Image Credit: Rocky Mountain Institute

Image Credit: Rocky Mountain Institute This chart identifies key elements of solar PV projects, with the most critical causes of failure in bold text.

By LAURIE GUEVARA-STONE

and CHRISTOPHER BURGESS

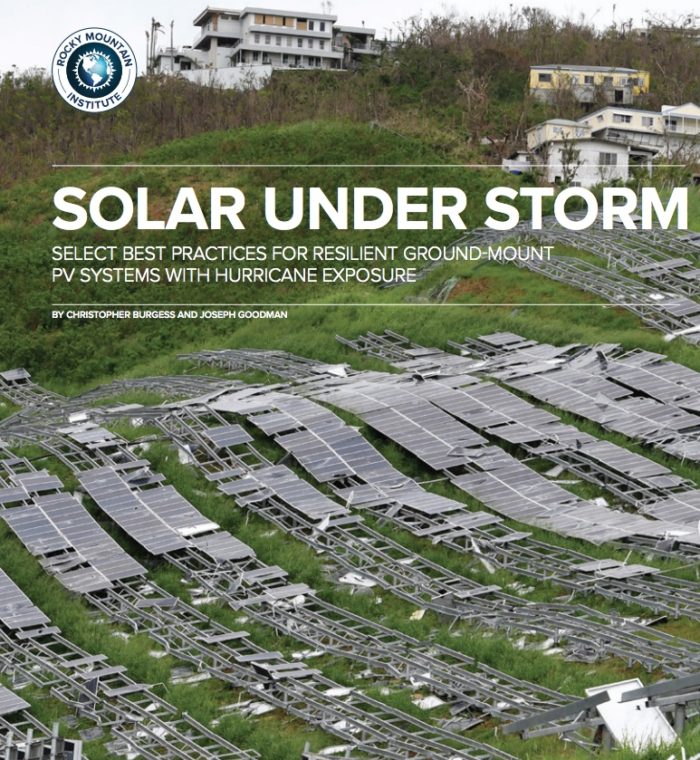

The 2017 hurricane season was one of the most active in history. Hurricanes Harvey, Irma, and Maria brought widespread destruction throughout the Caribbean. In addition to the emotional toll these severe storms had on people in the region, the disruption of critical infrastructure left many communities without basic services such as electricity and water for prolonged periods of time.

On some islands, such as Puerto Rico, the U.S. Virgin Islands, and Barbuda, photovoltaic (PV) systems suffered major damage or even complete failure. However, other PV systems, such as ones installed in the British Virgin Islands, Turks and Caicos, and St. Eustatius, survived and continued producing power the following day.

Rocky Mountain Institute’s (RMI’s) latest report, Solar Under Storm: Select Best Practices for Resilient Ground-Mount PV Systems with Hurricane Exposure, discusses the root causes of PV system failures from hurricanes and describes recommendations for building more resilient PV power plants.

Solar in the Caribbean

Over the past decades, electricity in the Caribbean was primarily generated centrally by imported fuel oil or diesel and distributed across islands by overhead lines. However, in recent years, electricity has been supplemented in homes, businesses, industries, government facilities, and utilities by photovoltaics. In fact, over half of Caribbean electric utilities already own or operate PV as part of their generation mix. There are at least 225 megawatts (MW) of solar installed across rooftops, parking canopies, and large tracts of land, and PV is the most rapidly growing source of power for many Caribbean islands.

While PV systems can provide lower-cost energy that is more resilient and reliable than imported fuels on many islands, it is not foolproof in the face of major natural disasters. The 2017 hurricanes brought sustained wind speeds of over 180 miles per hour to many Caribbean islands. RMI sent expert structural engineering teams to the Caribbean region in fall 2017 to investigate why some PV systems survived virtually unscathed while others suffered extensive damage.

Common attributes

The teams noted similarities between the failed systems, including module clamp failures, undersized racks, undersized and under-torqued bolts, a lack of bolt locking solutions, and a lack of lateral racking support. On the flip side, the systems that survived had the modules through bolted (no clamps), bolts with locking solutions, and lateral racking supports.

However, developing hurricane resiliency guidelines based only on observed failure modes has limitations. The observed failure modes may have served as a “mechanical fuse,” relieving forces from the system. If future systems address only those observed failures, forces may precipitate additional failure modes. To address both observed and potential failure modes, we used a common reliability tool for systematic cause and effect identification called a fishbone diagram. The diagram shows critical elements from the supply chain through design, construction, and operations of PV projects (see Image #2 below). The most critical causes of failure we observed in the fall of 2017 are in bold text.

Recommendations for hurricane resilience

The Solar Under Storm report organizes our recommendations into two categories: (1) specifications, and (2) collaboration. To the extent possible, the specifications are performance-based to allow for the most cost-effective and resilient solution. Collaboration recommendations identify opportunities for increased resiliency that require multiparty consideration and action but do not represent industry standard actions.

Specifications include:

- Using high-load PV modules (5,400 Pa)

- Requiring a structural engineering review and wind-tunnel report review

- Specifying a bolt hardware locking solution and bolt quality control process

- Specifying through bolting of modules as opposed to top-down or T clamps

- Requiring structural engineer review of lateral loads

- Not using self-tapping screws

- Specifying dual post pier foundations

Collaboration recommendations include collaborating with module suppliers, racking suppliers, and other equipment suppliers to implement the correct tests and ensure that equipment is consistent with assumptions used in engineering calculations.

Perhaps the most opportune recommendation is for a regional and even international community of PV power plant stakeholders whose plants have extreme wind exposure to regularly share lessons learned from new designs and extreme wind events. To that end, we formed a PV Resiliency working group on the online Caribbean Renewable Energy Community (CAREC), which is hosted by CARILEC, to connect, innovate, and collaborate.

The additional cost to increase resiliency

Calculating the additional cost to implement the recommendations in the report depends on the specific projects and sites. However, we estimate that a 1 MW ground-mount project on suitable soil and flat terrain in the eastern Caribbean would incur an increase of approximately 5% in engineering, procurement, and construction (EPC) costs when these best practices are implemented versus the standard category IV rated installation.

These additional costs come in the form of labor for the extra time needed to through-bolt the modules and install more foundation and racking supports. There are also additional costs in material (racking supports, dual post piers, and fasteners) as well as minor costs for additional engineering and construction oversight.

Based on RMI’s Islands Energy Program’s most recent PV procurement for a 1 MW ground mount system in the Caribbean, implementing the best resiliency practices would add approximately $90,000 in EPC costs to the budget. This overall project price increase is about the difference in module pricing from 2017 to 2018, and for Caribbean projects that procure modules later in 2018, the price drop could completely net out the additional resilient mitigation costs by year’s end.

Surviving the storm

Generating electricity with PV is a cost-effective and reliable solution for the Caribbean. There are major project plans across the region to not only add PV to the grid at utility scale, but also to install PV and battery systems for key critical facilities such as water treatment plants, hurricane shelters, schools, hospitals, and telecommunications nodes. Yet as the intensity and number of hurricanes rise, utilities, regulators, engineering professionals, and PV system developers and installers must be aware of the best available engineering, design, delivery, and operational practices to ensure these installations survive.

While the Solar Under Storm report cannot predict all the potential failures and consequent mitigation strategies, it provides an available set of best practices regarding specifications of equipment and procedures along with a framework for continued collaboration within a community of practice. Our hope is that by sharing best practices and through continued collaboration with designers, suppliers, and manufacturers, we can increase the reliability and survival rates of PV systems in hurricanes, and ensure that the people of the Caribbean have resilient and reliable power for their grids, homes, businesses, and critical facilities for decades to come.

©2018 Rocky Mountain Institute. Reprinted with permission. This originally appeared at RMI Outlet.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

5 Comments

Facility on St. Eustatius weathered the hurricanes well

I was glad to see that the PV facility on St. Eustatius was reported to have survived last season's hurricanes in good condition. (See the map below from RMI's report -- the St. Eustatius facility is indicated in green rather than red.)

For more information on the St. Eustatius facility, including information on its very large battery, see "A Caribbean Island Transitions to PV."

.

Other locations

I haven't seen any additional anchor support, beyond what comes with the panels, on installations here in the earthquake prone PNW. It's probably a similarly neglected aspect of the process that needs addressing.

One small quibble with the article. It seems whenever additional work is suggested by promoters of either structural or energy improvements, the increase in costs is almost always downplayed or dismissed using some pretty dubious logic. I think it's a counterer-productive strategy. For those with enough experience to judge, it serves makes them more sceptical about other aspects of the article, and it does a disservice to the inexperienced who may be mislead.

wind exposure

I would have guessed that site/topography would be a significant factor. For example:

"...an increase of 260% in the wind load that a structure on top of the hill would experience relative to the loads experienced by the same structure located in flat terrain."

https://journals.ametsoc.org/doi/pdf/10.1175/WAF-D-12-00050.1

calling out the engineers

It seems impossible that a unity would install thousands of solar panels without consulting an engineer. This article should be calling out the engineers by name that stamped the plans for the failed installations.

Walt

Calling out the engineers by name

Walter,

One engineer who got it right was Hamed Sadri, the SMA engineer who oversaw the project in St. Eustatius.

Log in or create an account to post a comment.

Sign up Log in