This episode of the BS* + Beer show features Kohta Ueno, Ben Bogie, and Doug Horgan talking about building sensors and data logging. They address the question: What Should We Be Measuring, and How Should It Be Measured?

Kohta delivers a rapid-fire explanation of how he monitors projects and conducts experiments, asking questions such as: What do I want to know? How does my assembly compare to others? Is the building’s orientation optimal? What are the key places to measure? How long will I have access to the building to monitor it? How can I vary the conditions to maximize the data set? When does high moisture content matter? He names a number of the instruments he uses, and advocates for redundancy—the more sensors, the better.

There’s talk of monitoring temperature, humidity, moisture, air leakage, and CO2 levels; heat flux sensors, Onset HOBO loggers, and Omnisense monitors; wired versus wireless setups; and zonal pressure diagnostics.

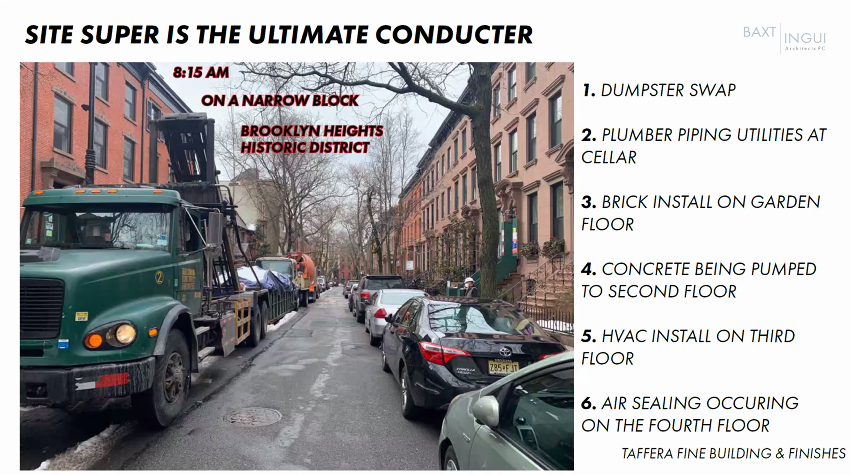

Ben offers this bit of advice: “Be as discreet as possible with the sensors’ placement to limit the disturbance in the wall assembly.” He also recommends monitoring buildings during all construction phases in order to collect real-time data, which he is doing on a current project. He demonstrates how the software he uses works, and what kind of information can be gleaned from it.

Doug encourages us to get cold, hard data on the HVAC system, outdoor conditions, and spaces outside “the problem area.” He says how you present the data to clients matters, and quotes the engineer W. Edwards Deming as saying, “Without data, you are just another person with an opinion.” And there’s plenty more where that came from . . .

To see Kohta’s presentation, go to https://www.buildingscience.com/past-events, and click on “Other Events.”

Enjoy the show!

Join us on Thursday, March 18, from 6 to 7:30 p.m. EST when we will discuss “Aesthetics vs. Performance” with architects James Hartford, Meri Tepper, and Bob Swinburne. Design goals can be at odds with building performance objectives. We will learn about instances when this happens, and how such scenarios might be handled to satisfy a project’s aesthetic criteria, while optimizing the envelope for longevity and energy efficiency.

Guest bios

James Hartford is creative/technical partner at River Architects, where he contributes his building envelope expertise and leads the sustainable design process for each of the firm’s projects. He is currently working on several Passive House projects that range from single-family retrofits, to multi-unit urban row house retrofits, to an organic hard cider mill in the Catskills. James is the founder and the past President of Passive House Alliance US- Hudson Valley Chapter. In that capacity James has brought Certified Passive House Builder instruction to Newburgh, NY, and Certified Passive House Consultant training to Schenectady, NY with significant funding from NYSERDA. These programs were the first of their kind in Upstate NY.

Meri Tepper is a licensed architect who received her Master of Architecture at the University of the Virginia. She performed postgraduate studies in Copenhagen and lead study tours through Scandinavia and Europe. Meri started her career at Ryall Porter Sheridan Architects in New York City designing highly custom modern homes. She was certified as a Passive House Designer, and that training in this building standard continues to influence her design approach. Meri currently lives with her family in Madison, WI where she operates her architecture practice and is the Director of Design at the Design-Build company, Associated Housewrights.

Robert Swinburne was a mediocre student in high school. Bob’s grades were fine and he was a band geek but he was too busy reading, drawing, and building things to bother studying. During the summer in Harrison, Maine, he worked for one of those people who could do anything. Bob didn’t learn to do everything but he learned a lot. After a few false starts at college, Bob found architecture school and it was good—time-consuming and expensive, but good. After graduation, Bob headed for the hills of Vermont, worked for several architectural firms and spent six years as a carpenter before becoming a licensed architect and starting his firm, Bluetime Collaborative. Bob lives in Halifax, Vermont, in a little house with a big barn, lots of woods, a wife, two kids, and assorted animals. He takes off into the woods every day with the K-9 patrol. Lots of people think Bob is a pretty good architect.

Use this link to register for The BS* + Beer Show

BS* + Beer Book Club

Because the hosts of the BS* + Beer Show all love to read, we thought we would celebrate the authors in our industry by adding a book club to the show every few months. We’ll announce the book, give you a few months to get it and read it, and conclude with a BS* + Beer Show episode where we will invite the author to join us, present, and take questions.

We have selected our third book: Essential Building Science: Understanding Energy and Moisture in High Performance House Design by Jacob Deva Racusin. New Society Publishers has generously extended a 25% discount for this book and others in their Essential Building Science series (paperback or ebook). Use the discount code Essential25 now through March 31.

We hope you will pick up a copy and join the discussion on April 1, 2021.

________________________________________________________________________

Kiley Jacques is senior editor at Green Building Advisor. She can be reached at [email protected].

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

5 Comments

As always, great info. A question for Kohta (and/or anyone else): when installing sensors in cellulose, do the sensors need to be protected from any of the cellulose additives? (e.g., borates) A thermocouple would be easy to protect, but humidity sensors and "wafer" sensors obviously can't be completely embedded in epoxy.

(Kiley, it looks like the direct link maybe got left out? https://www.youtube.com/watch?v=v88wNvcl0TU)

Hi Karl,

I'll send your inquiry to Kohta and get back to you with his answer. And thanks for alerting me to the forgotten link! It wasn't available when I wrote the post.

Hi Karl--

Great question--the borate content of cellulose can definitely screw things up.

As background to everyone else: cellulose insulation has borate salts as part of its makeup to act as a fire retardant and fungicide/preservative. When cellulose gets wet/damp, those borate salts can leach out or migrate into the adjacent wood (framing or sheathing). This actually helps in terms of protection of the wood from decay or damage. See this report, under 6.7 Protective Mechanisms: Cellulose Walls/page 46:

BA-1501: Monitoring Double-Stud Wall Moisture Conditions in the Northeast

https://www.buildingscience.com/documents/bareports/ba-1501-monitor-double-stud-moisture-conditions-northeast/view

However, if you're monitoring moisture content by electrical resistance, this can mess up measurements. Borate salts will change the conductivity properties of the wood, and thus mess up the moisture content measurements.

We have tried to fight this problem by protecting the moisture content pins with plastic tubing back-filled with sealant--see this report, page 20:

BA-2001: Monitoring of Unvented Roofs with Fibrous Insulation, Diffusion Vents, and Interior Vapor Control in a Cold Climate

https://www.buildingscience.com/documents/building-america-reports/ba-2001-monitoring-unvented-roofs-fibrous-insulation-diffusion

However, it was apparently not enough to solve the problem, at least when cellulose gets really wet. We got very unrealistic wood sheathing MC and wafer measurements in our cellulose results, which are consistent with borate contamination--see 7.5 Sheathing Moisture Contents on page 76, and 7.3 Ridge Wafer Conditions on page 71.

We've seen this problem in many of our experiments--unfortunately, no good answer other than having redundant sensors (i.e., relative humidity) to provide a reality check to unrealistic MC measurements if/when the occur.

In general, we have not seen problems with relative humidity sensors and borate preservatives. The relative humidity sensors are protected inside a "baggie" head (heat sealed housewrap)--it allows vapor diffusion but protects from physical damage and liquid water.

Kohta

Good explanation. We used goretex baggies rather than Tyvek but no difference I suppose.

We once set up 4 walls to study drying rates of wet spray cellulose with different coverings. We used thermocouples, pins, and bagged rh sensors. It was evening when we finally got ready to spray. Suspense. They sprayed and we watched the readouts. The temperature started climbing 20C, 25, 30, 40, 50 on up to 100 and more. Lesson learned: excitation voltage for the pins turned the whole assembly into a circuit that nuked the thermocouples. I proposed doing a conference with Hartwig Kuenzel years ago on the subject of “you won’t believe what we just measured”.

Wow, replies from not one, but TWO building science superheroes! Thank you both, Kohta and Bill, for your detailed explanations, and thanks to Kiley for reaching out on my behalf.

For anyone else interested in DIY instrumentation of these assemblies, the Ueno/Straube 2008 presentation has a description of the wafer sensor (slides 5 + 6):

https://www.buildingscience.com/sites/default/files/Wood_RH_Sensors.pdf

I imagine that applying an excitation voltage (e.g., +12V) only for the duration of the measurement itself might help the situation a bit.

Log in or create an account to post a comment.

Sign up Log in