Mineral wool in double stud wall (and others)?

Hi All,

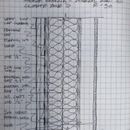

I am building a house in central VT (climate zone 6) and am liking several of the properties of mineral wool. Chiefly, since I’m DIY’ing, the cost is attractive. I have two wall sections in mind for this for which I’ve attached sketches below. So, on to my questions:

1. Double stud wall with mineral wool batts

This achieves R-30 with 2 layers of 3.5″ mineral wool batts

The interior stud wall is structural and is also a service cavity

Usually, it seems as though people are shooting for more like R-40 with these double stud walls so I’m unsure if the lower R-value I’m showing here would cause any problems (i.e. moving the dew point to an undesirable location inside the assembly)?

Also, people seem to always do this with cellulose or fiberglass… I haven’t seen anyone do this with mineral wool. Conceptually, I can’t see any problems so I wonder if it’s just because it’s a newer material?

2. Single stud wall with exterior insulation

This achieves R-31 with an exterior layer of mineral wool board @ 2″ and an interior layer of mineral wool batt at 5.5″.

I think this assembly is a good one but I wonder about the R8+R23 (continuous insulation + cavity insulation) that we have here when the VT energy code specifies R10+R15? I suspect that the R10 number they have has to do with controlling the dew point within the assembly… but I’m not totally sure what that’s about. Maybe a good question for Efficiency VT….

Finally, are we creating a moisture trap by sheathing both sides of the studs with OSB in this version? I’ve read that OSB can act as a “smart” vapor control layer, but I wonder if we’d actually need Intello or MemBrain instead there… I initially like the OSB for it’s durability.

I’m a firm believer in the concept of the service cavity and isolating thermal insulation and air and moisture control from all of the penetrations and interruptions that go along with plumbing, wiring, and mechanical, which is why that’s in both versions. Just seems to make good sense.

Thanks to anyone with the patience to read through all that and even more to anyone who posts answers. GBA is such a great resource for DIYers and pros alike. I know some of these topics have been touched on in other threads but I felt that these questions were unique enough that they were worth posting.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jesse,

Let me make a couple of comments on the double stud wall.

I'm not sure there is any real benefit to having to build three walls over that you would achieve if you eliminated the middle one and insulated your service cavity. Your OSB layer would remain where it is, so you still would have no penetrations in your air barrier. You would lose very little insulation value to services.

From a practical point of view building three walls, which have to aligned at their very deep openings, is a large increase in the cost and complexity of the exterior.

I'd also like to see a section that showed the continuity of the load-bearing wall at the foundation and second floor (if there is one). It is fairly far back from the exterior plane and might cause some real complications to support.

Hi Jesse,

I too am a strong believer in a "service cavity" to protect the air barrier, BUT! I see no reason that the service cavity cannot be insulated with another mineral wool bat, adding r15 in the cavity and bringing an 11" wall up near r40. Do you have a reason for leaving the service cavity uninsulated?

I can't be sure, reading the sketch, if you have sheathing on the outer face of the inner wall. This is where the OSB is "safe" as it is relatively warm and can be well sealed to become the primary air barrier. The OSB on the outside is, I feel, risky and best omitted entirely or changed to fiberboard or "Denseglass" (either of which has much more desirable moisture permeability)

Jesse,

Q. "I'm unsure if the lower R-value I'm showing here would cause any problems (i.e. moving the dew point to an undesirable location inside the assembly)?"

A. No, it wouldn't cause any problems.

Q. "Also, people seem to always do this with cellulose or fiberglass. I haven't seen anyone do this with mineral wool. Conceptually, I can't see any problems so I wonder if it's just because it's a newer material?"

A. Cellulose has less embodied energy than mineral wool batts, and it does a better job of filling all the nooks and crannies of a wall assembly.

Q. "I wonder about the R8+R23 (continuous insulation + cavity insulation) that we have here when the VT energy code specifies R10+R15?"

A. I can't imagine that you will have any code compliance problems with this wall, especially since residential building codes in Vermont are unenforced.

Q. "I suspect that the R-10 number they have has to do with controlling the dew point within the assembly."

A. No, it's the opposite -- the R-10 code requirement is there in spite of the fact that it's the wrong number for dew point control. To read more about this issue, see The 2012 Code Encourages Risky Wall Strategies. In your case, however, you don't have to worry -- because exterior mineral wool is vapor-permeable, so it won't trap moisture.

A. "Finally, are we creating a moisture trap by sheathing both sides of the studs with OSB in this version?"

Q. In the first of your two proposals, the exterior OSB is at risk of moisture accumulation during the late winter. Whether you should worry about that fact depends on your perspective and your tolerance for risk. For more information on this issue, see How Risky Is Cold OSB Wall Sheathing?

Martin says,

"A. Cellulose has less embodied energy than mineral wool batts, and it does a better job of filling all the nooks and crannies of a wall assembly."

This is indeed a good answer to why cellulose is usually used. It also retards large-scale convection loops better and does a bit to reduce infiltration, although these benefits are often overstated.

But I think the "does a better job of filling all the nooks and crannies" can also be overstated. Regardless of what insulation material you use, you really need an installer to take responsibility for filling all the nooks and crannies. Cellulose does tend to get into a lot of them without as much explicit effort as is needed with batts, but it's still a job that requires skill and practice to do well, particularly for a deep wall. A meticulous job with batts could easily beat a sloppy cellulose fill. We've heard reports here of success with DIY dense pack cellulose, but batts might be more straightforward, particularly if you are working alone. In either case the difference between a sloppy job and a really good job matters so read up on doing it right.

The OSB is a class-II vapor retarder when dry, which is part of the problem, since it's on the "wrong" side of the assembly for a cold climate. Since the interior studwall is structural, putting the OSB on the exterior side of the interior studs would be the right location, and you could use a non-structural more vapor permeable on the exterior. (Exterior grade gypsum sheathing such as GP DensGlass or even a structural ~15 perm fiberboard something.) With the 0.5-1 perm OSB halfway into the total R it's average temp would be above the ~35-40F dew point of the interior air and would limit the amount of moisture going into the colder half of the assembly. That's enough for a zone 6 climate like VT.

With only R8 on the outside of R23 in zone 7 the sheathing would be at risk of accumulating moisture if there were no interior side vapor retarder, but with air-tight OSB on the interior side you already have a "smart" class-II vapor retarder on the interior side of the assembly. The exterior OSB dries to the exterior just fine through 2" rock wook, and the interior side OSB doesn't let any more moisture into the cavity than MemBrain would. That's a pretty robust stackup in any climate.

Looks like you borrowed a technique from Greg La Vardera with a 2x3 service on the interior side of the vapor retarder for running all the power etc. In your climate & stackup it's safe to insulate the service cavity with R8s (or compressed R13s, which would perform at R10) under the gypsum. You would have R31-R32 of insulation + OSB between the inner OSB and the colder outdoors. That puts the inner OSB only ~25% out from the interior temp, so it's temperature would average WELL above the dew point interior air dew point in winter, and would not take on enough moisture to become significantly more vapor open. Being somewhat cooler than the interior the RH of the proximate air on the conditioned space side of the interior OSB would raise it's permeance some, but the air in the cavity will be much lower RH, with it's dew point tracking the temp of the exterior OSB, which keeps the interior layer of OSB more vapor tight. It'll do just fine with the service cavity insulated as well.

Greg La Vardera uses membrane type smart vapor retarders his walls, with R6 in a 1.5" deep service chase. The primary difference in your stackup is that you are using OSB as the smart vapor retarder, which is just fine, and a 2.5" /R8-R10 service chase. Here's a picture of his favored stackup:

http://www.lamidesign.com/blog/imgs/best_2x6s.jpg

This works.

Thanks so much everyone for taking the time to respond to this.

@Malcom: I didn't label that drawing properly of the double stud wall. I meant to show an insulated cavity between the 2x4 leaves not a third stud wall. But your point is well taken. So for bridging I suppose you'd offset the studs in the 2 leaves? Also, yes sill and head details are not worked out yet.

@Jerry: Yes I was trying to show an OSB layer on the outside of the inner wall as a vapor control layer... point taken about the exterior OSB. I had read about it being risky in some of the other double stud wall threads on GBA, and was particularly interested on whether a lower R-value than is normal would heighten the risk! The primary reason for not including a third layer of mineral wool is cost. If we were getting a loan, I would absolutely do it, but we are financing the house ourselves so... I'm not sure I've ever even seen fiber board but it looks like something I'll have to research. I have worked with DensGlass before and it is not for me.

@Martin: Thanks for taking the time to respond! I'll read those other articles. Very interesting that the R-10 is not related to dew-point. It is strange that the energy code here is self-cert... But we're thinking that we'd like to go through the steps to get certified, perhaps through Efficiency VT. I notice that you are a Vermonter as well, how do you feel about their programs, if you don't mind?

@Charlie: Thanks for the input. I'll be doing the install and working alone. As I've mentioned the primary reason for choosing mineral wool over cellulose is cost because I just don't feel comfortable trying to do blown in myself, whereas I have enough carpentry experience to handle the wool, I think.

@Dana: Wow! Thanks for the elaborate response and analysis. I am aware of La Verdara's wall design, and I like it ,so I was borrowing that... I was reading an article of his earlier on GBA that really seemed to devolve in the comments section so I had my fingers crossed that it wouldn't happen again here. I'll have to look into this "fiberboard"... My main concern about smart vapor retarders is their durability. On the other hand, is there any data on the lifespan of the tapes and caulkings used to air seal an interior OSB layer? I wonder how long it stays sealed, actually...

Thanks again to everyone for taking the time and posting responses. It's so helpful to be able to access all of your knowledge.

Jesse,

The easy way to air seal OSB sheathing on the outer face of the inner wall is to " run a bead" of acoustic sealant on the studs and plates BEFORE the sheathing is laid on them and nailed out..Along with either gaskets or more acoustic sealant under the bottom plate, in corners and over the top plate to the ceiling air barrier.. Acoustic sealant is proven durable! To my way of thinking tape on the outer face is simply not needed The downside is you'll have to be there when the walls are framed, to be sure the sealant is actually used.. Will you be framing 16" OC or 24"? .You might consider Greenguard DC10 over high permeability house wrap as an alternative sheathing on the outer studs. Greenguard DC10 is a deeply textured fan fold XPS intended as a drainage plane usually used under "reservoir" types of cladding (like the thin brick I'm using).

Jesse,

You labelled it just fine, the mistake was mine. looking at it now i've no idea why I thought the gap was another wall.

Acoustic sealant works, but be warned--the usual acoustic sealant stinks for months after installation. I like Contega HF from 475 as a less stinky and presumably healthier alternative.

Jerry,

The problem with relying on sealant, rather than tape, is that it means you have to run your sheathing vertically and can't have walls higher that eight feet, unless you are going to block between the studs.

Hmmm... interesting. I'll have to look into the details of air sealing OSB more thoroughly as it's just been a concept to me up to now. I will be framing so I can certainly make certain that the sealant gets used, but I suppose temperature may start to become an issue as well here. I just lined my concrete work up for the first two weeks in October which means framing will run into November.

Though I see that Contega HF can be applied at 14f and above. But it looks like it's about $0.30 to $0.45 a lf...

Do you run into issues with shear with a vertical OSB orientation?

Malcom,

OSB is available in 4'x10' sheets.

The durability of OSB as a smart vapor retarder is pretty robust compared to 2-mil nylon (MemBrain) or Intello.:-)

Fiberboard sheathing is a mature product that has been around for more than 60 years. It has a bit of R-value compared to OSB or plywood, and lower structural capacity than OSB or plywood (and comes in non-structural versions as well, but since the outer studwall is non-structural in your design you don't even have to think about it.) It comes in many flavors, asphalted versions are more moisture resistant than some others, but they're typically 15+ perms.

http://www.fiberboard.org/index.php?option=com_content&view=article&id=54&Itemid=60

http://www.bildrite.net/sheathing.htm

http://www.buildgp.com/regular-fiberboard-sheathing

http://www.blueridgefiberboard.com/premium-insulating-sheathing-energy-saving-r-values/

Very helpful, all, again thanks! It seems as though either of these designs would be good choices (based on edits mentioned in your comments) so I've got some thinking to do. The single stud wall version seems slightly more expensive but possibly easier to detail and figure out the loading conditions.

I do like the idea of the double stud wall and the cost efficiency but I 'm more worried about moisture related problems with this assembly (after reading some of the articles Martin published as well as a few others).

Not to be too discursive but what about the likelihood that our Zone 6 climate will become a Zone 5 during the lifetime of this building? Would that tip the scales one way or the other? If you believe in climate change, that is...

Although it's easy to predict that the climate will change, predicting the specific change(s) in a specific location is hard. The change might, for example, include greater extremes, both cold and warm. So I think the best way to factor that in to a building design is to err on the side of robustness. For example, wall designs that work well regardless of which side has higher temperature and humidity, and that have high enough R-values that you won't regret your decisions regardless of what temperatures and fuel prices and availability do.

As far as being worried about moisture in double stud walls, the smart-vapor-barrier-in-the-middle approach is quite robust, especially with a highly permeable outer sheathing. It's hard to think of a scenario in which is runs into trouble.

One other option for highly permeable sheathing is pine boards. In central VT there are small and medium size milling operations that sell rough-sawn white pine boards at low cost. The wood itself is substantially more permeable than OSB, in addition to whatever the cracks between boards add. It's also less susceptible to moisture damage than OSB. They are more labor to install, and they don't add as much structural bracing, unless you make them diagonal, which is even more work. Different inspectors and engineers say different things about the structural capability with horizontal pine board sheathing, but it's not your load bearing wall, no worries. You can also add diagonal braces in addition to the horizontal sheathing, and the double wall leaves room in the middle to do that without any complicated joinery.

You of course don't want to try to use them as an air barrier!

ps one small local mill in VT is Wrights in White River Junction, but depending on where you are there might be others who are closer, including folks who will bring a portable mill and mill up the trees you are taking down to clear your lot.

Thanks Charlie, I'll think about that. My Stepdad actually has one of those portable saw mills and many acres of trees up in the kingdom so that could be a good option. Was thinking of going up there to get our cladding.

In a zone 6 climate the IRC allows class-III vapor retardency on the interior if the exterior sheathing is as vapor permeable as fiberboard or exterior-grade gypsum (DensGlass, etc.) .

http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_sec002_par025.htm

I'm not sure if that would still be safe for 3/4" white pine plank sheathing, but maybe. Robert Riversong has built dozens of Larsen Truss houses in zone 6 with latex stained ship-lap serving as both siding & sheathing. He has claimed (without citing measurements or sources) that:

"Softwood lap siding has a vapor permeance of between 10 and 35 - with solid-color latex stain on both sides, about 5 perm."

His walls are insulated with cellulose insulation, which is somewhat more protective. I'm not convinced that his wall systems would never fail, but I've yet to hear of any failing. He does comply with the 1-perm interior side vapor retardency limit, despite the high permeance claims for the sheathing. ( I'm a bit curious about how his stackups fare with direct wetting of the exterior walls.) I'm unpersuaded that the vapor permeance of shiplap (painted or not) is anywhere near as high as claimed, but would be interested in ASTM E96 test data on sawn plank of different species & moisture content. (Can anybody point me to that data?)

Following up on the climate change comment, it may be good to anticipate some form of mechanical cooling down the road and I wondered if that would actually necessitate insulation of the service cavity?