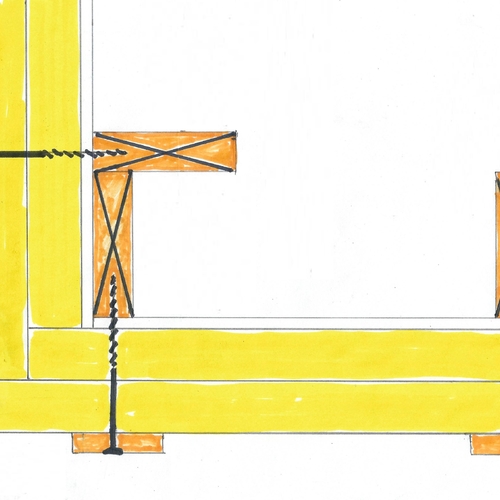

Image Credit: Image #1: Iso R Plus

There are two main ways of reducing thermal bridging through studs: you can build a double-stud wall, or you can install a continuous layer of rigid insulation on one side of the wall.

Most builders who install a continuous layer of rigid insulation use rigid foam (polyisocyanurate, expanded polystyrene, or extruded polystyrene); a small minority of builders use semi-rigid panels of mineral wool.

Builders who install rigid foam on the walls of a new building usually install the foam on the exterior side of the wall. There are several reasons for this:

- The exterior side of the wall has fewer interruptions (for example, electrical boxes and partition intersections), so it’s much easier to install an uninterrupted layer of insulation on the exterior than the interior.

- Exterior rigid foam is a good way to insulate rim joists.

- Exterior rigid foam helps keep wall sheathing warm and dry.

Unlike new home builders, remodelers can’t start with a blank slate. If a remodeler wants to reduce thermal bridging through studs, the exterior foam option is usually prohibitively expensive — especially if the siding is in good shape. So many remodelers ask, “Why can’t I put the rigid foam on the interior side of the wall?”

The answer is, you can.

Back to the 1980s…

In the 1980s, most cold-climate builders were taught that walls needed an interior vapor retarder, and needed to be able to dry to the exterior. When a few pioneers started installing exterior rigid foam, some people thought the practice was risky.

“Rigid foam is a vapor retarder, so it belongs on the interior,” some old-time builders opined. “Exterior rigid foam is risky, unless you live in Florida. It’s a wrong-side vapor barrier.”

Eventually, researchers proved that these builders were wrong. (To learn more about the history…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

51 Comments

Thanks

Thanks Martin for yet again summarizing another green building question so well.

You've got the following typo under What type of rigid foam is best?

"because XPS contains contains both"

Interior foam board seems like a great solution for remodeling dilemmas where exterior foam isn't a practical option, but I'm still unsure how the exterior should look, for this to be a safe assembly. I can think of my 1950's house with solid board sheathing, tar paper, and original wood shingles. This would seem safe enough, but this was all covered with 1/2" EPS, and wide plank color-lock siding. No rain screen gaps to encourage drying.

This is not uncommon for the older homes in my area to have several layers of siding accumulate over the years. Can you comment more on when interior foam shouldn't be used? When does the exterior stack up create too much risk?

Thanks!

Response to Mark Fredericks

Mark,

Thanks for catching the typo.

There is no simple answer to your question about exterior layers.

Unfaced EPS that is 1/2 inch thick is fairly vapor-permeable (about 4 to 12 perms), so that's not much of an issue. If the EPS has a plastic or foil facing, of course, the permeance could be much lower.

Multiple layers of wood-fiber products, even when painted, are also (usually) permeable enough not to cause problems.

If you install interior rigid foam, the interior foam layer reduces air leakage, and just about stops outward diffusion in the winter. That helps keep the wall assembly dryer.

As long as the wall isn't getting regularly soaked by wind-driven rain, and as long as the wall has good flashing, I wouldn't worry too much. If the sun hits the wall, the wall will dry. North walls (and walls shaded by foliage) tend to stay a little damp, however.

foam for furring out studs

Martin -- it's a little off the topic of your blog, but I wonder if you had an opinon on the method described by Stephen Bonfiglioli in the April issue of FHB, whereby he furred out the studs to the interior with foam to create a thermal break.

Response to David Hicks

David,

My first reaction to the idea of "Bonfiglioli strapping" is that this method seems quite labor-intensive.

But one thing I've learned over the years is: there is no way to discourage a builder who has found a technique that he or she is comfortable with. If Stephen Bonfiglioli likes his system, that's great. It works for him. That makes it a good system.

There are many, many ways to build a wall: the Mooney wall (2x6 wall with interior horizontal 2x4 strapping, all filled with cellulose), the double-stud wall, the Larsen truss wall, the Klingenberg wall, the wall with exterior foam, and the wall with interior foam. Now we can all consider the idea of Bonfiglioli strapping.

Choose a system you like, and build it.

.

vent

Martin, did you notice the vent stack on the exterior wall in the FHB article? That was surprising.

Response to R. Miller

I agree. Locating a DWV pipe in an exterior wall is usually a bad idea -- especially if you are an energy-conscious builder, and especially if the wall has no exterior rigid foam.

.

David

A few companies make thermally broken studs - rstud and Nordic Industries come to mind. They don't seem to have caught on. It would be interesting to compare their prices once you factor in Mr. Bonfiglioli's time to make his homemade versions.

Vapor barriers revisited

At first I thought this might be a cold climate only technique. But you mentioned that this technique is fine even in climates with inward solar vapor drive during the summer. After reading your articles on vapor barriers as well as Joe Lstiburek’s, I am slightly confused.

I’m assuming that all poly-iso panels are vapor barriers (Class I). In Joe's BSD-106 paper, figure 6 shows a brick veneer and typical 2x4 wall construction. My understanding is that the vapor barrier was eliminated from this wall by design. Are you saying that it is OK to add the poly-iso panels under the drywall in this type of wall?

Would this rigid foam technique be allowed for an unvented cathedral ceiling? That is could the poly-iso be placed between the drywall and the rafters with batt insulation between the rafters?

Thanks for this blog. Hopefully I will understand vapor barriers after this.

Links to Martin’s blogs and Joe’s paper:

Do I need a vapor retarder?

Insulated cathedral ceiling

Cut and cobble insulation

BSD-106 Understanding vapor barriers

Response to Steve Robertson

Steve,

I don't see any reason why you couldn't install rigid foam on the interior of the wall shown in Lstiburek's sketch. Because rigid foam has R-value, it isn't as dangerous as polyethylene. Air-conditioned poly can be a condensing surface, but the outward-facing layer of rigid foam wouldn't get as cold as the poly.

No, you can't install interior rigid foam on an unvented cathedral ceiling (unless you are following the cut-and-cobble technique, which I don't recommend). However, interior rigid foam is often used on vented cathedral ceilings.

For more information, see How to Build an Insulated Cathedral Ceiling.

polyiso board facing

Martin - can one use a fiber faced polyiso board rather than foil faced board - the fiber faced board is easier to obtain - (standard low slope roofing insulation)? Is this an air sealing issue?

Response to Roman Stankus

Roman,

Yes, you can use almost any type of rigid foam in this location, including polyiso with fiber facing. I don't have advice about the best tape to use, since I haven't ever had to tape this product. In my experience, however, you can tape almost anything with Siga Wigluv tape.

Moisture concerns about sandwiching interior plywood

Hi Martin -

I'm retrofitting a house in southern California with uninsulated stucco walls and no sheathing. My plan is to use the "sticks" in the stud bay corners method you describe to create an air gap behind the stucco/building paper and then cut and cobble polyiso in the 2x4 stud bays. So far so good I think. (Yes I am aware of the labor intensity of cut and cobble.)

But the structural engineer has specified that these need to now be shear walls since there is no shear bracing otherwise. So inboard of the studs will go 1/2" plywood. I'm concerned about thermal bridging through the studs and through the plywood, and some simulations I've done seem to substantiate these concerns. So I am considering adding another 1" of polyiso inboard of the plywood, then drywall, and affixing the drywall by running screws through the polyiso into the plywood/studs. (Do I need furring between the polyiso and drywall?)

Should I be concerned about sandwiching the plywood in between the interior continuous polyiso and the cut and cobbled polyiso in the stud bays? Will the studs provide sufficient pathway for any moisture in the plywood to get out? Thanks for your help.

Response to Chris Stratton

Chris,

I assume that you have read this article: Insulating Walls in an Old House With No Sheathing.

Q. "Should I be concerned about sandwiching the plywood in between the interior continuous polyiso and the cut and cobbled polyiso in the stud bays?"

A. I don't think there is much reason for concern. There shouldn't be much vapor drive through this wall assembly -- either inward vapor drive or outward vapor drive -- that might lead to moisture accumulation in the interior plywood sheathing.

That said, there is no reason to choose a very low-perm material if it isn't necessary. What type of polyiso are you talking about -- foil-faced polyiso or a fiber facer? For the interior layer of rigid foam, the best choice would be either polyiso with a fiber facer (not a foil facer) or EPS. These types of rigid foam are somewhat vapor-permeable.

-- Martin Holladay

response to Martin

Martin,

Yes I have read your article about insulating a house with no sheathing. It was very helpful. Thank you for writing and for referring me to it. I'll go with fiber-faced polyiso for the wall insulation, per your recommendation.

Thanks again,

Chris

Response to Christopher Merino

Christopher,

Q. "Does one need insulation in the wall cavity if installing foam board on the inside?"

A. No, there is no need for insulation in the wall cavity, as long as the insulation plan meets local code requirements. (In most cases, retrofitting insulation in an older home will not require compliance with modern energy codes, but regulations vary from town to town, so it's usually wise to call your local building office if you are uncertain of your local regulations.)

interior rigid foam

Does installing rigid foam insulation over interior wall studs negate the need for insulation in the wall cavities themselves? May they be disregarded?

interior foam plan and a service cavity?

Thanks for this excellent resource. I am currently remodeling an 1890s house in climate zone 6. My wall from exterior looks like this:

8" lap steel siding

15lb felt / original

original 1" x 6" horizontal sheathing

true 2x4 studs / balloon framing

Unfortunately, I did not consider installing insulation on the exterior when I resided a few years ago, so now my plan is to add this to the interior wall based on what I have read in multiple articles on this site.

air seal the interior of the walls in the joist bays

add insulation in the joist bays likely fiberglass or rock wool. R 13 likely

2" of polyiso board on the interior of the studs = R 12 total

2x strapping for both holding polyiso boards in place, attachment for interior wall coverings and to create an electrical chase.

Another option would be to simply build out the studs by 2" vertically and I could use the Roxul 2x6

R23 bats and then another 1 or 2" of polyiso on top.

By my math this would only give me an additional R2 (23 in wall + 2" rigid @ 12 total)

I am open to any feedback on this.

Also has anyone built an electrical service chase on top of the interior rigid foam? It seems that the strapping for wallboard could work perfectly as the framing for this service cavity as well.

Thanks in advance

Martin,

Not sure if this is still an active thread, but I am following up on a point you made stating this approach should not be used in a cathedral ceiling room. I am reinsulating several rooms with flash and batt approach (zone 5). These rooms are not vented. I would like to add rigid insulation to the underside of the roof to secure batts and reduce thermal bridging from rafters. Given your comment I am reconsidering this approach. Any guidance is greatly appreciated,

Ryan

Ryan,

For an unvented flash-and-batt roof assembly to be safe, you need to pay attention to the ratio rules.

A standard flash-and-batt job for a roof in Climate Zone 5 requires (according to most codes) that the closed-cell spray foam layer have a minimum R-value of R-20. That can be achieved with about 3.5 inches of closed-cell spray foam. (For more information, see "Flash-and-Batt Insulation.")

If you are adding more insulation on the interior side, though, the ratio changes. Note that the ratio rule (for a roof assembly in Climate Zone 5) is that a minimum of 41% of the total R-value of the roof assembly come from the outermost layer of air-impermeable foam insulation (which in your case would be the closed-cell spray foam that has already been installed).

For more information on the ratio rules, see "Combining Exterior Rigid Foam With Fluffy Insulation."

So you need to do some math to see how close to the borderline of the 41% minimum you're already at.

Martin,

Thank you for your response. I split r23 roxul batts and put over close cell foam to fill the bay, and intended to apply foam board over that to secure batts and help with thermal bridging. With batts plus board I would be within the 41% rule (50+ percent).

Based on feedback from another thread it appears I must use a relatively permeable layer to enclose the batts (unfaced EPS) due to the likely occurrence of condensation on interior closed cell foam. I have not been able to source unfaced EPS yet, and have started looking at other materials. If you have thoughts on this I would greatly appreciate it,

Ryan

Ryan,

As long as the rafters are dry when you install the interior rigid foam -- and there's no reason for me to think they'd be wet -- then there really isn't any downside to using interior rigid foam with a low permeance rating. Plenty of people successfully install foil-faced polyiso on the interior of cathedral ceilings.

Mr. Holladay,

Thank you so much for all your articles on these topics. They've helped me a great deal.

We're building a new home in zone 6 and I planned for 2 inches of exterior XPS and R-23 rockwool cavities. Our builder feels strongly we should do 1.5 inch foil-faced polyiso on the interior instead of exterior foam. His reasons are that it's hard to attach siding through foam, and pests (ants specifically) often nest in it. He recommends the same change for the basement (no exterior foam, all interior).

I've read several of your articles on walls and insulation and I'm concerned this moves our dewpoint to inside the stud cavity. We will have no exterior vapor-barrier so he says (and it looks like you agree in the article above) that it's OK if we have frost or condensation in the wall because it can dry to the outside during the summer.

I also have concerns about putting the walls (both stud and basement) outside the insulation envelope and therefor subjecting them to bigger temperature swings.

Do you have thoughts on doing interior foam in new construction like we are doing, as opposed to a remodel?

Martin,

Thank you for this informative piece on a somewhat difficult to research topic.

Im in the process of remodelling an old farm house and am currently working on a room that has no ductwork to it. I want to drop the wall that separates it from my kitchen so as to combine them and make one big kitchen. Right now this room is an energy suck, I'm hoping with better insulation I can remedy this. I ripped all the sheet rock off so I could see what kind of insulation was behind it (R7), rip it out and replace. I'd like to put R15 Rockwool batts bt the oak 2x4 studs and then go over it with foam board or rockwool rockboard for extra R. My interior wall covering is going to be 3/4" thick pine T&G.

My first question is do you think I need to fir out over the foam board being that Im using 3/4" pine instead of sheetrock, can I screw through the T&G/foam and into the studs? Besides my electrical getting buried behind the foam board (I'm going to use extendable boxes), do you foresee any issues?

Second, I'm drawn to the rockwool products for their fire retarding qualities. BUT I can't find it anywhere so I've never handled it. Is it rigid enough to go directly bt my T&G and the studs? If any of the various Rockwool boards (40/60/80/110, comfortboard) are, can you give me some guidance as to what you think is best?

Thank you so much Martin, I truly appreciate any advice you can give.

Breanna

Dear Martin,

I didn't notice any discussion about stone houses. I'm replacing windows in an 1850s farmhouse where the interior is framed with 2x4 walls. The 18" stuccoed stone openings for the windows are about 50 degrees in the winter (colder than the windows), so I'm considering covering them with foam board and 1/4" plywood. Make sense? If so, do I need 1" foam to make a significant improvement (since aesthetics matter)?

Thanks for your always helpful articles,

Mike

P.S. Sorry for photo turned 90 degrees.

Mike,

There is a wide range of possible responses to your problem -- from living with the current situation to ripping out the wall finishes and starting from scratch. It's hard to know how far to go.

From a thermal perspective, as I'm sure you know, a stone house is a disaster. It is best insulated on the exterior -- but if you do a good job, you'll never see the stone walls again (and many people like to see the stones).

I don't know whether your 2x4 walls are uninsulated or insulated. If insulated, I don't know what materials were used as insulation.

The problem with attempting to insulate a stone house from the interior is all the thermal bridges -- the floor joist areas, the partition intersections, and (clearly) the window penetrations. You've got a lot of very cold stonework in winter, and these thermal bridges are everywhere.

You can address the coldest areas, as you suggest, with thin rigid foam and plywood, but this approach isn't particularly effective (because the thermal bridges remain) and this approach is rather ugly. Whether it's worth pursuing is up to you.

Good stuff here. I’m finishing our basement and have Thermax 2.5” panels along the foundation wall on the interior that i’m Planning to install 1x3 strapping vertically 16” OC. Seems to make sense to be vertical as that’s what others will expect. Is horizontal better for reasons i’m Not considering?

Also, electrical boxes can be attached to the strapping with the Thermax carved out a bit to accept the box depth and then run the Rolex vertically along the strapping.

The house was built in 2011 and has a nice, dry basement.

Thanks again.

Wayne,

Q. "I’m planning to install 1x3 strapping vertically 16” OC. Seems to make sense to be vertical as that’s what others will expect. Is horizontal better for reasons I’m not considering?"

A. Either way -- vertical strapping or horizontal strapping -- will work. Depending on how you run the wiring, horizontal strapping sometimes makes more sense -- but if you plan to bring down your wiring to each box from the ceiling above, rather than to run any horizontal wiring, then vertical strapping is fine.

Martin,

It would be helpful if someone could clear up the requirements under US codes for protection of concealed wiring. Ours here in BC mandates a 1 1/4" clearance from the face of the stud when it penetrates it, or when it runs along side. I see a lot of installations on strapped ceilings and walls that seem to indicate that isn't the case down south, but it would be good for posters to know for sure.

Malcolm,

As a DIYer, I'm figuring this out from multiple sources!

While they (Tom Silva on TOH) don't talk about code, they do use 1x3s horizontally AND vertically to make a lattice for running wires and installing electrical boxes easier. I may decide to use up another 3/4" and do this. Comments start at ~8:28 minute mark. https://youtu.be/oKQdo88Ne74

Wayne

I've also been looking for clarification on this, specifically with strapped ceilings.

It appears the (potential) disagreement is whether the clearance applies to the entire plane, or if it only applies to the exact location of the framing (and strapping?).

It comes down to accessing the risk of homeowner actions and whether they will send metal into the ceiling in predictable or unpredictable ways.

I would love to run wiring in-between the strapping, but I do worry that a future owner will do something silly hanging something from the ceiling.

Malcolm,

The requirement for cable protection applies down here, too, at least where the NEC applies. If a cable is run through a bored hole in the stud, it must be held back 1-1/4", or it must be protected by a nail plate (NEC 300.4A). The same applies if the cable runs through a notch in the stud - a nail plate covers the cable and protects if from nail damage. But note that the part of the cable extending into space past the stud can still be closer than 1-1/4" to the surface. The idea is that people will be driving nails and screws into the stud and can't tell where the cable will be, so it needs protection. People shouldn't be driving nails away from the stud, so protection is not required.

This concept also extends to furred cavities (NEC 300.4D). If cables run parallel to the furring (perpendicular to the framing), they must be spaced at least 1-1/4" away from the furring, or they have to be protected by nail plates. The theory is that people are fastening the drywall and trim to the furring, not the spaces in between. So, if you keep the cables away from the furring, they should be OK.

For a basement wall with continuous insulation and furring on top, the same would apply. Cables running parallel to the furring should be kept 1-1/4" away from the furring. If the cable runs through a notch or gap in the furring, it should be protected by a nail plate just like if it was running through a notch in the face of a stud.

Peter,

Our code extends the need for mechanical protection, or adequate distance back from the face of framing , to wires attached to the sides of studs. Where things get complicated is we also have a requirement that where wires enter boxes they need to have a support ( a staple) within 12", and more supports at frequent intervals. What is that support attached to? You can't just run the wires between the strapping down the walls and into the box.

Considering the following wall assembly for lower zone 5 (southern Pa.):

Vinyl siding

Tyvek drainwrap

1/2 inch cdx taped

2x4s 16 inches oc

R15 fiberglass batts

2 inches polyiso (foil side in)

2x4s 18 inches on center horizontally (9 foot ceilings)

Drywall

Primary air sealing would be at the sheathing.The batts would be uninterrupted in their bays. The polyiso would be installed from the deck and taped and sealed . The horizontal 2x4s would provide a chase and the airspace would add additional r value generated by the foil facing. This assembly uses fewer studs than a double stud wall and avoids the difficulty of finding someone capable of dense packing . R30 or so seems more cost effective for zone 5 today/ maybe zone 4 tomorrow.

Please Tell me what I need to be concerned about.

Thanks.

Brad,

Not so much concerns as things to think through:

- The framing at corners and interior partitions to provide backing for the strapping over the foam. If you want the foam to be continuous you will need to frame interior walls afterwards.

- Think through your sequence of construction. You are going to have to insulate the cavities, then install the foam, etc. Pay particular attention to wall penetrations for services, which will be inaccessible.

- 1 1/2" strapping means using different electric boxes. watch for fill limits, or use 4" boxes with mud rings. Also see my comment #32 above.

- 9ft ceilings are typically done with 4ft and 5ft drywall sheets hung horizontally. 18" spacing on the strapping doesn't give you backing at that joint.

I was thinking two 54

inch drywall panels. Corner detail would involve 1/2 x 6 inch ply backer boards screwed to the two stud corners. Shallow electrical boxes in the utility chase.

That would work, although you don't end up with a recessed edge at the ceiling, and there a lot more cutting.

As to construction sequencing, my assumption was clean , uninterrupted batt installation would lend itself to unskilled (homeowner/me?) installation. Too ambitious?!

No, sounds like a good idea. A lot depends on who is doing what. If you have a framing crew coming in, they would much rather get everything done at once. If you are framing the interior walls and strapping, no one can complain (except maybe you).

As to interior partitions, they would be studded out from horizontal 2x4s and would function as third level air sealing.

Sequencing was my main concern.

Thanks.

The sequencing is made much simpler by the continuous cavity. If you were just putting a layer of foam on the inside of the walls and screwing the drywall though it, the sequencing of things like roughing in the electrical would be a nightmare.

That's in large part why drywalling the ceiling before the interior partitions go in hasn't caught on. Great for air-sealing, a huge hassle for everything else.

My intention would be to sheath the bottom of the trusses with taped osb and 2x4 Nailers to provide a ceiling chase as well.

Good plan, but run both chases by y0ur inspector. See my posts #28 and #32.

Hello,

In our old 1924 shoebox house in Zone5, our current wall assembly is (from exterior to interior)

-Brick

-Cavity

-Tar paper (very thick stuff, almost cartonish)

-2" x 12" horizontal lumber (huge, old timber, not 2" x 12" from Home Depot)

-Another Tar paper

-1" x 6" tongue and groove vertical planks

-3/4" furring, 16" spaced

-plaster and latte

So far, we removed the plaster & latte and the furring, and our idea was to go with this assembly:

-Brick (untouched)

-Tar paper (untouched)

-2" x 12" horizontal planks (untouched)

-2nd Tar paper (untouched)

-3/4" x 6" tongue and groove vertical planks (untouched)

-7/16" OSB in 4' X 8', PL glued and fixed with screws long enough to reach the 2x12 (this to plumb the whole wall surface and give back a bit of bracing stiffness that might have been lost by removing the dense plaster & latte). >>>. UNNECESSARY?

-2 X 1-7/8" EPS ISOLOFOAM HD 160 (staggered) as one continuous layer (total = 3 3/4" - R15.1)(https://isolofoam.com/wp-content/uploads/2019/10/Isolofoam_HD160_TDS_EN_2016-07_1.6.pdf)

-vapor barrier / reflective barrier (https://www.resisto.ca/en/product/iflex-1928/). >>>

UNNECESSARY?

-1"x4" furring

-5/8" fireX gypsum.

Is that seem like a general good assembly considering our limited insulation options situation? We understand our walls will get thicker by almost 4" and can live with that. Any omission or unnecessary steps in there?

thank you

I'm restoring a 1850s 1.5 story farmhouse in northern Vermont. I'm insulating the slanted ceilings on the second story with cellulose. I'd also like to add 2" of rigid insulation inside the room on that slanted ceiling. I'm wondering if mineral wool could work rather than EPS? Here's my assembly from outside to inside-- blown in cellulose in existing studs, Intello, Roxul Comfortboard, strapping, drywall. Does this seem safe?

User 7523812,

Q. "Does this seem safe?"

A. Yes, that seems safe. By the way, the framing members that you are calling "studs" are actually rafters. For more information, see these two articles:

"How to Build an Insulated Cathedral Ceiling"

"Insulating a Cape Cod House"

Block walls and slab?

We've acquired a very small block building on a slab, and it needs basically everything. 18x38 total, it will be a 1/1 house. Bare block/some old paint, looks like block on a foundation with the slab poured inside (there are small vertical gaps around the edges, obviously the slab isn't turned down as a wall foundation). No insulation at all right now. Zone 3, eastern NC but not quite coastal. All current partition walls are coming out and a few different ones will be added. Load bearing only at exterior walls.

Ceiling/attic will be R 40ish cellulose with some blocking at the eaves for wind washing, seems like the most straightforward bit. Partition walls will all be completely inside the foam envelope.

Although nothing's purchased yet, the plan is 1-1.5" foam board on the floor with floating double OSB or ply floor (balancing comfort with ceiling height), 2" foam (foil faced, taped polyiso) on the walls with furring and drywall (electrical maybe in pvc conduit in channels behind foam).

I've done a bunch of reading, but I have a couple of questions I can't find anything definitive on, and I'd love some thoughts.

1) Could I use polyiso in the floor, despite the relatively low chance the slab has a moisture barrier? If so, should I put 6 mil under it? Or try to do the gymnastics of taping the underside? Or should I just take the slight cost and R value hit for EPS?

2) When painting the exterior block, would the second moisture barrier of regular paint be ok? Or should we only use a mineral paint to allow the block to dry outward?

Thank you in advance!

Jon Best

Hi Martin, I wanted to revisit this topic of placing continuous insulation on the interior. I’m looking to make a living space in upstairs of already built garage. Currently, the garage has 2x6 walls covered by Zip System sheathing, furring strips and cedar siding. I plan to put Roxul batts in 2x 6 cavities. Can I add 3” thick Roxul Comfortboard on interior? Assume I would want Intello Plus membrane inside of that behind drywall? Any feedback on this plan and help avoiding moisture or air quality problems appreciated. Thanks.

SP,

Roxul Comfortboard is semi-rigid. If you plan to finish your walls on the interior, you need something to screw the drywall to. In theory, you could try to use 4.5-inch screws to attach the drywall through the Roxul Comfortboard to the studs, but I don't think that would work -- the Comfortboard is too squishy.

You might consider the Mooney Wall approach (Google it), with the horizontal framing members over the Comfortboard (or even a system where the Comfortboard -- probably a lesser thickness of Comfortboard -- is installed between the horizontal framing members).

But this all sounds complicated. Maybe you just want a double-stud wall.

We have a third story space that is part knee wall, part slope, part horizontal ceiling. All lath/plaster. No insulation in the house at all. Could we apply rigid foam directly over the existing plaster? Certainly don't want to gut the space...

Whos,

Yes, you could do that. But unless you have a continuous air barrier (including your basement, first floor, and second floor -- with all intersections addressed) and a continuous layer of thermal insulation (again, including your basement, first floor and second floor -- with all intersections addressed), your house will have so many thermal bypasses that the value of your efforts is questionable.

The other issue, of course, is that internal rigid foam will lower your ceiling height.

Log in or become a member to post a comment.

Sign up Log in