To understand how USG Sheetrock® Brand EcoSmart gypsum wallboard (GWB) has a better environmental footprint than many alternative wall coverings, it helps to know how it is made.

The key is two different gypsum crystals

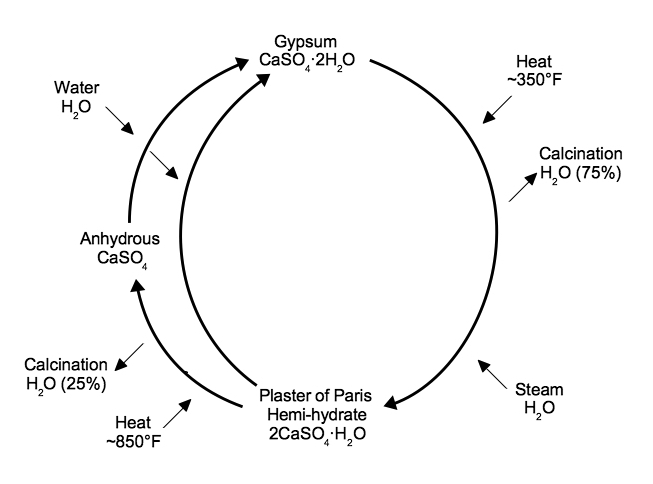

The mineral gypsum comes in two different crystal forms: Calcium sulfate dihydrate (CaSO4 2H2O) is how the molecule is found in nature. Calcium sulfate hemihydrate (2 CaSo4 H2O) is created through a process of grinding and heating the calcium sulfate dihydrate molecules.

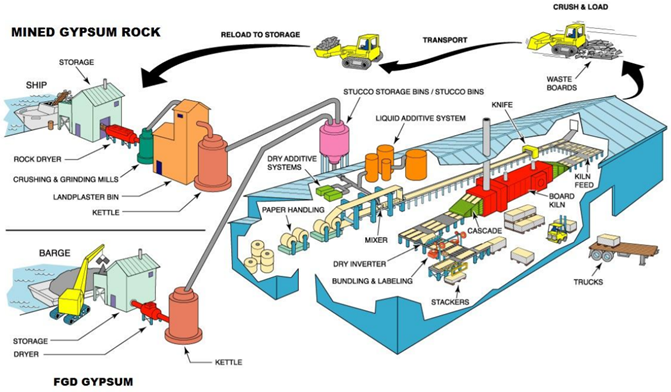

The first step in making GWB is to mine the gypsum dihydrate or collect it as flue-gas desulphurization from a coal-fired power plants. Step two is making the hemihydrate by grinding it and driving off water by heating it. The gypsum wallboard industry calls this material “stucco.” It’s a very fine powder, a lot like wheat flour in consistency.

If you take that incredibly fine powdered gypsum, mix in some key and proprietary additives, you can turn it into a slurry by rehydrating it with water. Adding water will move the crystal structure back to the dihydrate form, but in the process manufactures can form the recrystallizing dihydrate between two runs of paper to make gypsum wallboard (see the manufacturing diagram below).

In standard GWB manufacturing, about four times more water than required for recrystallization is added and a lot of energy is used to drive off that excess water. USG EcoSmart board uses special additives to reduce water use in the manufacturing process. The result is:

- GWB made using 25% less water

- 20% less CO2 emissions (reduced drying energy with less water in the board)

- 20% lighter board

- 20% less fuel consumption during transportation of the finished board

Why not make all board this way?

I asked USG this question and not surprisingly, the one downside to EcoSmart is cost. A USG representative told me that for ½-inch sheets of EcoSmart available at a big box store, there is a 10% to 15% premium. The EcoSmart premium is about half that for the 5/8-inch Type X EcoSmart board used throughout the commercial building industry.

The result is that ½-inch EcoSmart board has a pretty limited market share while the 5/8-inch Type X EcoSmart board is about 35% of USG’s Type X total sales. Clearly, the significantly better eco-footprint of EcoSmart GWB and its lighter weight labor savings is more important in the commercial building industry than the residential construction side.

And rumor has it that some Home Depot customers were even less tolerant of the EcoSmart premium because they thought that the “Eco” stood for economical not ecological.

EcoSmart board has solid “eco-cred”

BuildingGreen recently reviewed EcoSmart panels and stated this:

“Compared to standard drywall, EcoSmart has a better environmental profile, equal or better performance in most applications, and is cost competitive. It also has the following certifications and transparency documentation:

- Greenguard Gold certified for emissions

- Declare Red List Free

- LEED v4 compliant Type III EPD

- 1 Health Product Declaration

EcoSmart GWB also meets Architecture 2030 for products based on carbon emissions from manufacturing, according to USG.

Impact of less-dense board on acoustics and fire-resistance

It’s mass that largely deadens sound transfer in GWB and it’s the water in the dihydrate gypsum crystal that contributes quite a bit to GWB fire resistance (it takes a lot of energy to drive off the water in the gypsum crystal).

So, if EcoSmart board is 20% lighter or less dense, doesn’t that decrease acoustical and fire performance? I spoke with more than one technical representative at USG about these properties and was told that was “…the really challenging part of the EcoSmart formulation, but also the proprietary part. We have the test results to prove that EcoSmart board maintains acoustical and fire-resistance properties compared to standard GWB but we can’t give you the secret.”

Some industry perspective

I talked with Steve Rapoport, Territory Manager for Kamco Supply Corp in Williston, VT. They sell an awful lot of USG EcoSmart board. Steve was more than happy to connect me with some of his customers, drywall contractors using USG EcoSmart board. I caught up with Travis Dashnow of Hardrock Drywall of South Burlington.

“The only Type X board we use is USG EcoSmart,” Travis told me, “It’s the weight and quality of the board for us. We look for innovation in our work and EcoSmart’s reduced weight is a big deal.”

When I asked Dashnow about the price premium, he said, “More than happy to pay a bit more for this board—about 7% for us—and lift 20% less weight over the course of the day.” Dashnow went on to say that since USG Ecosmart can be used in place of the even heavier Type C ceiling board, it’s even easier for his company to stick solely with EcoSmart board.

I asked Travis if he ever sees EcoSmart board specified by architects because of its certifications or environmental performance. “We are starting to see this a bit in our work,” se replied, “but since we only use EcoSmart, it’s fine with us for architects to spec it.”

Learn more about USG’s EcoSmart here.

-Peter Yost is GBA’s technical director. He is also the founder of a consulting company in Brattleboro, Vermont, called Building-Wright. He routinely consults on the design and construction of both new homes and retrofit projects. He has been building, researching, teaching, writing, and consulting on high-performance homes for more than twenty years, and he’s been recognized as NAHB Educator of the Year. Do you have a building science puzzle? Contact Pete here.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

13 Comments

For my personal projects, I would gladly pay the extra 10% if it meant the wallboard was 20% lighter with all the same fire and sound rating.

Indeed

Me too. however, I would like to see those results tested by a credible third party. It's not clear that is the case.

> "We have the test results to prove that EcoSmart board maintains acoustical and fire-resistance properties compared to standard GWB but we can’t give you the secret.”

This is lame to the point where one shouldn't use it. They owe customers all of the data relating to performance (not just "meets specs" or "comparable") and what is in it (eg, some new fire retarding chemical with a limited safety track record?). Keeping their manufacturing process secret is fine.

I second this.

Are they saying they won't release the test results? Or rather are they saying that they won't say how their product is formulated to make it achieve these test results? Those are two quite different statements - and if it's the latter, why would we care?

Hi Malcolm.

It's the latter and it is very common. When researching products, manufacturers often withhold information from us, claiming it is proprietary or a trade secret. Sometimes it tough to even get them to confirm what is common knowledge about their materials. From their point of view, it's about competition; I think more consumers would feel comfortable buying products from manufacturers who are forthcoming with information and that transparency should be good for sales. But you are right, whether we know how a product is made or not, test results are necessary, either way.

Interesting. What's the difference compared to the Sheetrock Ultralight? It sounds like maybe fire rating, but in terms of environmentally--does the Ultralight have similar benefits?

Great question. USG makes an Ultralight Firecode X panel as well as the EcoSmart. I am checking on the difference(s) because from a quick check on USG website, don't know.

Peter

Gary -

From USG: "EcoSmart Panels are lighter than Ultralight. This product improves upon our existing Sheetrock Brand Ultralight Panels. So they handle, install and perform better than traditional wallboard, and...they are made using a more sustainable manufacturing process. EcoSmart Panels are the industry’s first and only sustainable, specifiable wallboard product. There is no difference in fire rating."

I asked how much lighter the EcoSmart board is than the Ultralight board and have not heard back. I THINK the difference is in the 10% range.

Peter

Follow up from USG:

"USG Sheetrock® Brand EcoSmart Panels Firecode® X (UL Type ULIX™) weigh 1.8 lb./sq. ft., or 72 lbs. per 4 x 10 panel (for example). Comparatively, USG Sheetrock® Brand UltraLight Panels Firecode® X (UL Type ULX) weigh 1.9 lb./sq. ft., or 76 lbs. for that same 4 x 10 panel.

There are even greater weight savings when you compare USG Sheetrock® Brand EcoSmart Panels Firecode® X (UL Type ULIX™) to Type C, which weigh 2.5 lb./sq. ft., or 100 lbs. per 4 x 10 panel."

Thanks Peter!

“[Deleted]”

Log in or create an account to post a comment.

Sign up Log in