Andersen Windows’s 1952 introduction of the Welded Insulated Glass panel was a big deal, at least for homeowners in the northern tier of the country. Now, consumers could buy an assembly that married two sheets of glass and an insulating layer of air in a single glazed product. For untold numbers of homeowners, Andersen’s commercial launch meant an end to the drudgery of storm windows.

More importantly, it was the start of an industry that in the last 70 years has incrementally improved the thermal performance of windows several times over. Multipane insulated glass units (IGUs) combine metallic coatings, inert gas fill, and insulating spacers in assemblies that make houses more comfortable and lower heating and cooling costs. By tweaking the characteristics of low-emissivity (low-e) coatings and applying them selectively, glass makers can customize IGUs for specific needs and climates.

Even with the best coatings and insulating gas fills, glass makers are fighting an uphill battle. The best glazing makes a poor insulator when compared to the exterior walls of a high-performance house. Walls in a Pretty Good House would be rated at roughly R-40, for example, while high-quality triple-glazing might have a U-factor of 0.15, the equivalent of just R-6.6. The 2018 version of the International Energy Conservation Code calls for a minimum U-factor of 0.32 (roughly R-3) for windows in even the coldest parts of the country.

At the same time, work continues on new technologies that could make better windows more widely available. They include vacuum units, triple-pane designs with an ultrathin center pane, and suspended film units with as many as eight internal layers and a center-of-glass insulating potential of more than R-19.

Basic considerations

The thermal performance of glazing and complete window units are two different things. IGUs may come with very low center-of-glass U-factors (high R-values), but…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

10 Comments

Very interesting. Thank-you, Scott.

It is good to have an update on where all these different technologies have gotten up to now.

Can someone explain to me why the glass industry uses 'U' values and not 'R' values? I have never had this explained to me that made any sense.

From what I know, U factor is actually more of an industry standard and can be used with many different assemblies. R value is the inverse of the U factor, and that number (the R value) is easier for consumers to understand. I can't vouch for what I'm about to say, but it's my understanding that R value is driven my sales/marketing.

Nathan,

The response from Pioneer Builders is accurate. Scientists have used U-factors for decades. R-value was invented to help marketers of insulation -- since marketers assume that consumers are confused by the idea of "a lower number is better."

For more information, see "All About U-Factor."

I hear what you are saying, but it's like someone would say 'I'm 0.01470" tall, inverted' Consumer speak seems to make a lot more sense to me, as you can understand the order of magnitude way better than the minutiae of an inverted number.

Hang around the contractor sales desk at a lumberyard for a hour or so and you will hear at least one confused customer trying to buy thicker brad nails or flashing by asking for a higher gauge.

Nathan,

On the contrary, R value tends to be more misleading in how it conveys "order of magnitude" to consumers and even professionals. For example, an R20 assembly is not 'twice as good' as an R10 assembly, nor would it 'double' your energy savings. It is only 50% better at reducing heat transfer through that assembly at design test temperature, as determined by ASTM or NFRC etc.

Good article!

Scott, thanks for the good article! I'm curious if "thin triple" windows is still in the works at Andersen. And if not, for what reason? Alpen is now selling a "thin triple" alongside its suspended film windows. I've reached out to Andersen Windows but no one knows anything about it.

Great article, lots of interesting details, fascinating technology!

However…

Doesn’t mean diddledeesquat! The window manufacturers in the US don’t give a flying hoot about insulation properties! Nor sound proofing, nor anything else!!!

Try to find r-values, or u-values, or db-values or anything like that on their websites! It ain’t there!!!

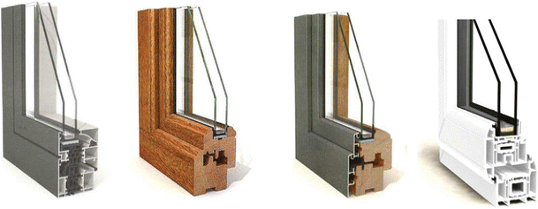

Going by European windows manufacturers (for example: https://www.hrachowina.at/wp-content/uploads/2019/02/PRINT-E16-J-5152-hr-fensterkatalog-18.jpg), it appears that the glazing isn’t the problem. Rather the frame!

And that is with the highly sophisticated frames these guys over there produce. The frames in the US are an embarrassment of human design at a minimum! Doesn’t take an engineering degree to see how inefficient they are!

Ever saw a crosscut? In Austria that’s the first thing you’re being shown! In the US it’s simply not available, asking for it just results in blank stares!

The issue is, i think, that consumers don’t know to care, and manufacturers do not want to open a pandora’s box…

I for one, gave up on US produced stuff. I imported my windows from Austria. And every person that comes to visit comments on how awesome they are! Looks, functionality (tip&turn), sound cancelling - and when i tell them about the energy efficiency, those who care get all exited!

PS: my parents installed such windows in 1977. Until now, not a single one is drafty, hard to close, or has moisture in the glazing!

The windows i just replaced in my house here where from 1999 and 2009. All of them needed wood sticks to keep them open! All of them where drafty that you can feel it by holding your hand there! Terrible (non-)quality!

Don’t get me started about windows… 😝 oops! Too late! 🤷♂️

Log in or become a member to post a comment.

Sign up Log in