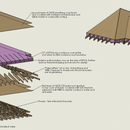

Exterior Insulation for Stacked Hip Roof

Hi,

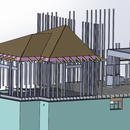

I am working my way through a deep energy retrofit on my 1908 home located in Bellingham, Wa (4c). My end goal is to be near passive level performance. One section of the house is being entirely re-built, so I want to take the opportunity to apply some bomb-proof details – with a particular focus on the impossible-to-vent stacked hip roof (see attached screenshot). I am leaning strongly towards an unvented assembly, and am trying to avoid sprayfoam. Thus, I am thinking of moving all the insulation for that roof exterior of the roof deck (and primary air-barrier). Essentially what is described in this article:

I am trying to convince myself and the building department that this is both a good (and code compliant) approach. But wanted to run a couple of questions by the community –

Q: In the above article it suggests one option of balancing some of the total insulation value on the inside between the rafter bays. My initial thought was that having “loose” (say mineral wool) insulation would provide little resistance to interior moisture reaching the now slightly cooler backside of the roof sheathing. So would it not be more optimal to move all the insulation to the exterior?

Q: In the attached screenshot I have an initial u-factor calculation for the required depth of insulation. Using the parallel path method I came up with .023 using 8″ of polyiso, which seems like it would meet or exceed the code required .026. Any advice on using this u-factor calculation differently, or practical reason to go with more foam? Trying to balance foam depth with ease of installation.

Q: After talking with the building department, the initial concern they mentioned was a risk of condensation on the bottom layer of sheathing. The interior sheathing will be inside of the primary WRB / air barrier which is also integrated with the adjacent wall WRB. The exterior foam seams would be sprayfoam filled and taped with Siga Wigluv. Does condensation on this interior sheathing layer seem like a possibility? Since the enclosed attic area would become part of the thermal envelope I would imagine that any condensation would be able to dry to the interior.

Q: Since the original issue with this roof was venting, I assume that adding vent channels above the foam is out of the cards. Is that a deal-breaker for this design approach, or is there some documented success with leaving this assembly un-vented?

Any input or related articles would be much appreciated.

For some added background here is a rough list of what has been done thus far on the house:

-Lifted the house and added a new Nudura ICF basement and slab with 6″ of eps below.

-Lowered the house back down on new mud sills with high performance gaskets with a healthy dose of sealant above and below.

– New first-floor rim boards with lots of sealant top and bottom.

– New first floor walls to replace rotted bottom plates with all joints again packed with sealant.

– All new cdx sheathing sealed on backside to all studs, headers and plates. All seams will be taped.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Bump. Any input appreciated!

Beth,

I was researching rigid foam on a hip roof and came across your question. It's probably too late for your project, but I'll give it another bump to see if we can secure any input.