task Force on Northern Mechanical Ventilation Equipment Design and Testing". Anyone interested can find it here: http://aea.nt.ca/files/download/03feb646baca002

Here is what it has to say on electric pre-heat:

Supply air pre-heaters can be used as a frost avoidance strategy. These work by raising the temperature of incoming air high enough to avoid frost formation within the core. For a typical North American HRV, that would require pre-heating the incoming supply air to a temperature of between -5°C and -10°C. Raising the temperature of incoming air reduces the temperature difference across the core and consequently it reduces the amount of heat that can be recovered by the HRV. For example, cutting the temperature difference across the HRV by half also cuts the sensible energy available for recovery by the HRV in half, while the energy use of the fans, controls and other components remains unchanged. Operation of the heater may be costly, particularly if electrical heaters are used. As a result, this type of frost control is rarely, if ever, used in currently available HRVs. Exhaust air pre-heaters work in a similar way by heating exhaust air so that the core temperature will be too high to allow freezing. As with a supply air

preheat strategy, exhaust air preheat is inefficient and rarely used. Because of the dramatic reduction in efficiency that results from the use of electric heaters, HRVs with electrical heaters are ineligible for ENERGY STAR qualification in Canada. It is unlikely that an HRV with an electric defrost pre-heater would be capable of meeting the minimum SRE requirements at -25°C for ENERGY STAR even without an explicit exclusion for products with electric heaters.

Electric Pre Heat

The article does not address with calculations the overall most efficient means of delivering the minimum continuous ACH for a building as required by residential ventilation code/recommendation. I presented this math at the time and my math was not even reviewed. So- if not added heat- how do you do it and what is the energy penalty? Re-circulation defrost and exhaust only defrost strategies use more energy. Further- the argument that the heat transfer efficiency is lowered when the temperature difference is reduced- Highly efficient E/HRV's have 92%+ heat transfer efficiency at a 40 F degree temperature difference (72-32 which is the main test point). Defrost temperature thresholds are typically below this- meaning there is a bigger temperature difference than 40 F- meaning the efficiency is higher than the tested point (92%+) at what would be the defrost condition. When you have a 40+ delta and you change the sensible efficiency from say 92% to 88%- the change in delivered incoming air temperature is very small resulting in very little heat load difference. So again- someone find me the calculations. I have them. Unless you are doing an earth air tube or glycol coil ground loop- added electric heat is next in line?

Confusion for us common folk

I am no math or energy nerd by any means, but I’m trying to build energy efficient house and trying to learn as much as possible (that’s why I have a membership here). The confusion to learning what makes sense makes me wonder if this is why less people dive into “green builds”. For most people they like to buy things that make sense to them, so if product “A” is 94 efficient and product “B” is 90, then if price is similar they buy A. Example is me trying to purchase an ERV for my new build, looking at efficiency between units Venmar X24 ERV , Ultimate Air and Zehnder. Zehnder unit was out based on the HVI site rating, even though everyone praises this unit, cost was also higher (which also matters to us regular folk), so between the other 2 it was similar ratings, but the pre-heat was the difference. Again no real way for me to compare(apples –apples) what is more efficient, the comments above make things even more interesting and make me want to throw my hands in the air and say F-it just build a code minimum house( that’s what most the builders suggest anyway). So maybe it’s me just venting a little but as a consumer who wanted to build above code it’s not an easy hurdled to overcome. I think there may be a need for a consumer report on “green building products” GBA does an alright job (backyard tape test) and good articles on building techniques but it would be nice to have real world numbers/ratings/reviews/comparisons on new products or old.

Response to Kohta Ueno (Comment #23)

Kohta,

Thanks for your interesting comment, and the photo showing ice on a Lunos fan. I have edited my article in light of your report.

Martin, a correction for you regarding the Panasonic FV-04VE1 in cold weather. You stated that it runs only in exhaust mode below 20F. This is not correct.

At temps below -7C (20F) the unit runs at low speed (if set for a default of 40 CFM, it slows to 20 CFM) and will exchange air for 10 minutes, and then revert to exhaust only operation for 60 minutes. It's also worth noting that at the 40 CFM setting, the unit can only supply air at 30 CFM.

I have one in a cold climate and have confirmed the above.

Is it time to revisit the data on electric pre-heat vs recirculation defrost strategy??

I found some surprising information here from a 2020 NRC release that concludes that pre-heating HRV air was actually more efficient then relying on re-circulation strategy for defrost. They cover a lot of variables in the study:

https://publications.gc.ca/collections/collection_2021/cnrc-nrc/NR24-43-2020-eng.pdf

From the last page of the study:

6 Conclusion

An existing demonstration house in Iqaluit was equipped with an experimental DCV system consisting of an off-the-shelf heat recovery ventilator, two preheaters, a supply air heater, and a carbon-dioxide sensor, temperature sensors, and a microcontroller for custom control. The ventilation system was instrumented with thermocouples, an airflow sensor, and current transducers to monitor ventilation system performance. While long-term monitoring is ongoing, the short-term experimental data provided in this paper demonstrated the viability of low-cost residential DCV.

Although it is often thought that preheat consumes more energy than other frost prevention

methodologies, experimental results showed that this method can be acceptable if controlled well. It was experimentally shown that preheating consumed approximately 18% less energy daily (11.9 kWh/day compared to 14.5 kWh/day), than recirculating to defrost the HRV. Moreover, as a result of recirculation restricting outdoor air for approximately 20% of the time, the energy use of the ventilation system with electric preheaters per unit of outdoor air was actually 35% lower (12.9 Wh/m3 compared to 19.7 Wh/m3). However, the results also display that the performance of the two methods to prevent frost accumulation depend on the entire ventilation system design and operation, an aspect that needs to be explored more in the future.

Relying on recirculation as a defrost technique can cause the outdoor air supply to be cut off for a high proportion of time, which goes against the purpose of the ventilation system. For periods of high occupancy or humidity, preheating is an important technique to ensure sufficient outdoor air can be delivered to a space to maintain acceptable IAQ. Preheat also has the added benefit of reducing or avoiding cycles of condensation or frost build-up and removal from the core, which could result in a cleaner core between maintenance. Moreover, it is important to design building systems as efficient as possible; however, these systems must function and effectively serve their purposes. In the case of a ventilation system, the purpose is to provide outdoor air to the building and defrosting reduces the proportion of time when outdoor air is delivered, possibly to a point that is unacceptable to the occupants.

Log in or become a member to post a comment.

Sign up Log in