Detail and Insulation Review

We are looking to do REMOTE wall construction on our new house located in S.E. Michigan. Currently drawn as 2″ exterior rigid foam, but 3″ will probably be the the correct amount to use. I plan to use Bituthene as the WRB, not sure if anyone can recommend any alternatives? I really like Bituthene’s low perms and low cost, but I assume that asphalt products aren’t all that green….

We have been quoted on Superior Walls (http://www.superiorwalls.com/). We are waiting on a quote for ICF. However, I think that if I am going through the trouble of wrapping the house in Bituthene and rigid foam, shouldn’t I just have a traditionally poured basement and continue the outsulation and wrap down to the foundation?

We plan to use Hambro D500 (http://tinyurl.com/hambro1381) w/ concrete slabs and radiant heat.

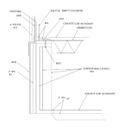

Taking any other comments, concerns, and recommendations on the attached section.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You may be pleasantly surprised ( or stunned and annoyed) at the cost of ICF. Even if it costs a bit more up front, there is usually a time-is-money factor to consider. Competent ICF installers can get you there on a shorter schedule, than a post-applied out-sulation approach, which can sometimes be a significant (if somewhat hidden) cost saver in the end.

Whatever you do, be sure to put a capillary break between the footing & foundation wall, which can otherwise become a real source of basement dampeness in an ICF or out-sulation basement.

The other advantage to ICF over out-sulation on basements is that the slab-foam can butt up to the interior foam of the ICF, thermally breaking the otherwise significant thermal bridge to the footing & subsoil.

Thanks for the reply Dana.

As for the WRB coming down off the sheathing, is it OK to wrap ICF?

Eric,

You can't use polyiso insulation on the exterior of a concrete basement wall because polyiso absorbs water. Bituthene (otherwise known as peel-and-stick or rubberized asphalt membrane) won't necessarily keep your polyiso dry. The only types of insulation that work in this location are EPS, XPS, or closed-cell spray polyurethane foam.

If you plan to put the polyiso on the interior, that would work.

More information here: How to Insulate a Basement Wall.

[P.S. If GBA readers notice that this answer doesn't correspond to the question, that's because the original poster edited the title and text of the question after I answered.]

Thanks Martin,

Edit: Please see revised Topic, Question, and Section Detail

Eric,

Your sketch shows an above-grade wall with R-13 insulation. In your climate zone (zone 5), the 2009 IRC requires a minimum of R-20. Even 3 inches of polyiso barely meets code (sort of -- not really).

I strongly urge you to install at least R-30 wall insulation.

At 3" continuous polyiso would meet code for Zone 5 (really!) at about R18-19, but 2" would be a bit shy at R12-R13.

IRC 2009 requires R20 center-cavity on 2x6 construction, or R13 center-cavity 2x4 with R5 continuous insulation on the exterior, either of which runs about R13.5-R14 whole-wall, with the thermal bridging of the framing factored in at typical framing fractions. R18 continuous insulation (3" iso) would beat that with some margin, R13 (2" iso) wouldn't quite get there.

Filling the 2x4 stud bays marked "empty" with cellulose would bring the wall assembly well above code-min, at a whole-wall performance of ~R20-R22 after the thermal bridging of the framing is factored in. But there's both a comfort & economic argument for going higher. Bumping up to 2x6 24" o.c. with a 20% framing fraction and cellulose cavity fill with 2" of exterior iso you'd be at ~R27 without a big upcharge on either the framing or the insulation.

So 30 on upper wall and 30 on basement?

Also would Roxul Batts or open cell spray foam on the interior suffice ie are you talking total wall insulation? Thanks again.

Dana,

I doubt whether a local code inspector would agree with your claim that R-18 + R-0 satisfies the code requirement for either R-20 or R-13 + R-5. But it would be fun to sit on the sidelines and watch you try to convince the inspector. You never know -- you might succeed.

Remember, the code is not about logic.

I suppose Eric could always comply with the code by following one of the performance paths instead of the prescriptive path.

I found some DOW TUFF-R 1.5" sheets at R9.8. Three of those should do it for 4.5".

Can you recommend R Values for basement and unvented roof?

Also any other products than Bituthene?

Eric,

I assume that you have read my article on PERSIST construction? Here is the link: Getting Insulation Out of Your Walls and Ceilings.

There are lots of alternative products that you can use as an interior air barrier / WRB for a PERSIST wall. One option is a liquid-applied WRB: Housewrap in a Can: Liquid-Applied WRBs.

Other builders have used taped housewrap in this location, although it's unlikely that taped housewrap would be as airtight as the other alternatives.

I have read your articles and found them very informative.

I plan on doing a vapor impermeable wrap around the house. I have looked into Pactiv RainGuard and SOLITEX MENTO, neither compare to the vapor permeability of Bituthene. The WRB-in-a-can is interesting and I will look into it, but I feel that a peel and stick may be something I can apply myself. Airtight tape will not give me the vapor impermeable barrier I was looking for.

Having a fully sealed house has lead me to figure out an adequate mechanical ventilation system inside. It will most likely be a whole house ventilated dehumidifier (Ultra-Aire XT155H). We selected a dehumidifier because there won't be a ton of energy (based on our HVAC*) for an HRV/ERV to recoup, also they don't manage humidity. *We plan on passing on AC at this time (and if we do add it will be a mini-split) and heating our radiant floors with a gassifying wood boiler.

Also to answer my previous question, I plan on following the R Values outlined here:

BuildingScience.com - High R Value Walls

Eric, I too am building in SE Michigan. What have you decided to do with regard to the shell construction? Were you, in fact, stunned by the ICF quotes (and by whom)? The more I read about ICFs (and I did my basement with them 12 years ago), the more I'm inclined to believe a 2x6 wall with many layers of XPS on the exterior is less expensive.

Hi Lisa. We got the quote for ICF and it ended up being a little more than our Superior Wall quote. We plan on going with Superior and a PERSIST wall construction.

I actually came here to post my roof section....

I have been trying to figure out a large roof overhang while maintaining the insulated shell of the structure. Please see attached sections.

I am a little wary of the structural capabilities of the ladder eaves, but using 2x4 furring strips (metal) or plywood/OSB (shingle) under our roofing should allow us to tie together the eaves nicely. I plan on offsetting the 2x12 connecting plate into the foam to act as furring and an attachment point low enough to hit the rafter blocking.

This is hopefully the last major detail I need help with before I can finalize the full section. Please leave questions, comments, and concerns.

Thanks,

Eric

Just realized I had 7" of Polyiso. Here is what it would look like with 9"

so your polyiso is acting as the WRB too? R-24 in walls and 58ish at roof? I saw an article about a builder in A2 who was using Superior walls. I contacted him and he loves them. It's certainly unconventional with no footings.

We've used Superior walls on a couple of projects and haven't had any problems. Especially this time of year they really make things go faster. IMHO they don't make much sense for an unfinished basement, but they are much more cost effective for a finished basement than conventionally formed walls. They claim because of the high PSI of the concrete that no dampproofing is needed, but we've felt it was a small insurance policy to add bituminous dampproofing.

Eric, did you build with Hambro after all? I would like more info if you did.