Condensation problems in hot humid climate — non-vented metal roof?

I am building a 2-story wood frame house in Central Florida. The building department will not allow me to use spacers under the metal roof clips to add above-sheathing ventilation for a non-vented roof assembly. My goal is to minimize heat gain into the conditioned space.

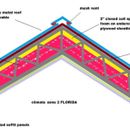

My worry is that the 24-gauge Galvalume metal roof directly on top of the sheathing and vapor permeable underlayment won’t have adequate ability to dry out due to minimal air space and thus condensation may be an issue for roof longevity. (See diagram for proposed assembly).

Am I worrying about nothing, or should I switch to a vented assembly?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Raymond,

You are building an unvented flash-and-batt roof. The roof should work.

I'm not sure why your building department won't allow "spacers" (although I'm also unsure what type of "spacers" you are talking about). Perhaps there are structural concerns related to high-wind codes?

Even without the "spacers," your roof should perform well.

Could it be a fire code? Some municipalities in the SW won't allow vented roofs.

Thank you for responding - I am glad to receive some confirmation that the design is sound before moving forward. Florida inadvertently limits innovative building techniques after instituting required Florida Product Approval for items such as roofing, fasteners, doors, and windows. Thus, I must follow the manufacturer's installation guidelines exactly as tested to obtain building dept. approval.

Jon,

Great idea about using the foam backer rod. I will use 3/8" diameter rod after also reading about the advantages of minimizing oil-canning using this technique (link is : https://www.danperkinsroof.com/pdf/backer-rods.pdf)

I'd look into putting foam backer rods under the roofing. It won't provide significant heat reduction, but it can (full length, with end vents) provide significant (as compared to the wetting rate from inside) drying.

Use high Solar Reflectance Index roofing to minimize heat gain

Jon,

Here we go again. Where is there any evidence that a backer rod in the middle of the panel will provide significant drying? And how would you provide "end vents" at the drip edge?

Raymond,

I'm not saying it isn't a good idea for oil-canning.