Mitsubishi Multi-Split Poor Cooling Performance

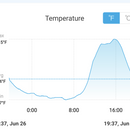

Last winter we had a manual J/S/D performed on our ~2500 sq ft colonial in New England and installed a Mitsubishi multi-split system. Specifically an MXZ-SM48NAMHZ and a ducted SVZ-KP30NA upstairs (attic) as well as downstairs (basement). Upon starting it this cooling season the downstairs has worked great holding a set temperature while the upstairs has been nothing but trouble. When it’s 76F degrees out (design temp here is 83F) the upstairs can’t keep a set point of 70F. See graph from my boiler controlling ecobee below (red plot is the master bedroom where the MKH2 controller is) – 70f_setpoint.png. The two threads below are very similar:

https://www.reddit.com/r/hvacadvice/comments/14rh7eb/mitsubishi_system_loses_cooling_after_an_hour/

Things I’ve tried in chronological order:

1) Put in “rock catcher” fiberglass filters in the event not enough air was getting back – no improvement.

2) Called the “diamond installer” who changed the temp control point from an average of the air handler and MKH2 to just the MKH2. Also added half a pound of r410a – no improvement. He also ran the unit in test cool mode and everything looked great but it was under a very low heat load at the time.

3) Verified the coolant numbers added are very close (within a lb of diamond builder).

4) Checked all the m-net addressing on the branch box as well as that the heads were wired to the same destinations as the piping.

5) Found the SW2-5 (“Branch Box connected”) on the outside unit was set to OFF but some threads said it should be on (why did the customer have to find this?) – no noticeable improvement.

6) Increased static form 0.5″ design static to 0.8″ – louder fan but no improvement.

7) With normal static set I let the upstairs heat up to 72F and cooled relatively easy down to 67F. When it got close it had trouble but it seemed to ramp down.

8) Put a data logger in attic. When the temp is 80F outside the gable vented attic can get to a peak of 112F (today in the attached pic it was 78-79F outside – attic_78f_outside.png)

I’m at a loss and down to the following options:

– Continue the saga with the “diamond dealer” and hopefully they will pull, weigh and charge followed by getting mitsubishi involved.

– Change the ETm temperature to 43F as other have done.

– Wait till another time when the unit is struggling and put it into test cool mode to see if it can keep up.

Help would be greatly appreciated.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

76 f outside with good solar radiation ? Depending on your attic insulation you might have issues with 70f setpoint.

Your unit aims at 30f delta t at any air handler fan speed. Measure it and if 30f or higher- it is good and you have insulation or sizing problem. Lower than 25-30f delta t- you have equipment problem.

I've been logging the supply temperature and the return temp (at the grills) as well. The supply temperature will be ~63F and the return is whatever the room temp is. At the same time the downstairs unit will have a supply temp of 49F.

Update: I measured the line-sets between outdoor unit and branch-box as well as the box to the two air handlers. When I enter these in diamond builder it seems the system is under charged by slightly more than 1 lb. Could this cause the issues I'm having?

Try changing the evaporator target temp (page 110).

If that doesn't work, you have low refrigerant. The only way to verify correct fill is by reclaiming and weighing, randomly adding weight doesn't do anything.

https://www.mylinkdrive.com/viewPdf?srcUrl=http://s3.amazonaws.com/enter.mehvac.com/DAMRoot/Original/10006/M_SERVICE_MXZ-SM_NAM(HZ)2-U1.pdf

I'm going to call the contractor today and have them come out again. I'll push to have them evacuate the system and refill to the correct amount. Would being a pound or two low have this effect?

In the mean time I'll try the evap temp change and report back.

Seems to me you have a leaky system!

They blindly added refrigerant on the first call and now you think you need more. Anytime they must add that indicates there is a leak that they are unwilling to fix. Demand they find the leak under warranty and insist all leaks are under warranty until you go 12 months without add refringent.

What is the temperature differential between the supply and return air? Any number under 15° is unacceptable and would indicate you are nearly empty.

Note the only accurate way to charge the system is to recover the existing charge and weigh it out and weigh back in the correct charge.

Walta

supply to return air temp is maybe 10 degrees.

“supply to return air temp is maybe 10 degrees.”

Maybe?

Did you use a thermometer to get that number?

Walta

Yes, I have wireless thermometers I bought for this problem. Right now the supply temp (at grill) is 61.0F, the return temp (at grill) is 70.3F. This temp at the supply will continue to increase through the hot part of the day. I can post a plot tonight.

Assuming the set point of the thermostat is set a few degrees lower than the 70° return temp. them the unit should be operating at its max speed and one would expect to see a drop of 15-30 °.

If the set point is 70° the unit may be operating normally and running just fast enough to keep the room from getting any warmer.

Walta

In this case it is very close to the set point. However, in the last few days when it's been hot (80-86F) outside. The air is never a 15-30F delta. After about 11Am the supply air is well into the 60's and doesn't come back down till later in the day.

Update: Couple of days ago when it was 82F outside and the temp started to drift up in the rooms I put the outdoor unit into cooling test mode. My understanding is this mode will operate at full capacity with an evap temp set point of 43F. The supply air temp and room temp dropped rapidly indicating the unit was not operating at full capacity or anywhere near it. Given this result the next day I set SW6-8 and lowered the ETm to 43F from 48F. The problem seems to have gone away although it seems less able to modulate down.

It seems that my unit wouldn't ramp up with the higher 48F evap target temp. Any ideas why this would be? Not enough return air? I have the installer coming out next week and I'm going to have him pull the charge and put in the correct amount from diamond builder.

I think this is a software bug but just in case, make sure to ask them to weight the refrigerant out. If you are missing refrigerant, you have a leak and need to find/fix before refilling otherwise you'll be back to similar issues next year.

Since it works in test mode, we can conclude it is a sensor or control issue.

You may find this thread interesting notably post 13 where Mitsubishi admits that they have released buggy software into the wild. If they have a defrost bug makes one wounder if they do not also have a cooling bug.

You may want to ask if your unit is running the latest software.

https://www.greenbuildingadvisor.com/question/mitsubishi-multisplit-hyperheat-excessive-defrost-cycling-and-long-heat-up-time

Walta

That's a good point I will ask. I don't believe I had that issue from the times I ran it in the winter but who knows.

It would be helpful to eliminate duct losses as a variable here. Ducted systems installed in unconditioned attics are almost always troublesome. I encountered one installation that cooled the house in winter heating and heated the house in summer cooling.

So I’d measure the supply temp at the unit to get an accurate delta across the coil. If that looks good then compare with what you are seeing at the registers.

Also worth keeping in mind that cooling output is rated at 80 degrees indoor dry bulb, so actual capacity can drop with a lower set point.

They're certainly pretty large, for the manual J I believe they came out to 5kBTU even with R8 insulation for everything up there. I'm going to have them check the ESP so they can hopefully check the supply/return temp at the same time.

While my attic venting leaves much to be desired I think the system working with the lower evap temp target indicates it is a control issue. My first thought is that it's not getting enough return air thus the coil temp reaches target too quickly and ramps down. I would have thought increasing the static 0.8" would have fixed it in that situation.