Sealing a ceiling

I am building a house with a unvented/cathedral ceiling and have read many valuable articles on this is site about how insulate. It is a hotly debated topic, with lots of options, but in the end, we kept it simple: Grace Ice and Water Shield on the ENTIRE decking outside and 11 7/8” I-beams with 10”+ of closed cell foam on the inside. The thought is put it on dry, seal both sides of the decking tight and be done.

The question is: if I leave a <1.5” air gap between my drywall ceiling and the ccsf (to run electrical and ultra-thin LED down lights and their j-boxes) should be be concerned about condensation in that gap space from the moist interior air? (or do I vent it somehow and make it part of the conditioned room?) Hoping that with 10” of ccsf, that there is no thermal issue from the outside.

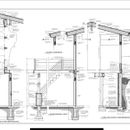

The house is being built in the woods of southeastern Ohio(Zone 5A). It is damp in the woods and we have all kinds of weather.(90s and humid in the summer and sub zero in the winter) The roof is 3/12 pitch. The roof is metal standing seam. The section of the roof over the great room and master bedroom is the cathedral ceiling and the rest of the house and garage is traditional attic.(see IMG_2029 for cross sections labelled Great Room and Master Bedroom for the concern areas and non-grey marked areas on IMG_2027) Subset of the original blueprints are attached.

Thanks

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You’re not going to have condensation issues with 10” of spray foam. You didn’t really need to put up that much either, but it won’t hurt anything.

There are some advantages to limiting air movement in that channel, but you should be ok either way.

Bill

Thank you. Follow up question- the foam insulation contractor is saying that they “never put more than 4” or so (two passes) in, that after that it is sealed and is recommending bat insulation after that. What are your thoughts on this? I was originally basically trying to “build my own sip panels” on this, and then decided to fill it all to provide extra insulation. Any concerns with mixing types of insulation? What is your recommendation for the foam ( I think I would like at least 6” or more, based on R-values). Any concerns with the bat insulation after it, it would be getting the moist air from the room. (Somewhat through drywall and ceiling lights (I have many 6” water led lights in the ceiling).

Thanks

Hi Kevin,

From an environmental perspective, the less closed-cell spray foam you use the better. And as long as you have the proper R-value of closed-cell foam against the roof deck for dew point control, you can fill the remainder of the rafter bays with fibrous insulation. Some builder compress batts into the space, to get a tight fit against the irregular cured foam surface. Others use dense pack cellulose, which will form to the contours as well. You'll find more in-depth answers to your questions in this article: How to Build an Insulated Cathedral Ceiling

OK thanks. Is there a table that shows me the depth of close cell foam that I need for it Based on where I live? Which is Ohio

In the US climate zone 4 sections of OH you need a minimum ~30% of the total R to be closed cell foam. In the zone 5 sections it's ~40% +. The green is zone 5, yellow zone 4:

http://bcapcodes.org/wp-content/uploads/2012/01/cz-map_ohio.png

Many HFO blown closed cell foams (the least damaging type) can be installed 7"-8" at a pass for the full R49 code minimum.

Most HFC blown foams (with a huge greenhouse gas footprint) can only be installed 2" per lift if going by the book, but some installers cheat on that. Don't let them install more per lift than the manufacturer recommends- it creates quality issues and can even burn your house down by overheating & igniting during the curing period.

So in zone 5A with 11-12" of insulation depth to play with you could do 4" of HFO blown foam (R26-R28) and 7"- 8" of 1.8lbs density blown fiberglass (another R28-R34) and have plenty of dew point margin, with almost 50% of the total R as foam.

Or for less money you could back off to 3" of HFO blown foam (R20-R21) and 8"-9" of 3.2lbs density blown/sprayed cellulose (R29-R33) and still meet or beat code-min on an R-value basis. With cellulose it's "safe" to cheat the R-ratio by a few percent, since cellulose will safely buffer and redistribute a fair amount of moisture without damage or loss of function. R20 foam out of R53 total would be about 38%, not 40%, but unless that metal roofing has a high solar reflective index the foam/fiber boundary won't be cold enough long enough to end up with soggy cellulose. The roof deck is completely protected by just 3" of closed cell foam.

For a sanity check on those assertions, see:

https://www.buildingscience.com/sites/default/files/migrate/pdf/BA-1001_Moisture_Safe_Unvented_Roofs.pdf

(Scroll down to Table 3 for the quickie analysis.)

Thank you for the quick response. They are unfortunately using hfc and talking 1.5-2” per pass so I am going to say 3 passes to get at least 4.5”-5+” of hfc so r24 to r30. Then they are talking 5.5” bat fiberglass at r20. Gets me 40 plus r value. Thought or tips on this config? Should I go back and ask about blown cellulose again? They said bats as they had a concern that blown cellulose would not stick, it would fall. ( won’t have drywall until later. ) I am assuming a faced fiberglass to also present a vapor barrier there?

Thanks

You can use insulation netting to support blown insulation prior to installing the drywall.

Bill

Ok, new challenge. In my unvented cathedral ceiling, the plumber just drilled a hole and put a vent pipe through the roof. My layers of 3:12 pitch roof are: Standing Seam steel, Grace Ice&Water over entire roof, OSB Decking, going to be 4”+ of closed cell foam then 6” unbatted fiberglass in between the 11” I joists.

They have “sealed it up fine” around the pipe as it goes through the ceiling and metal roof with a rubber boot and I assume caulk. Haven’t seen it personally yet.

What suggestions do you have for sealing around this? What should I insist that they do now that they have penetrated the roof that was supposed to be clear. (Venting was supposed to run up through the fireplace opening)

Thanks