Drill lookout framing for soffit ventilation?

I’m currently installing insulation baffles in a mostly new build (kept old basement, but completely gutted main floor and added 2nd story).

I’ve attached some pictures to help explain.

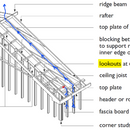

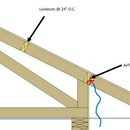

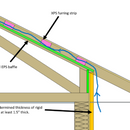

We have some fairly standard raised heel roof trusses, soffit & ridge peak venting, and 2 foot overhangs at the eaves and gable ends. To support the wide overhangs, the trusses have “lookouts” (see diagram-1). The lookouts are fine, but block the airflow from the soffits (see diagram-2). This is only a problem in the corners of the roof. Everywhere else, I’m venting with a 2″ air channel (diagram-3).

How do greenish builders vent in the corners with the lookouts in the way? I’m currently thinking of drilling a few 1/2″ holes in each lookout to allow for a bit of air flow.

I’m in chilly Winnipeg Manitoba Canada.

Thanks for your help.

Adam

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Adam,

At this point, drilling a few holes is probably the best approach -- or using a Sawzall to make deep notches. Don't overdo the notching -- the lookouts have to hold the snow load.

When in doubt, reinforce the lookout with perforated steel strapping.

Adam,

Unlike cathedral roofs framed with rafters, the path of ventilation from soffits to ridge on a trussed roof is not as direct. Often only some of the truss bays are open at the bottom, and roof vents spotted along the top are commonly used instead of ridge vents. The area is one big plenum. as long as adequate levels of ventilation are provided for it isn't important that each truss bay has access at the soffits.

I build in the PNW where even well-ventilated and air-sealed roofs often show a bit of discolouration on the underside of the sheathing. Having spent a fair amount of time working on houses built this way, I've never seen any difference in the moisture damage to the sheathing where there are lookouts blocking airflow and the other parts of the trussed attic.

Unfortunately, drilling holes into or notching a 2x4 used like a joist appears to be a building code violation (in Canada see https://www.cmhc-schl.gc.ca/odpub/pdf/61010.pdf chapter 19, else http://tinyurl.com/stackex-holes). That said, I doubt that I would ever actually have structural problems with a few 1/2" holes spaced appropriately. I also wouldn't be venting much either with a few small holes.

Another possibility I hadn't considered before is to drop the insulation baffles to below the look outs (see diagram 4). I would probably go with the minimum 1" air space and then likely beef up the outer insulation with blocks of XPS to account for lost R value with the decreased room for cellulose. Diagram 4 shows what should give me R50+.

Martin: good advice on steel reinforcement if I go the drilling route.

Malcom: thanks for sharing your experience. Good to know that it should be fine if I decide to just leave the corners unvented.

I really appreciate the GBA community. Most contractors/people I talk to in person have no interest in exceeding minimum code requirements or whatever the busy building inspector will pass.

P.S. I'm still trying to decide whether it makes sense to go R70 in the attic as my house uses fairly standard building practices and will only have R22 on the main floor (R14 in 2x4 wall + 2" exterior rigid Roxul). The second floor will have R30 insulation (R22 in 2x6 wall + 2" exterior rigid Roxul).

Adam

* Edit to attach file.

Adam,

Build a quick spreadsheet and change the R value from 38 to 70 for your ceilings and see the overall change in heating requirements. If this allows for sizing the system smaller you will see savings instantly. For my model it made sense for me to go from R20ish to R60 because I was blowing the cellulose myself. At the installers price it would have been a longer payback.

I would think your XPS sandwich would work well, it would just take some time to build a bunch.

I like your concept in the picture in comment number 3. I wouldn't bother with the stack of XPS blocks--just by having a raised heel truss you are much better off than most of the houses out there. If you do feel compelled to put a stack of foam there, "greenish" builders avoid XPS because it's made with a blowing agent that is 1400X worse for global warming than CO2. EPS and polyiso are much, much better choices in that regard.

If you opt to provide air flow through the lookouts, drilling in the center is probably better than notching. Figuring out how code applies to something that isn't really a stud, a rafter, a joist, or a plate is not likely to be straightforward, so you might need to check with your code official. I would think maybe 3 holes, each 3/4" diameter, spaced 1.5" apart, but that's just seat-of-the-pants, not engineering or code based.