Roof design and exterior insulation for cabin structure with wood beam ceiling

I am a complete novice and I am assembling a cabin structure in Los Angeles, CA to which I am planning on adding exterior roof and wall insulation. The interior of wood structure will be exposed, so all weather/vapor sealing will be on the exterior of the structure. Based on my research, I feel that rigid foam insulation will be the best fit for the roof and the walls, but I am open to using mineral wool boards if the case is made that they are a better all around alternative to achieve an R-value of R-38 for the roof and R-20+ for the walls.

I plan to use corrugated metal for the roofing system and need assistance in determining whether the metal corrugated roof be vented atop the rigid foam and weather barrier or unvented. Please share which of the following options you feel is the best design option between these three corrugated metal roof options:

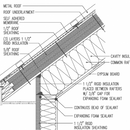

Option A: Metal Roof Design Unvented I

From bottom to top of roof system – Wood Sheathing (slats), Rigid Foam Insulation 3 x 1½” or 2 x 2½” Rigid Foam Insulation, ½” Wood Sheathing, Self Adhered Membrane, Roof Underlayment, Corrugated Metal Roofing

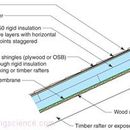

Option B: Metal Roof Design Unvented II

From bottom to top of roof system – Wood Sheathing (slats), Vapor Barrier, Rigid Foam Insulation 3 x 1½” or 2 x 2½” Rigid Foam Insulation, ½” Wood Sheathing, Self Adhered Membrane, Corrugated Metal Roofing

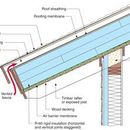

Option C: Metal Roof Design Vented Atop Additional Wood Sheathing, Weather Barrier & Diagonal 1” x 4” Wood Strips

From bottom to top of roof system – Wood Sheathing (slats), Vapor Barrier, Rigid Foam Insulation 3 x 1½” or 2 x 2½” Rigid Foam Insulation, ½” Wood Sheathing, Self Adhered Membrane, Diagonal 1” x 4” Wood Strips, Corrugated Metal Roofing

Option D: Metal Roof Design Vented Atop Rigid Foam and Weather Barrier

From bottom to top of roof system – Wood Sheathing (slats), Vapor Barrier, Rigid Foam Insulation 3 x 1½” or 2 x 2½” Rigid Foam Insulation, Self Adhered Membrane, Diagonal 1” x 4” Wood Strips, Corrugated Metal Roofing

I have attached pictures below but not all of the pictures match completely to my option descriptions above. There will be no interior insulation on any of the options, only exterior insulation. For the pictures that do not have a metal roof, please substitute the shingles for metal roof. There is no image for Option D.

Given the above selected option. How many layers of air barrier/vapor barrier/self adhered membrane should there be? 1 or 2? Where do they go?

What are the necessary qualities of the air barrier/vapor barrier/self adhered membrane and where should it go?

i.e. It has been recommended that a peel and stick Bituthene underlayment be used for the self adhered membrane. I would love your opinion of the necessary qualities of both these barrier and where they should be placed.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Corey,

Unless your area sees a lot of snow, there is no need to top vent the roof. The corrugated panels provide a fair bit of inherent ventilation.

I would just go with a peel and stick over your slats as both your air and wrb, rigid insulation, synthetic roofing felt (required by most metal roof suppliers) and horizontal strapping for your metal roof. No need for a 2nd layer sheathing.

You can use the exact same stack-up for your walls as well except the strapping now becomes the rain screen.

One thing to watch is your roof slats will leak a lot of air near the edges at the gap between them. The peel and stick won't seal this up. It is a good idea to put a healthy bead of caulk between the slats around the perimeter just above the walls as they are laid down.

Mineral wool makes sense mostly if you are in a wild fire area. It is expensive and a lot of extra labor to install.

HI Corey -

You are in a mild enough climate that heat rejection is almost certainly your biggest goal.

So, pretty much any of the assemblies you ask about--given that you achieve a continuous air control layer in the roof assembly--will work.

One point though: 3 of your 4 options includes a "vapor barrier" yet none of the images do. Not sure why you have included this component; in your climate and in these assemblies all that an interior vapor retarder will acccomplish is reduced drying potential to the interior--no need for this component.

And note that in each of the drawings you provided, the insulation and air control layer for the exterior wall comes up to meet the roof air and insulation control layers.

And in terms of your self-adhered membrane: generally best to protect this component with topside insulation. If you do choose to locate this component more to the exterior, make sure it is the "high-temp" variety.

Not in your question but something to consider: solar heat gain from any glazing is probably one of the next largest load to consider for your climate.

Peter

Thank you so much for your insight. It has been very helpful and I have made significant progress in the design of my small lincoln log kit-cabin wood structure, however, I still have a few questions that I could use some assistance with. Based on your recommendations and what appear to be common problems in high temperature climates I have decided on a basic design but I still have several questions regarding the design, materials and fasteners. Please find some drawings below.

For the roof:

Corrugated Metal Roof Atop Wood Sheathing, Weather Barrier, Poly-Iso Rigid Foam Insulation, Plus Rain Felt? and 1” x 4” Wood Rain Screen

From bottom to top of roof system - Wood Sheathing (slats), ½” Ply-Wood Sheathing, Weather Barrier (Water, Air and Vapor Barrier), Poly-Iso Rigid Foam Insulation 3 x 2” or 2 x 3” Rigid Foam Insulation, Synthetic Roofing Felt or (Breathable Membrane), Diagonal 1” x 4” Wood Strips, Corrugated Metal Roofing

Weather Barrier:

What weather barrier/wrap (water, air, vapor) do you recommend for the roof (Manufacturer and model)?

Should the weather barrier be water, air and vapor? I have come across wraps/barriers that are vapor permeable which I believe are to help prevent condensation. Is this something I should consider?

Would any of these above options cause a problem with condensation or reverse vapor drive? If so, what are your suggestions to mitigate this?

What is the purpose of the Synthetic Roofing Felt? Is this the best product for this application or do you recommend another product?

Fasteners:

Do you have any recommendations for manufacturers and models of the following?

- Rigid Foam Fasteners

- Screws to accompany the fasteners (5”, 6” 7” and 8”)

For the back exterior wall and half of the side walls:

Corrugated Metal Siding Outside Wood Sheathing, Weather Barrier, Poly-Iso Rigid Foam Insulation, Plus Rain Felt? and 1” x 4” Wood Rain Screen

From inside to outside of wall system - Structural Wood Siding, Weather Barrier (Water, Air and Vapor Barrier), Rigid Foam Insulation 2 x 2” Poly-Iso Rigid Foam Insulation, Felt Paper or Wrap ( Potentially Breathable Membrane), l 1” x 4” Wood Strip Rain Screen, Corrugated Metal Siding.

What is the purpose of the Synthetic Roofing Felt? Is this the best product for this application or do you recommend another product?

What weather barrier/wrap (water, air, vapor) do you recommend for the walls (manufacturer and model)?

Should the weather barrier be water, air and vapor? I have come across wraps/barriers that are vapor permeable which I believe are to help prevent condensation. Is this something I should consider?

Do you wrap the foam in a warp or barrier? If so, is there a manufacturer and model that you recommend?

If we do not wrap the foam, do we tape the seams and the edges? If we tape do recommend a certain manufacturer and model?

Would any of these above options cause a problem with condensation or reverse vapor drive? If so, what are your suggestions to mitigate this?

Fasteners:

Do you have any recommendations for brands or manufacturers of the following?

- Rigid Foam Fasteners

- Screws to accompany the fasteners (5”, 6” 7” and 8”)

There are a lot of details beside the WRB when it comes to your stack-up. Read through this as it has all the details including on how to deal with windows and doors.

http://cchrc.org/media/REMOTE_Manual.pdf

Cheap source for long screws is roofing supplier. You are looking for roofing deck screws. Box stores and your online places also carry them.