Detailing a Rainscreen with Exterior Rigid Foam Insulation

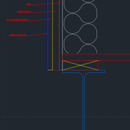

Here’s the situation. 2×6 frame with 1/2″ OSB. Grace envS WRB over OSB. Planning on 1″ of foam and we’re doing fiber-cement panel siding. At the bottom of the wall we either transition to stucco or to an exposed steel I-beam

Building is in Tucson.

So it seems all the details I see for rainscreens are not over exterior rigid foam, and many of them don’t have a vent layer, and that makes things frustrating. The fiber cement guys say to secure the cement into the wall framing, but with foam, osb and furring strips, you would need a really long nail to hit the framing and provide proper embed. Plus no one talks about the bottom and covering the exposed base of foam. I’ve attached a quick detail over the I-beam to illustrate the problems. So here are my questions:

1. What should I do here as I transition to the I-beam? Ideally I should cover the bottom of the entire wall assembly so I don’t see a hodge podge of OSB, Foam, etc. I’ll obviously have a bug guard for the vents(maybe a cross-ventilated furring strip or a plastic rain-screen vent from Fry-Reglet), but that stops at the foam.

2. If I secure the 1×3 furring strips to the framing with 3″ ring shank nails (or maybe long screws??) , can I just secure the fiber cement to the 1×3?

4. Some systems recommend treating the 1×3. I’ll do it if it’s necessary, but I loathe that copper-green crap..it gives me a headache. And because I’m using aluminum fry-reglet trim I’m assuming I’ll have to cover every single furring strip with a barrier like vycor. So is this necessary?

5. I’ve been frustrated enough to consider scrapping the foam and the furring strips and nail the fiber cement directly over the WRB/OSB. My wife tells me “we’re in Tucson, where it never rains and it’s dry”. Talk me off the cliff…

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Been quiet here? So I found this in a GBA article about rainscreens that might answer question number #2:

On securing the spacers to the framing and the cladding to the spacers:

The building code says that wood cladding fasteners must penetrate the studs, generally an inch of penetration (they weren’t really thinking of our high performance exterior insulation systems apparently). BSC is engaged in research to show that connecting the furring to the studs and the cladding to the furring introduces no shear issues. It is unlikely that your building inspector will fret over this, but BSC work to date has shown NO shift across the rigid insulation with any cladding systems with furring strips creating a vented, drained space.

So I think that takes care of #2. Any insight into the other three questions?

rszimm,

James Hardie has a technical bulletin describing how to specify the fasteners to be used when placed over continuous insulation.

https://www.aspyredesign.com/getattachment/6044fe6a-c287-40ae-b364-9b286178d124/19-jh-over-advanced-framing-or-continuous-insulation.pdf

I have found that their tech support people are pretty well-versed on the topic and can give you the appropriate fastening requirements over the phone.

Thanks. You know, I had trouble when I called Hardie on this topic a few months back. I told them what I was trying to do, and they told me to not use Hardie Panels for this, but really pushed their Hardie Reveal system (which is like triple the price). I was frustrated that they wouldn't answer any questions. For that reason alone I was leaning toward the Allura panels over the Hardie panels.

So I found the attached map on the Hardie web site. Given Tucson is in the "dry" zone, it seems to indicate that I can get by without a rainscreen gap or even a drainage plane WRB. In that scenario I'd attach the Fry-Reglet trim and the panels directly over the foam, and ash-can the whole furring strips concept. This honestly makes me a tad nervous, but many of my concerns disappear.

What do you guys think?

I am in the inland pacific NW and around here it's just sheathing, WRB and LP/Hardie/Other nailed on top of that. Zone 5 and we get 16" of rain a year on average. Not sure if that is best practice or not for this area. I think if you had real wood siding or shakes, a rainscreen product of some sort would be beneficial.

Pricing out a project for myself and looking at eliminating as much OSB/Ply as possible given the prices. Off the shelf, I can get around 3 sheets of R7.5 rigid foam board for the cost of 1 sheet of ply. Build up would be 2x4 framing with let-in ply panels at key spots and all windows. IRC allows for it and by my math I don't need many for my small project. Then Dupont Drainwrap as the WRB (tie windows in here) THEN rigid foam insulation.

Remaining question is should I do 1x3 wood rainscreen then Hardie/etc or just apply Hardie on the foam. Nail length, cost, etc is less with just putting Hardie on the foam, no air gap. We are using a board and batten look on the lower level, so the design is going to optimize the amount of Hardie used and where it hits on the studs.

So if I trust the Hardie map, it would seem in the pacific NW you don't need a full rainscreen. Just a drainage wrap (DuPont Drainwrap would suffice). So no need for a full rainscreen (1x3 furring strips).

Personally I'd resist the temptation to eliminate your OSB sheathing. I know it's insane right now, but it makes for a much more sturdy structure. My house is missing the OSB sheathing and just has foam outside of the studs with steel diagonal straps for shear. I hate it. We did a remodel and flashing windows was a nightmare (back then they let the foam act as a WRB as well.... WTF??). Anytime I go to mount something on the wall it's a pain because there's nothing to screw into (stucco on the outside).

Good point on the future fixes, etc. I think that if I did go sheathing all the way around (*working with an engineer on the ideas and sheathing may end up being the way to go) I will probably sacrifice the foam and those options and just tape the seams, rockwool in 2x6's and pay attention to airsealing, etc.

*My project is a garage with ADU above and the recessed shear panels, coupled with requirements for a small balcony, the garage door, the number of windows, etc the whole thing may end up being a ton of recessed shear panels... which at that point it's easier to just frame as normal. I may splurge and spend the extra $3 a panel for plywood ;)

rszimm,

Hardi maps aside, and given that there are some inland zones which are dryer, if there is one place in North America where full rain-screens are beneficial it is the PNW.

I'm with you: It's possible to eliminate exterior sheathing, but it sure complicates everything from flashing to trim work.

Thanks Malcolm. From looking at the Hardie map, my suspicion is that they're assuming you only need a full rainscreen where you have really heavy wind-driven rain (the Gulf States). It does seem odd to me that Seattle isn't in there though.

So what's your opinion of not only not needing a rainscreen, but not even a drainage wrap (given I'm in Tucson)??

Given current pricing, is it reasonable to put exterior (vs let-in) plywood where useful and use an extra 1/2" of foam everywhere else?

I'd just run some L-flshing along the bottom of the OSB with a 1." leg that will cover the exposed edge of the foam and vent screen I'd attach it to the OSB. Then tape the WRB to the flashing. Leave a 1/8" gap between to bottom of the flashing and foam for drainage. Have the flashing made in a color of your choosing.