In hot climates, high-performance homes have to mitigate solar heat gain for much of the year, and windows are often the culprit when things are uncomfortable and inefficient. Here’s a guide to the window performance specs required to do the job and some recommended products.

I don’t consider myself a window expert, but since I design custom homes that follow the guidelines of the DOE’s Zero Energy Ready (ZERH) and Energy Star programs exclusively, I’ve educated myself to be able to advise my clients to look for climate-appropriate, high-performance windows that are easy on the budget. (Of course, there are clients who make selections regardless of price; they are generally interested in aesthetics before performance.)

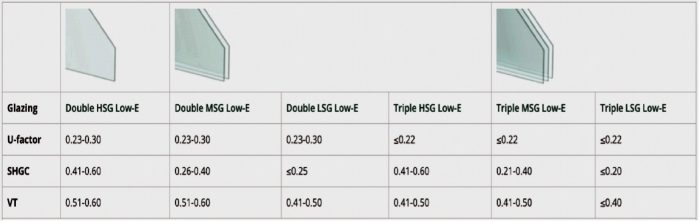

Most of my projects are located in climate zones 2 and 3, where Energy Star requires windows with a U-factor of ≤.30 and a SHGC (solar heat gain coefficient) of ≤.25. Fortunately, most window retailers in these regions stock windows that fit within those guidelines; they are the most commonly installed in these markets.

Energy Star–rated windows:

- Are manufactured by an ENERGY STAR partner;

- Are independently tested, certified, and, verified by the National Fenestration Rating Council (NFRC);

- Have NFRC ratings that meet strict energy efficiency guidelines set by the U.S. Environmental Protection Agency (EPA).

Although Energy Star requirements do not include specific technologies, certain features are common in many certified products. If you are designing a high-performance house—especially if it is one your client plans to certify under a green building program—there are a few critical things to know, starting with materials.

Window frame materials

There are several materials used in high-performance windows. The more popular windows in the South are vinyl, fiberglass, composites, and wood-clad, but you still find wood and aluminum window frames too.

Vinyl, fiberglass, and composite frames are valued for their energy efficiency and low-maintenance requirements. They are offered in a variety of colors that resist fading, and some are manufactured using recycled materials; in some cases, too, components are easily recycled. Additionally, some manufacturers make thermally-broken frames. Windows made from these materials tend to be good choices for the cost-conscientious buyer.

All-wood frames have a long lifespan but only if they are maintained properly. Such windows require annual care—in the form of a full coat of paint and seal—to ensure resistance against rot and insect damage, energy efficiency, general functionality, and aesthetics. Cost-wise, all-wood windows fall between vinyl and wood-clad windows.

Wood-clad frames are an upgraded version of all-wood frames. They offer the look of a wood frame and the low-maintenance requirements, insect- and rot-resistant characteristics, thermal efficiency, and structural integrity of vinyl, composites, or aluminum clad-frames. Wood-clad windows offer many natural woodwork stains and paints on the inside, and on the outside, many color finishes and style choices to go. These windows are usually a much higher cost.

Aluminum frames are lightweight and strong, require little upkeep, and do not rust or rot. They also have narrow profiles, which are desirable for modern homes. But I offer this warning: Do not buy aluminum-framed windows if they are not thermally-broken. They are highly conductive, which increases the potential for condensation. You want windows with non-conductive materials between the frame and panes to avoid condensation issues. Aluminum frames are water-resistant, but they are susceptible to corrosion from saltwater and sea air. Additionally, because metal expands and contracts with temperature changes, aluminum frames are more likely to end up with seal failures than, say, a vinyl window.

Choosing the right glass

There are many options for window coatings—from insulating to UV blocking, privacy to safety and security, and even decorative. If you want coatings on your windows, make sure they are factory installed and come with a warranty.

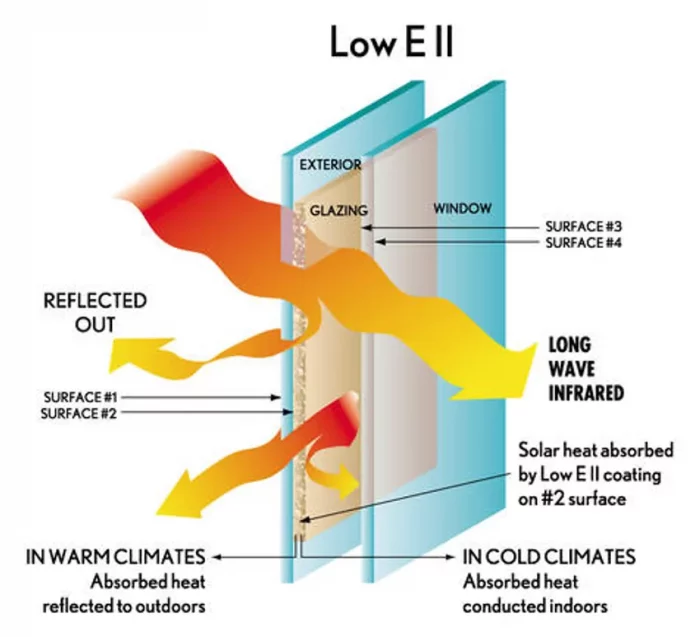

Southern homes benefit from mild winters but have uncomfortable hot and humid summers, which is where low emissivity (low-E) coatings come into play. Low-E insulating glass with argon gas features three layers of thermal protection to reduce solar heat gain while maximizing visible light. Such windows keep cooling costs down. Low-E glass reflects heat energy either into or out of the house, further enhancing insulation. It also reflects ultraviolet (UV) light away from the house and can protect your household furnishings from UV-induced fading by as much as 75%.

Low-E units have a coating on one surface of the glass that reduces energy transfer. The coating protects the window from ultraviolet and infrared light while allowing visible light to be transmitted. For hot-weather climates, where air conditioning is prevalent for most of the year, the preference is to have windows with low U-factor and UV blocking. They need to reflect invisible solar heat radiation in order to save on electricity usage.

The role of gases

Windows are filled with different gases—including argon, krypton, and xenon—to displace the air between the panes. This slows thermal transfer, which means selecting the right glass for your climate zone can help reduce heating and cooling loads. Even though window gases leak about 1% per year, most reputable windows remain highly efficient even after 20 years.

(Note that gas-filled windows purchased from manufacturers who ship from the East Coast to the West Coast and vice versa come with some risk. When the windows transition between low and high altitudes, their seals are susceptible to breaking and the inert gas can leak out; moisture from outside air can then seep into the space between panes. So consider your source when buying.)

What to know about spacers

Most high-performance window manufacturers are making spacers their top priority in order to improve their products’ energy efficiency. The wider the spacer, the less transference of temperatures from one pane to another.

Spacers are strips of composites, foams, thermoplastics, metals, or a combination of several materials bonded to separate, support, and seal in gasses that have been injected between the panes of glass to form an air-tight seal. Spacers not only help seal the two or three panes of glass, but also control expansion and contraction of the glass within the window frame, provide structural integrity, and enhance condensation resistance and temperature transference between panes while keeping the panes dry.

Spacer technology has improved in the last decade or so. There are metal spacers made of aluminum, stainless steel, or alloys, but they are more susceptible to seal failures. Metal with foam and composite or plastic spacers provide somewhat better efficiency. Foam or EPDM spacers are arguably the most energy-efficient spacer, and reduce heat and cold transfer significantly compared to other types.

Performance ratings

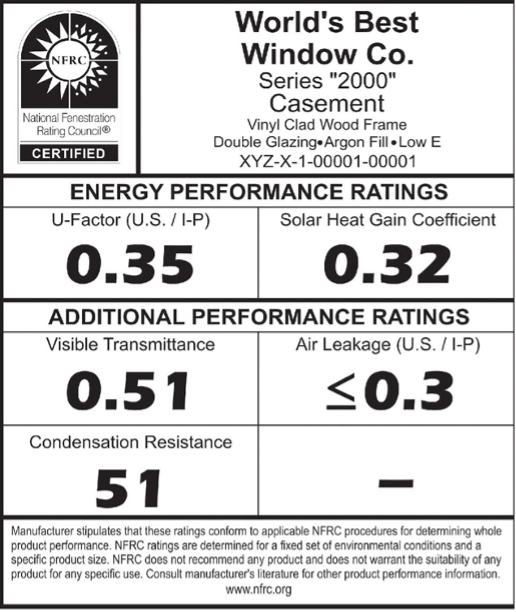

While the Energy Star and the ZERH programs set the minimum requirements for glazing in homes within climate zones, the National Fenestration Rating Council (NFRC) certifies products that are independently tested and labeled to help consumers make the best decision for their needs. It allows consumers to compare labels between different energy-efficient windows by breaking down the windows’ energy performance into five categories.

U-Factor measures how well the window insulates. The window transmits non-solar heat flow and has the ability to keep heat inside your home. The lower the number, the better a product is at keeping heat in. Range: 0.1–1. Look for: Low numbers; best ≤0.30

Solar Heat Gain Coefficient measures the amount of solar radiation admitted through a window unit—either transmitted directly and/or absorbed. Lower numbers mean you’ll spend less on cooling your house. Range: 0–1. Look for: Low numbers; best ≤0.25

Visible Transmittance measures how light passes through a window unit. The higher the number, the more natural light is let in. Range: 0–1. Look for: Low numbers to save energy, high numbers to let more light in; best .50

Air Leakage measures the amount of air movement at a specific pressure in a particular window unit. Lower numbers mean fewer drafts. Range: 0.1-0.3. Look for: Low numbers; best 0.1 (Window style is a big factor; picture vs. double-hung, etc.)

Condensation Resistance measures resistance to condensation in a window unit, and is more of a thermal bridging issue. The higher the number, the more resistance to condensation. Range: 1 to 100. Look for: High numbers; best ≥0.50

My recommendations

Let me say upfront: In the South, the best window for a house is the one that is shaded under a porch, and the bigger the overhangs the better, PERIOD!

Having said that, I prefer to specify windows that have a full nailing flange—not those that have cut-out corner flanges for shipping. Those sticky corner foam jigamarees get lost all the time, and when you finally find them, they are dirty or torn—and don’t get me started on flangeless windows. Have you tried to explain to a builder or framer how to waterproof those? No thanks.

There are three window brands I like to recommend and specify, mainly because they are high-quality products that come with a warranty and good customer service. They are Sierra Pacific, Andersen, and Pella. I gravitate to brand representatives that make the extra effort to help and retailers with streamlined ordering processes and punctual deliveries.

Of course, cost is a factor. A couple years ago, one of my HERS raters did a cost analysis for a client who wanted triple-pane windows here in Texas. The rater found that even with the most energy-efficient windows, it would take 32-plus years to justify the cost. That said, triple-pane windows can be a good option if you live in a noisy urban area, as that extra pane of glass makes a big difference in sound reduction.

For my ZERH projects, which typically measure 1 ACH50 and HERS ≤43, my clients’ selections are based on price, aesthetics, and performance. The most common windows I specify are aluminum-clad, vinyl, or composite frames with Cardinal Lo-E 366 glass, U-value ≤.30, SHGC ≤.25, VT .50, with Argon-gas fill between the panes and black-foam spacer. In coastal areas and Tornado Alley, I spec laminated glass. Those recommendations have served my clients living in hot climates.

_________________________________________________________________________

Armando Cobo is a zero-energy custom home designer, trainer, and building consultant working in Texas and New Mexico.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

21 Comments

Good article.

It would be nice to have a follow up article on the proper installation of windows, i.e. how to make sure windows are installed properly by a sub-contractor.

Thanks, William. It looks like I'll follow up with window installation at some point.

William,

You can find numerous articles on just that by using the GBA search function to look for "installing windows".

Have been doing that, jake Bruton has excellent video on Fine HomeBuilding. I used to work for Andersen and installation was the biggest problem. You can make great windows but they can be ruined quickly by a bad install.

I hear you on the flange-less windows. I was distracted by my perception of the excellence and clarity of the installation instructions at 475 building products. e.g., https://foursevenfive.com/blog/how-to-prepare-for-high-performance-windows/ And so I looked for flangeless windows. And we were a concrete block house which is one of the applications for flangeless. But the window companies could not provide any installation instructions (at all, just pointed to "industry standards"). It was a pointless, frustrating roundabout.

Condensation resistance is also key (as you point out) but again, almost none of the manufacturers really had that data available and thought I was very strange for asking. Some clarity through something like a Manual J for knowing what condensation resistance can be expected (or is required) in different climates would be a really useful addition here.

Finally, fiberglass windows seem to me to be more subject to expansion/contraction than I expected. I have the Alpen windows in fiberglass and the doors especially feel different in operation than I expected.

As an Arizona resident, I appreciate the knowledge! Overhangs are always key, but it's always amazing how certain windows (and patio doors) can feel like a space heater when you walk past them. Windows are such a huge component of a building's overall comfort.

A couple of clarifications:

1. "For hot-weather climates, where air conditioning is prevalent for most of the year, the preference is to have windows with low U-factor and UV blocking. They need to reflect invisible solar heat radiation in order to save on electricity usage."

As explained correctly later in the article, U-factor refers to heat transfer other than solar radiation. For a hot climate, you want low U-factor to prevent heat from the hot outdoor climate from getting in. The low U-factor doesn't mean that they "reflect invisible solar heat radiation" -- you need to also make sure to get low SHGC to make sure they are reducing the solar gain.

2. In the U-factor description, it says, "The lower the number, the better a product is at keeping heat in. " It's useful to understand that the U-factor works both ways. A low U-factor window is just as good at keeping heat from the surroundings out as in a hot climate as it is at keeping interior heat in in a cold climate.

Once you understand SHGC and U-factor, that's really all you need to know to know what performance to expect. You need to to worry about what gas they used or where they put the coatings--all of that is fun and interesting, but if two windows are built differently and have the same SHGC and U-factor, they will work equally well at keeping you cool.

Nice article Armando. Lot's of great information in one place. It took me hours in various sources to find some of that. A couple questions:

"Having said that, I prefer to specify windows that have a full nailing flange—not those that have cut-out corner flanges for shipping. Those sticky corner foam jigamarees get lost all the time, and when you finally find them, they are dirty or torn—and don’t get me started on flangeless windows. Have you tried to explain to a builder or framer how to waterproof those? No thanks."

This would eliminate all of the European tilt and turn windows of any material and the aluminum ones fashioned on that style? It would also make finding passive certified a bit trickier? From my research and discussions with them they tend to use anchor straps or something similar and then specify the installer overlap tape on the window frame for waterproofing. I agree that it is much simpler and more robust to apply an "upside down U" of sealant around the window opening, seat the flange into the sealant and tape over the flange.

"The most common windows I specify are aluminum-clad, vinyl, or composite frames with Cardinal Lo-E 366 glass, U-value ≤.30, SHGC ≤.25, VT .50, with Argon-gas fill between the panes and black-foam spacer."

Do you specify i89 on the 4th surface? Or is it more a budget issue?

"That said, triple-pane windows can be a good option if you live in a noisy urban area, as that extra pane of glass makes a big difference in sound reduction."

One of the window manufacturers told me it was useful for noise to have different thickness of glass in the three panes to provide better disruption of sound waves. It seemed to make sense, but I haven't researched it. Triple pane is also useful for the perception of cold or heat when you are close to the glass. Not sure how much difference it makes, but I chose triple for the window beside the bathtub and ones where people would be close to the glass based on use patterns. Specs on the double glazed were very good with i89 coating and close to triple glazed.

Thanks, Allan. Back in the late 80s and early 90s we used home-built picture (no flanges) and wood windows, and we started having sooo many problems, that I learned about Andersen and Weather Shield and used them for a long time. In time I added Pella and Sierra Pacific to my list. I’ve never specified a European window, and unless a client wants it, I would rather stay ‘merican… there are plenty of good windows made here, giving work here. I haven’t done a Passive House either, I’ve stayed with ZERHs for now, so I can’t help you on those two fronts.

To my knowledge Cardinal i89 Glass is used more for cold climate windows, since it has an energy-saving 4th surface coated glass. I’ve used it a few times in Northern NM and Southern CO. Here also is where triple windows may be cost effective, but those are windows we don’t typically use in the South.

As I said above, I don’t find triple-pane windows needed nor cost effective in our climate zones 2 & 3. I’m designing a house now that the homeowner is talking about getting triple-pane for noise reduction.

I don't know how well that mixed-thickness glass would actually translate to noticeable real-world gains in a house, but having different glass thicknesses would provide a different amount of mass damping (and stiffness) for each pane of glass, which would change the frequency range for any given size of window. Changing the spacing between the panes will also change attenuation. Or make all the panes of glass thick, which would be more attenuation but at a more narrow range of attenuation frequency.

Or mix in some laminated safety glass, which I understand has better attenuation because of the laminated safety film.

And this all depends on the size of windows and the overall glazing area, etc...

That does bring up an interesting point: Is there a sweet spot for attenuation performance versus cost for residential windows?

Is it a mixed/asymmetrical thickness glass package, or just thick glass, or just a very thick IGU spacer, or some combination of those things?

I would think the commercial glass world has answers to all of these questions, and have done the math (and done the measurements). Maybe it's well understood, but doesn't trickle down into the residential world with different market constraints.

Allan C,

Like Armando, I much prefer windows with flanges. Having used both vinyl and wood ones that came with detachable flanges, I wonder if it wouldn't be possible to simply add them to the windows you prefer, to make the installation similar to what you are used to?

Malcolm,

To my knowledge none of the European windows I looked at have this option. I was told it's to accommodate the variations in wall thickness found in Europe and allow them to be installed as "outies" or "innies". I believe this is why they recommend installation with the windows or at least installation training and supervision. The thought of having all my windows come in a container from Europe with all the stuff going on in the world was more risk than I was prepared to take.

I ended up ordering windows with extruded aluminum flanges. They were a pricey option, about 6% of the cost, but I asked my builder and he said yes, so I did it without really thinking about it. I'm glad I did that now realizing how much easier they will be to seal and waterproof in the rough opening.

Allan C,

Yeah, I've never been able to get my head around buying European based products with no local support.

I was suggesting installing flanges once the windows are delivered - although that might not do wonders for the warranty. The ones I got with wood windows were just clipped on and then caulked.

I install flanged windows very similarly to what's shown on this video, except I include a code mandated metal head-flashing, bedded in caulking, with end-dams. https://www.youtube.com/watch?v=SqP4liutJFs

All the water damage to windows I've seen when renovating has been confined to the sill and lower jambs of the rough framing - mainly the result of leaking around the brick stops. A flanged window and a sill pan deal with that if installed with a small amount of diligence.

"I'm glad I did that now realizing how much easier they will be to seal and waterproof in the rough opening."

Ha! It takes many years for some people to figured that out, and some never will! 🙄

Thanks for a southern builder's perspective and the real-world, first-hand experience.

Hi, Armando.

This article is well-timed for me. I'm going to be building a house up in Anna, so I always enjoy reading your articles, and your hot-climate comments on other cold-climate articles. I appreciate your expertise and experience, and will be hewing closely to your recommendations.

Regarding double vs triple glazing, what kind of cost premium is there? Are we talking 5%, 25%, 50%? I am keeping in mind longevity of the house, our predicted hotter future, and the building site is near railroad tracks, so I'm leaning toward triple as long as the cost doesn't blow up the budget.

It’s my experience that a good triple pane windows vs good double pane, of compatible materials, costs are in the 25%-50% higher, and that depends where the windows are manufactured. One client told me that he prized some European triple pane windows at twice the cost of a good American double pane window.

IMO, the energy efficiency of the triple glazed vs. the double glaze windows is not high enough in southern climates, but if you are looking for an STC improvement, then triple glazed windows maybe worth the cost.

I big issue for me is availability in this day and time with all the supply issues we’re having in our industry… that just creeps me out!

Armando,

There is a host of good information in your blog and a really great read, but I do have a few nits to pick....

"Most high-performance window manufacturers are making spacers their top priority in order to improve their products’ energy efficiency".

Agree that window companies are paying a lot more attention to their IG systems than they used too. IG units come either preassembled from an IG manufacturer or they can be assembled by the window company on site. If preassembled the vast majority come from Cardinal, but there are a number of smaller more or less regional or local (sometimes with only a single customer) IG assemblers as well.

Cardinal IG units use either the XL or Endur spacer, both are stainless steel and are only available from a Cardinal IG plant as a complete IGU.

Window companies or other IG manufacturers have a wide variety of spacers to choose from with the same spacers available to either. The primary spacer used by window companies or IG producers other than Cardinal is the Intercept from Vitro (formerly PPG). This spacer can be either tin-plated steel or stainless steel. The stainless version is pretty good, the tin-plated less so. The two most commonly used non-metal spacers are Superspacer and Duralite. Intercept, superspacer, and duralite are all available to either IG manufacturers or window companies.

I am retired for 3 years and haven't seen a detailed report during that time, but last time I looked before retirement spacers used in North America were about 1/3 Intercept, 1/3 Cardinal, and the remaining 1/3 everything else including aluminum and all the non metal systems combined, and even a couple other stainless steel systems as well.

Percentages listed cover residential with a smattering of architectural and light commercial included as well.

"The wider the spacer, the less transference of temperatures from one pane to another".

Not precisely since widening the gap between the two lites increases the potential for convection currents in the air space. Depending on the coating used, as well as glass thickness, you may start to see slight performance degradation at as narrow as 5/8" to 3/4".

Argon, krypton, et al., improve performance at least as much because of their effect on convective currents as on lowering conduction between lites.

The sweet-spot for best IG performance is about 7/16"-9/16", again depending primarily on coating used.

"There are metal spacers made of aluminum, stainless steel, or alloys, ..."

Grouping aluminum and stainless steel spacers as a single subset of spacer materials is something that the non-metal spacer manufacturers like to do because they can then publish stats related to aluminum and use those stats to cover "all metal spacers", when in fact there is a greater performance disparity between aluminum and stainless than there is between stainless and non-metal products.

"...but they are more susceptible to seal failures".

This is not correct, in fact stainless spacer systems have been shown to have better long term performance than non-metal systems. Going back to Cardinal again since they manufacture the IG system and not just sell spacers, the XL was introduced in 1992 and was sold with a projected seal failure rate of .25% over 20 years. The actual failure rate has held steady at .20% to 30 years and counting. No non-metal (or any other spacer or IG system for that matter) comes close to that performance. Cardinal currently has over 500,000,000 IGU's under warranty with another couple hundred million past warranty coverage.

Energy performance does favor the non-metal systems, but not by as much as people believe. For example the very best (energy performance) Superspacer variant is .8°F warmer at the edge than is Cardinal's Endur, the follow up to the XL, with the stainless Intercept very close to that as well. The warmest at the edge non-metal is the Duralite, about 1.5°F warmer than Superspacer.

Thank you for adding valuable insight information to the blog.

You're welcome.

My intent was a few short comments, but I think I am incapable of being brief.

And I forgot to mention that I agree whole-heartedly that providing shade for the windows has to be the priority as much as possible.

Log in or create an account to post a comment.

Sign up Log in