Image Credit: Peter Yost

UPDATED on August 31, 2018 with information on vapor diffusion ports.

Although the GBA website already contains many articles on the topic, we continue to receive frequent questions about the best way to insulate a cathedral ceiling. It’s therefore time to pull together as much information on the topic as possible and publish it in one place, to clarify the building science issues and code requirements governing insulated sloped roofs.

In this article, I’ll attempt to answer the following questions:

- Does a cathedral ceiling need to be vented?

- What’s the best way to build a vented cathedral ceiling?

- What’s the best way to build an unvented cathedral ceiling?

- What do building codes require?

- What risky practices should be avoided?

What is a cathedral ceiling?

This article will discuss insulated sloped roofs. The methods described here can be used to build an insulated cathedral ceiling over a great room, a section of sloped roof above a kneewall, or any similar section of insulated sloped roof.

This type of roof differs from an uninsulated roof over an unconditioned vented attic.

A brief history of cathedral ceilings

Insulated cathedral ceilings are a relatively recent phenomenon. The craze for insulated cathedral ceilings (and great rooms) really took off in the 1970s and 1980s, when examples began popping up like mushrooms after a warm rain. In those days, most builders stuffed cathedral ceiling rafter bays with fiberglass batts. Sometimes they included flimsy Proper-Vents between the fiberglass and the roof sheathing, but often they just specified thin batts to ensure that there would be an air space above the batts for ventilation.

The cathedral ceilings of the 1970s and 1980s were thermal disasters. In most cases, these ceilings leaked air, leaked heat, created monumental ice dams, and encouraged condensation and rot. In many cases,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

528 Comments

Vented Over-Roof Hybrid

For Affordable High Performance...the closing sentence in Martin's Article is worthy of a Rant.

THE MOST UNDERAPPRECIATED BUILDING ASSEMBLY

Joe Lstiburek: "A vented attic, where insulation is placed on an air-sealed attic floor, is one of the most underappreciated building assemblies that we have in the history of building science."

If you do not care for affordable or buildable....

This BSC article is helpful

http://www.buildingscience.com/documents/published-articles/pa-crash-course-in-roof-venting

same article at Fine Homebuilding

http://www.finehomebuilding.com/how-to/articles/a-crash-course-in-roof-venting.aspx?langtype=1033

here is a good video and discussion about roof ventilation

https://www.greenbuildingadvisor.com/blogs/dept/building-science/lstiburek-s-rules-venting-roofs

I like Joe's comment #53 where he mentions the "vented unvented roof hybrid"

I think this is how many/most of the European Compact Roofs are Built

I think the same strategy(vented over-roof) could be used to improve the Marc Rosenbaum type roof.

I appreciate all the links above, but foam in Europe is far less toxic then it is here, not to mention that foam “still” traps moisture, and passive house has been building unrated or vented roofs in the East for a few years now without the issues in the article.. so NO, I don’t agree with foam or that air permeable insulation that apparently doesn’t work, is just not true… (See 475 articles)

I use in climate 4c, cellulose or mineral wool with or without an air channel with a inside vapor barrier like mento or Siga and an outer smart vapor barrier and sometimes Gutex as my exterior insulation thermal break.. it works just fine…

Image 1

Martin, I really,really like Image 1

(I also like that it is High Resolution)

GBA has posted it before for other articles.

The image shows an almost perfect storm (including the Ice & Water Sheild)

Do you know the original source for this photo and if it is possible to view other photos of this fascinating failure.

It is hard to tell exactly where the cellulose was and wasn't before the demo.....

but it appears that the areas that were packed with cellulose(lower left) show less damage.

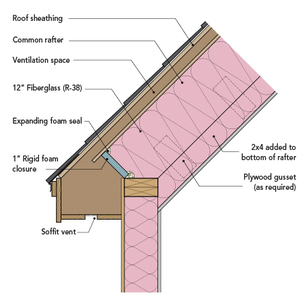

Rafter vent channels

I would add to Martin's list of materials for rafter vent channnels, fiberboard sheathing. I use I joists for vented cathedral ceilings and staple 1/2" fiberboard to the bottom of the top cord of the I joists. It can be ripped on a table saw and installs quickly, fiberboard does have a high perm rating and may allow small amounts of moisture to pass through into the vent space. I like a vented eave and ridge and have never had a problem with this assembly. A cathedral ceiling can be energy efficient if built properly with high levels of insulaton. You also get full insulation over the outside wall top plate which eliminates ice dam potential providing the building is airtight.

other photos of this roof failure

Hi John -

This project was in Vermont in a ten-year old home and as the caption indicates, the main culprit was leaky can lights in the cathedral ceiling. But the situation was exacerbated by an attached greenhouse, which communicated with the rest of the home, and a clothes dryer vented to the indoors during the winter. Interior relative humidity in the winter was running about 60 - 65%. The roof framing cavities were filled with cellulose; the cellulose was air permeable enough to allow the can light penetration and wiring run lead the leaking moisture laden air up the rafters to the hip.

I am including a photo of the solution: spray foam held down from the top edge of the rafters so that air can be drawn up from soffit vents to gable vents in the truncated attic cavity. This roof cavity is actively ventilated with a fan, not because the remodeler who did the fix was not confident about his new roof assembly, but because the owners were so gun shy of keeping their roof assembly dry.

Response to Doug McEvers - & a video for cold-climate builders

Doug,

Thanks for your suggested addition to the list of materials for making site-built vent baffles. I have edited the text of my blog to include your suggestion.

* * * *

On an unrelated topic: The Cold Climate Housing Research Center has produced a video (below) showing one method of building an insulated cathedral ceiling. The method shown in the video is particularly appropriate for builders in climates subject to ice dams.

Dense pack cellulose in vented athedral ceilings

Martin,

It seems if one were to use dense pack cellulose in a vented cathedral ceiling the vent channel material should be rigid enough to withstand the pressure. This would be a good insulation choice especially when using I joists, batt insulation is typically sized for dimension lumber and does not fill the space completely without modification.

Response to Doug McEvers

Doug,

You're right. In How to Install Cellulose Insulation, Bill Hullstrunk said that he has had good success with AccuVent baffles, which are evidently rigid enough to withstand the pressure of dense-packed cellulose.

A comment from Bill Rose

[Editor's note: Bill Rose just sent me the following comments in an e-mail; he included his permission to post the comments.]

A few things come to mind:

1) Simple roof geometry always permits venting, tortured roof geometry does not. So if we permit non-simple geometry, then we need solutions that do not rely on venting. Or we strictly forbid complicated roof geometry, and blame future problems on designers of non-simple roofs.

2) The lead photo shows ugliness right at the ridge. There are a lot of phenomena occurring there. A ridge is actually a corner, with all the effects of corner geometry (change in film resistance, radiant reflections, shape factors, etc).

3) Ugliness right at the ridge also prompted an inquiry about still-air stratification. How do lighter molecules like water vapor stratify against the heavier air molecules? I'll leave that as a homework exercise (it's a neat one). Short answer is that buoyancy plays a big role in air movement, but stratification of still air does not.

4) Have there ever been moisture problems in any roofs caused by effects other than, first, roof leaks, and second, air flow of one kind or another? My limited experience (honest!) is that airflow always plays a role in problematic roofs. And if the answer is that air flow from below is always a partial culprit, then are we so sure of our roof-venting skills to make sure that our vent strategies provide pure dilution and play no role in inducing flow?

I forget where you leave things in the post, forgive me. But the "tipped-up commercial foam-based, no air-path sandwich" is a good approach, a keeper. I stop taking bets on cathedral ceilings that use venting in other than simple, straight-run, air-tight-underneath conditions.

-- William Rose

Response to Bill

Bill,

Thanks for your perceptive comments. I will edit my blog to reflect your point about roof geometry.

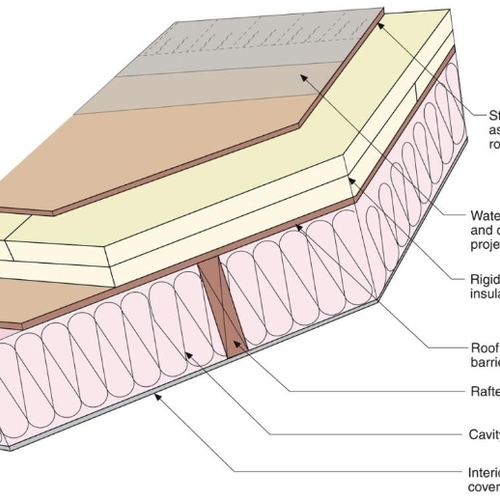

Air tightness

As Bill Rose notes, air tightness of the assembly, both inside and out, is of critical importance - we need to stop the air flow. Therefore I'd propose an assembly that utilizes materials meant to provide air tightness while also maximizing the drying potential of the roof assembly. The detail illustration I've attached shows such an approach. Solitex Mento 1000 membrane is used on the outside of the insulation - a vapor open, yet water and air-tight material - with vented cavity above - allowing for maximum drying out and preventing any wind/air penetration of the insulation. On the inside is Intello Plus, an air-tight membrane with vapor control intelligence - being vapor closed in winter and vapor open in summer - and protected with a service cavity. (Full disclosure, we are now supplying these products to the American market at http://www.foursevenfive.com.) A robust air-tight insulation assembly that doesn't require foam.

Response to Ken Levenson

Ken,

Thanks for posting the detail. Two comments:

1. Your suggestion is only a slight variation on a detail that is already discussed in my blog, namely cellulose installed with a vent channel between the top of the cellulose and the roof sheathing. You’re just using an air barrier material instead of cardboard, plywood, or fiberboard sheathing to separate the cellulose from the ventilation gap.

2. I think your proposed detail would be difficult to build. How easy is it to balance on the rafters as you install the membrane, presumably with staples, and then install the 2x2 spacers, presumably with nails or screws, all without putting a foot between the rafters? I wouldn’t want to do it.

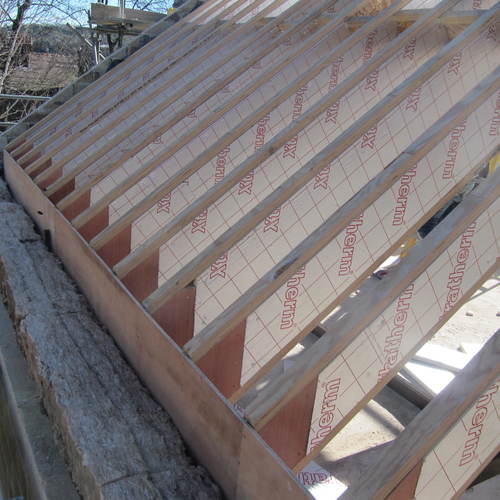

We just did exactly this for two days — stapling Solitex Mento Plus overtop TJIs spaced 16" and 24" OC atop a two-floor residential build, followed by 2x strapping parallel to the TJIs and then another layer perpendicular for a 3" ventilation channel. The risks were high and required extreme focus maneuvering around the TJIs but we felt it was worth it to have a solid air barrier on both sides of the insulation bays. Everything got much easier after the first layer of strapping was on.

vent channels and installs

Martin,

My sense is that if we are worried about air leakage compromising the insulation's effectiveness, vent channels are problematic.

Regarding installation: While it's been successfully installed in Europe for many years, we've just gotten the material, and so we look forward to getting it on a job site soon and actually installing it - and of course, reporting back how it went.

Vent channels

Ken,

I am with Martin on this one, your detail is labor intensive for little if any gain in my opinion. The vent channels we describe can be done after the roof is on from the underside (dry side). For those of us building in a cold climate this is a huge advantage, we spend as little time as is needed on the roof. A lot of new products out there looking for a home with some tough construction details to make them work. Your system as I see it would negate the use of dense pack insulation.

That’s the problem, labor intensive? Ya can’t get something for nothing…the work that passive house accomplishes is way beyond what you do now, hence this discussion!

Robert,

The discussion above -- between Ken Levenson, me, and Doug McEvers -- isn't a debate about "passive house" versus "non passive house." It's about two different methods of creating a vent channel above the insulation layer in a cathedral ceiling.

One method is the traditional American approach, involving the installation of vent baffles under the roof sheathing. The other method is a method used in some European countries, involving stretching a membrane above the rafters before any sheathing is installed. Either method can work fine for a passive house, or for a house that doesn't achieve passive house standards, as long as the installers pay attention to airtightness.

The debate concerns whether it's difficult to balance on rafters while securing membrane, compared to working from the inside.

new products

Doug,

Admittedly these are new products for Americans but they've been used successfully in Europe for years - so not really new. It will be interesting to see how the installation is adapted to our market. I can say we are not selling these products at arms length, we are working closely with the architects and builders on these projects. Like I mentioned, we look forward to reporting back from the field.

Regarding dense pack cellulose: not sure why dense pack would be negated - I think it perfectly suited.

thanks

Thanks for the summary of this condition. Makes a good reference point.

I like the detail provided but I wouldn't call that a cathedral ceiling condition as it includes ceiling joists spanning at the bottom of the roof rafters. I would call this an insulated attic.

Yes a cathedral ceiling detail would be very similar but the challenge of many cathedral ceilings is the added structural elements, electrical boxes, and the desire for wood board ceilings all which start compromising the drywall layer which in your detail is used at the air barrier.

Where are failures

I have built dense-packed unventilated roof assemblies several times without problem. Of course I haven't torn into them either. I would like to see more examples of failures in these kinds of assemblies if they're out there.

Vented ridge only

I have to wonder if the failure in the photo would have occured if the hip and ridge was vented and everything else the same?

Dense-packing accuvent

I was skeptical of Bill Hulstrunk's claim that AccuVent baffles could withstand being dense-packed in an enclosed cavity. So at Bill's suggestion Jim Millhouse (also from National Fiber) and I ran a couple of 'tests'. Bill was right, and the results weren't ambiguous. During the process the baffles showed few signs of deflection.

To be clear, we tested the AccuVent cathedral ceiling extension, not the standard AccuVent shown in Joe Lstiburek's Fine Homebuilding article on roof ventilation. Also, a small amount of material ended up on the wrong side of the baffle, which probably means folks would do well to follow Martin's advice on sealing them during installation.

About "Where are the failures?"

Dan,

I agree with you: I'd like to see more information on this issue. I'm not aware of any failures that have occurred in properly dense-packed unventilated rafter bays. The Building Science Corp. people refer to a failed roof that, if memory serves me, was a low-slope or flat roof with many peculiarities -- not a typical installation.

I suspect that Bill Rose is right: all of these failures involve moisture that is carried by moving air. These are not diffusion failures. If the rafter bays really are properly dense-packed -- a big if -- the chance of air movement is very low.

I think that people who write building codes are concerned that, if the code allows unvented rafter bays to be insulated with cellulose, failures will occur due to sloppy cellulose installation. Some installers will fail to dense pack every cavity, and there will be rafter bays with air movement, and we'll be right back to having problems with sheathing rot.

But if the installer is conscientious, and the rafter bays really are dense-packed, my guess is that everything will be fine.

Why not just do it right plus

Why not just do it right plus build with pressure treated roof sheathing. Even standard plywood can handle wetting cycles many times more than our number one super inexpensive OSB.

Any home being built better than the absolute minimums should at the very least not use OSB for roof sheathing. Imo

Concerning post #19

Martin,

Perhaps your "memory" is from Joe's Don't Be Dense Insight and Bill Hulstrunk's comments

see post #9

https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/19174/joe-lstiburek-says-dont-dense-pack-unvented-c?page=1&cm_BOqHX%24B7W8pUB8eKwgDiDDMa_B7W8pUxeh-0=1319665667

Plywood is better than wuzwood

It won't/didn't save a bad design like Image 1

Thanks

John

Thanks for finding the thread above...note that in post #17, Robert Riversong talks about the "vented over roof". I agree with you that this method deserves some attention for cathedral ceilings.

Looking at the fatal pic I

Looking at the fatal pic I feel there might be a simple though unorthodox solution. All the rot from warm wet air meets cold wood is right close to where a vented hip may have averted all and WITHOUT vent chutes.

So a hybrid approach needs to be investigated. Dense packed cathedrals with warmside ridged foam to add R, taped, no recessed lighting or other air paths and then belt and suspenders... Add venting even though there is no normal 1" vent path.

Doug... For some reason I did't see your post #17. Looks like two of us at least think there might be a very easy inexpensive solution.

aj builder

The main flaw in this roof looks to be the ice and water membrane at the highest point in the rafter bays. Would just regular felt paper have allowed enough moisture to dissipate through the roof sheathing avoiding rot?, I sort of doubt it. Plywood clips do give a bit of spacing between 4 x 8 sheets and depending on the location may have helped with regular roofing felt. There had to be some major air leaks in the air barrier to show this kind of damage. I am a plywood devotee and never use OSB anywhere but I think under the same conditions plywood would have failed also.

Whew, I'm confused now.

Hello all,

I thank you for this impeccably timed blog, as I am currently framing my semi-basic cathedral ceiling hip roof (with short ridge). I would like to describe my detail and try to understand where I am on the right track and more importantly, where I will have failures. Hope I can amuse some of you...I feel like the more I try to address a concern, the more of a concern it becomes, and I certainly don't want to take great time, care, and detail to facilitate the demise of my roof.

The existing: hip rafters, ridge, continuously connected top plate of wall perimeter are all i-beam construction, welded together & to each adjoining member. Remaining space is filled with dimensional 2x12 @24" o.c.

The plan: Part A: I came across 1" Dow rigid foam backed 5/8CDX for the same price as the bare CDX, and I plan to double it up like a SIP, installing the bottom sheet foam side up and the next sheet on top (staggered of course) with the foam facing down, giving me 2" of insulation between the plywood.

Part B: Install ice/water shield over the whole roof.

Part C: Install treated 2x4's from eave to ridge, long bolting into each respective rafter.

Part D: Either notch the treated 2x4 spacers for fitting 1x4's horizontally across them in order to ...Part E: Install metal roof over this.

My understanding as I read this blog is that I do not have to worry about creating an air channel above the sheathed portion because of the rigid foam. So simply install the metal roof on top of the ice/water ??? Will the properties of the metal cause condensation on the backside without sufficient airflow?

Thanks for your input.

Response to Deniz Bilge

Deniz,

1. You are building an R-10 roof. That's not much insulation; as far as I know, it won't meet code anywhere in the U.S. Where are you located?

2. It sounds like you are using steel beams to frame your hips. As I'm sure you know, these steel beams are thermal bridges. All insulation has to be on the exterior side of the steel.

3. Using continuous Ice & Water Shield is sometimes risky, but it's OK if you are following the PERSIST approach and putting all of your insulation on the outside of the peel-and-stick. The method can work, but you need much more foam on the exterior of your roof.

Doug I agree, too many wrongs

Doug I agree, too many wrongs "overthinking" and overdoing. I once had to resupply a doctor building an aircraft with dozens of AN aircraft bolts because they were tightened to the point of breaking the bolts. Less is more sometimes... Along with the KISS rule.

Back to the vent idea. I really think venting a roof that is airsealed in the interior well and built without vent chutes is possibly the best way to build cathedral ceilings. I think vented roofs have too much airflow and aid interior air getting out in the first place wasting energy and moving moisture to where we don't want it.

Response to Deniz

If your climate is not too severe it's probably okay to have just the R-10 foam over the structural steel, although there's some risk that the steel could sweat in cold weather. I'm assuming you also intended to insulate the 2x12 joist bays to get your total R-value to a reasonable level. I'd suggest using asphalt felt rather than impermeable membrane, so the upper plywood has some ability to dry if needed. You are wise to include the vent space below the metal roofing.

Science-code disconnect

What a timely discussion for me!

I am building a forensic laboratory constructed in Massachusetts, and am having a difficult time reconciling applicable building code with my read of the literature pertaining to insulation and roof deck condensation.

We decided to forego ridge and soffit vents during framing and roofing, trusting advice that an unvented roof insulated with spray foam was the better option. However, subsequent research and first-hand experience examining aged polyurethane foam (in a different context) that reverted to a liquid phase due to improper mixing 20+ years ago leave me extremely reluctant to use spray foam insulation.

Heres a snapshot of the roof: 2 x 12 fir rafters (12/12 pitch), 3/4 inch tongue and groove plywood underlayment, Grace membrane near eaves/felt elsewhere, asphalt shingles. The only ceiling and roof penetration will be a plumbing vent (no can lights, ductwork, etc.). Radiant heat, room air conditioners, and dehumidifier to contain RH at or below 40% (a must for one of my spectrometers).

My read of the literature suggests a low to moderate risk of roof deck condensation for my building, which could be reduced and managed using airtight drywall installation and a low perm primer or paint.

However, the applicable code does not appear flexible, with respect to buildings like mine.

I would greatly appreciate recommendations from experts: bite the bullet and risk of spray foam insulation, or send the builders back up on the roof in December to cut ridge and soffit vents?

Thank you,

James

What about an insulated nailbase product like Cool-Vent?

Thanks for this great discussion!

I am designing a house and we are using cellulose in 2x12 roof rafters, and I came across a product that looked great. It is an insulated nailbase called Cool-Vent by Hunter Panels. It provides up to 25.6 R-value in foam insulation (in thicknesses up to 6" which include a 1" airspace and plywood) while providing a cooling vent under the shingles, and easy installation for the roofing with the nailbase. Is this a product anyone has used? And do you think it is a better solution than not providing any venting, but using layers of poly iso over the 2x12 rafters filled with cellulose - a hot roof?

Thanks,

Malka

Response to James Martin

Sounds like you have the framing and roofing in place. Your options are described in the article above--you can add venting by installing baffles below the sheathing to hold back the insulation, or you can install at least R-20 of air impermeable insulation. If you go with spray foam, choose an experienced installer who understands the effects of temperature and other factors that can lead to failure. There are many reports on this website about what happens when foam is installed improperly, and it isn't pretty.

Flat roofs, spray foam and vents

Many spray foam roofing contractors in our market are touting their ability improve efficiency on old hot tar and graveled flat roofs by adding 3 to 4 inches of closed cell spray foam. Most of these old homes are flat roofs joisted with dimensional lumber, with parapets and have stucco vents cut into the rim joists. It has always been questionable to me as to the effectiveness of the occasional stucco vent to ventilate solid lumber joists, but we see little to no rot failure in homes even up to 60 years old.

As the head of our local HBA, I have strenuously pointed out that foam over a vented flat roof assembly does not provide the insulation values promised. Some builders have suggested they could simply seal and stucco over the stucco vents and eliminate the ventilation. The problem is the rim joist is not insulated above the level of the ceiling's batt insulation and therefore creates a major thermal bridge, which could lead to condensation problems from the rsing moist air stack effect. Then they point out that the 3 inches of foam over the roof deck would keep the deck and joists warm enough to mitigate condensation.

I want to promote cost-effective efficiency in my market, but not at the expense of roof failure. We are a 5B climate zone with 6000 HDD, heating from mid-October to mid-April. We are also extremely dry at 7000 ft above sea level.

So the question is: seal the stucco vents and add the spray foam roof and don't worry about condensation? There is very little low-hanging fruit in our type of construction, especially on existing homes, which is why people are being sucked into the spray foam roof scam.

Condensation control

Martin, I think your note re: 2009 IRC table R806.4, min impermeable insulation levels req'd for condensation control in unvented roof assemblies per climate zone, needs clarification; you stated

"After you have installed the code-mandated thickness of rigid foam above your roof sheathing, you’re free to install as much fluffy stuff as you want between the rafters."

However, I presume those min levels are based on the assumption that total roof insulation levels are around code requirements given the climate zone, e.g R-38 for CZ 5 (roughly double the R-20 impermeable ins. above roof deck req'd). So if one were to create an R-50 assembly, they better be providing R-26 impermeable insulation above the roof deck. In other words--it's the proportion of above vs. below roof deck insulation that matters, not absolute R-value provided above, that determines condensation potential.

alternatives to spray foam underneath sheathing

for an unvented construction with no insulation above the sheathing, how about using wood fibreboard between the rafters directly below and in contact with the sheathing? All gaps between the boards and the rafters filled with expanding foam / sealant. You could then cover the rafters with rigid foam to bring your insulation up to required R level and reduce the risk to the rafters and sheathing, and then install your airtight drywall underneath this. Also you could install T&G OSB onto the underneath of the rafters with all joints / edges bubble glued before your rigid foam and drywall go on. This would be another air barrier in your construction, perhaps more reliable than the rigid foam and drywall alone.

Take another look at the no foam option:

Ken's detail (#10) does a good job of cold climate safety. It has what we are looking for: Good airsealing at the interior, fluffy stuff in the middle, and good drying channels for water vapor at the top. By changing from a low permeability sheeting to a high permeability membrane (at top) with venting above, there is no more concern for roof rot while at the same time wind washing is prevented in the bays by the air & water tight membrane with taped edges and seams. It appears to me to be a very durable assembly.

Changing the Intelo membrane to glued & taped OSB or Plywood with a service cavity below made of framing lumber does make the assembly much easier to build. You can now walk on the Plywood/OSB as you work since it is glued (thats why glue + Tape rather than just tape) and also supported by the service cavity (via perpendicular framing lumber).

This assembly was recently built just south of Portland OR. I posted it a couple of weeks ago. Here it is again (with the builders comments) I think it's a pretty straight forward build once you get past the idea of adding service cavities to your build.

"Albert, Mark and Michael,

Yesterday we blew the insulation and installed the SIGA Majcoat on the CAPACES Leadership Institute. There was more than 8,000 Cubic feet of insulation to install, so our insulators had 2 of their blower trucks and a good crew on site. They were blowing cellulose as fast as they could and the the rain was heading our direction.

Less than 45 minutes after the insulation was completed we had finished the Majcoat and were busy taping seams. Because there is an airspace above the insulation, I am confident that the small amount of moisture that got on the insulation will be able to dry to the exterior.

I have attached a few photos showing the installation process and the dried in roof. The roof sheathing plywood is going down as I type and the roofers will be here on Tuesday to install the membrane for the living roof."

Response to James Martin

James,

Q. "Should I bite the bullet and risk of spray foam insulation, or send the builders back up on the roof in December to cut ridge and soffit vents?"

A. Either approach will work, as long as you get at least the minimum code R-value for your roof, and as long as you use construction techniques that pay attention to airtightness. Most homeowners are happy with their spray foam jobs. Your decision depends in part on how important it is to you to avoid spray foam.

Response to Malka van Bemmelen

Malka,

Using ventilated nailbase panels is a perfectly good way to build a cathedral ceiling. The same rules apply as when using SIPs: be sure that the seams are sealed to be as airtight as you can make them, and be sure that the total R-value of your roof assembly meets or exceeds minimum code R-value requirements.

Response to Katy Hollbacher

Katy,

You wrote, "It's the proportion of above vs. below roof deck insulation that matters, not absolute R-value provided above."

From a building science perspective, you are, of course, correct. However, the code does not use building science methods. The code requirements are as I reported them. The proportion of R-value above and below the roof sheathing are not cosidered by the code.

The old Canadian rule of thumb -- at least 2/3 of the total R-value on the exterior side of the vapor barrier -- is a rough-and-ready way to address this question; it's also possible to approach the question by performing a dew-point analysis or a WUFI analysis.

In the real world, however, we're all interested in determining the actual risk and hearing failure stories. I haven't heard any failure stories related to the problem of "too much fluffy insulation below the sheathing in a roof assembly with 2009 IECC levels of rigid foam above the sheathing."

Your caveat is appropriate and conservative. For the vast majority of builders, however, the code requirements will keep roofs free of problems.

Response to Kim Shanahan

Kim,

My advice would be to seal the existing vents.

If insulation contractors in your area are installing 3 to 4 inches of closed-cell spray foam above the roof sheathing, you don't have to worry about condensation or moisture accumulation in your sheathing. You're certainly right, however, that you don't want to have any ventilation under roof sheathing that has spray foam above it.

Response to James Brown

James,

Q. "For an unvented construction with no insulation above the sheathing, how about using wood fibreboard between the rafters directly below and in contact with the sheathing?"

A. Your suggested approach probably meets code requirements, since wood fiberboard insulation isn't air-permeable. However, high-R wood fiberboard is not yet manufactured in North America, so the only way to get enough R-value using your approach would be to import the insulation from Europe. That's expensive.

Response to Albert Rooks

Albert,

I think that most contractors would worry about the buildability of your approach. The photo shows a low-slope roof over a flat ceiling; this allows workers to stand on the ceiling joists. If the roof were steep and high, however, they would have to balance their feet on the rafters while installing a membrane. This membrane needs taped seams. That's tricky, fussy, work to do without any roof sheathing. If you add fall protection equipment, it becomes even trickier.

Buildability

Albert,

Martin makes a good point.

the example you posted does look to be tricky and labor intensive.

Buildability and WORKER SAFETY matter.

Of course a high pitch roof is problematic with other Not-So-Buildable stratagems too.

I would rather be the contractor on Albert's roof ... at least I would probably survive the fall

Martin & John: Yep. Your right of course...

Magic bullet status is not achieved. It's a design for a low slope roof.

It's very much along the lines of Doug McEvers use of high perm fibre board to create vent channels above dense packed cellulose. The idea is that it might be a "quicker build" to stretch a membrane across the top, tape seal it, and then cross batten, vent, and then sheet for roofing.

Like Doug's design, the focus is on creating a high perm layer for drying to the exterior, that will still allow venting while blocking wind washing in the fluffy stuff.

The specific design shown was for a Passive House. The roof thickness & use of a service cavity might appear to be overkill for most projects, but if you want an airtight lid, a service cavity will get you there - permanently... And allow you to wire and light the interior.

Not really Vaulted

Albert, It looks like your example is a Flat Ceiling project ?

It looks like it could be used with vaulted ceilings... (scissor truss)

It looks like a lot of trouble for a flat ceiling....

You mention wind-washing ... but isn't that mostly an issue near the soffit area?

Thorsten Chlupp is in a much more challenging climate and he seems to be doing fine with simple loose fill on the attic floor....of course he is using "ample" amounts (cellulose galore)and he has baffles near the soffit.

Vaulted, compact, & sealed but drying

John,

Sure the example shown is for a low pitch (not flat) roof. But change it to a pitched roof less than 6-12 and the details are still a good method (I think). Regardless of how you assemble it, the idea is airtight on the bottom, fluffy stuff in the middle, and a high perm layer at the top that seals from the wind (and rain, and animals (to a degree), and bugs...) with venting on top of that.

It's certainly not limited to an R 80 Passive House roof. Take out the parallel chord trusses and thin it up.

Sure it's a lot of trouble. It looks like less trouble that the detail posted as example in the blog above and uses no foam... Which is a "biggie" for me.

Since you brought up Thorsten Clupp, think of it as his Arctic Wall on a pitch (new picture below & still no exterior sheeting. Just a membrane, in this case Siga Maijcoat... Amazing...)

He gets a bit more snow that needs to be shed from the roof than you might in Texas, so of course he builds a high pitched roof and puts enough fluffy stuff on the roof deck that we could both have a soft landing after jumping from Mt McKinley.

Since the point of the string is making roofs that don't fail, there are going to be assemblies that really work well but are a bit of a departure. If we had the absolute best practices that we could ever imagine, already in hand and on job sites, we wouldn't be here (at GBA) and Martin would have far less to do... I'm sure he would enjoy writing about facial cream since the building stuff has been all figured out!

JB -Greetings from Olympia!

-a.

aha.....Parallel Chord trusses

Ok. Albert.... I understand now

I thought I was looking at conventional raised heel trusses with a flat ceiling.

Yeah... I could be more clear

JB- I really ought to post sketches as Ken did. It would probably save some trouble. For me this was harking back to the compact roof string.

Experience in Yukon

I have built log homes in the Yukon Territory in northern Canada for 30 years. Most log buildings have cathedral ceilings. Most of the roofs we have built are as follows (from the bottom up): log purloins, nominal 2" (2x6) t&g decking, 6mil poly, 1 1/2" extruded polystyrene foam, 2x10 rafters on 24" centers, 7" fiberglass, 2x4 strapping, 7/16 OSB, underlayment (15 lb paper, 30lb felt, or now we would even use ice and water shield). There would be about an inch of air space below the strapping for both vertical and horizontal air flow. All roofs are vented with strip vents at the eaves and vents in the soffit (2x6 t&g) at the peak at both ends. I would disagree that venting is not needed if you stop the airflow on the warm side, for 2 reasons. First it is very difficult to stop all airflow, especially with conventional traditional practices (ie chimney and plumbing vent penetrations through the roof) We have several techniques developed over the years to seal the vb at the eaves and gables, but there are still nail penetrations through the vb. Overall I think we had very tight seals but one could never say airtight. (Then blower door tests would be pressurizing the building and seeing if it dropped at all, like testing your plumbing for leaks. The fact that we are talking air exchanges says we are not air tight.)If the warm side air barrier is compromised so much that venting creates a bigger problem then the horse is already out of the barn. When it is 70 to 80 degrees inside and -60 outside there is a pressure differential, a vented roof will let even the frost evaporate a little during the winter and will dry what little moisture there might be there out with the warm days of spring. The second reason is for keeping a cold roof surface. With 3 feet of snow (good insulation, as long as you keep it below freezing) and no ventilation just where is the freezing point going to be? Do you have 3 feet of insulation in your roof? No, so there will be times when the freezing point is above the roof, if this happens enough you will have an ice dam and a leaking roof. Even with 3 feet or more snow on the roof the only time one of our roofs will have and icicles is in the spring when the warmer days will start the snow melting and the nights are still freezing the water as it runs under the snow to the edge.

Unless one uses extreme care with the warm side air barrier and this includes knowing that all fastener penetrations are sealed as well you should assume some air flow. The installation referred to here with the ice and water shield under the shingles obviously made a better air barrier than whatever was on the warm side. But if there had been no recessed lights would it just have taken longer? IF it was tight enough that the minimal amount of moisture was able to evaporate and move out of the roof enough to keep humidity levels low enough to stop any mold and decay growth than it may have lasted for ever. But to be properly vented above the insulation would certainly help with the big IF.

Better check the walls too

If they were venting the dryer inside (code violation?) and have an attached greenhouse I bet the walls are moldy too. Start in the laundry room with its perfect moisture point source "dryer".

Can I get some more commentary on the "whole roof" of Ice & Water Shield? I think this had very little to do with the failure. The reason why I ask is I have a similar "whole roof" design coming up, HOWEVER, the rafter bays are all straight runs with soffit vents, continuous vent baffles (1/2" plywood) and continuous ridge vent. Dense pack cellulose, 2" XPS below 2x10's, air tight drywall (XPS could be sealed up too).

Thanks,

John

[Editor's note: Click "page 2" to continue reading comments.]

Response to John

John,

I used to work as a roofer, and roofs that are entirely covered with Ice & Water Shield make me nervous. I see this type of design as lazy and potentially problematic. A well designed roof shouldn't need a continuous layer of peel-and-stick, and the peel-and-stick introduces several new problems: the plywood has zero ability to dry outward, and future sheathing repairs become difficult.

I know that many people note that drying to the exterior doesn't happen with most types of roofing, and that's true. (The exceptions are slate, clay tiles, concrete tiles, and cedar shingles, as well as steel roofing over purlins.) But I remain convinced that the peel-and-stick is just one more way to push a roof assembly toward danger.

So, I believe that the best roof assemblies don't have peel-and-stick (except at eaves and valleys) and do have ventilation. These two measures provide safety.

Snow Country Cathedral Roofs

Dan Reams, thanks for your comments. I also live in snow country near Yellowstone National Park. I often have well over 3 feet of snow on my cathedral roof. I believe the dew point is often in the snow rather than in the roof. The R value of the snow is often near the R value of the roof. This can lead to massive ice dams. A simple thermal analysis shows that you cannot put a practical amount of insulation in the roof to prevent the ice dams and move the dew point into the roof. A vented cold roof is the only solution. Most roofers in the area use 100% ice and water shield. Of course, stopping air leaks is critical. A solution that works in areas with little snow may not work in snow country. Many articles I read in Fine Home Building and Journal of Light Construction do not adequately address deep snow on the roof.

Unvented cathedral questions

My home built in 63 here in Ohio has a cathedral ceiling with no ventilation. In fact there many cross-supports running perpendicular to the main joists and other framing elements that would make this unfeasible. So I want to make it an effective unvented roof.

Half of the roof has 2x8 joists and the other half has 2x12s. Right now there is a membrane covering (rubber) that's worked well for over 20 years but is showing signs of deterioration and might need replacing soon. Having done remodeling on the inside and walking on the roof I know that a lot of the sheeting needs to be replaced along with the little insulation that is there now. We've had condensation issues in the past so I now there are air infiltration and bridging issues. Any insulation will have to be done from above when I take the sheeting off.

After reading this article I have some questions. I was thinking that I would spray in cellulose from above, then put on 3/4 sheeting, then rigid foam, then the 1/2 OSB required for membrane roofing, then the membrane.

I read this "First of all, you can’t use air-permeable insulation (for example, fiberglass batts, mineral wool batts, dense-packed cellulose, or blown-in fiberglass) to insulate an unvented roof assembly unless the roof assembly also includes a layer of air-impermeable insulation (either spray polyurethane foam or rigid foam panels) directly above or directly below the roof sheathing."

Since I have the rigid foam above the cellulose should my idea work OK?

Response to John W.

John,

Your plan will work fine, as long as the layer of rigid foam on top of your roof sheathing has an R-value of at least R-20. If you are using XPS, you need at least 4 inches of foam. If you are using polyisocyanurate, you need at least 3 inches of foam.

You are in climate zone 5. I explained the minimum R-values for the approach you are taking in one of the paragraphs above, in which I wrote, "According to ... the 2009 IRC, “rigid board or sheet insulation shall be installed directly above the structural roof sheathing as specified in Table R806.4 for condensation control.” The table calls for a minimum of ... R-20 for Climate Zone 5..."

OK, I was figuring that the

OK, I was figuring that the total of the rigid foam + cellulose had to be a certain R-value in combination and had been thinking of using less rigid foam.

I've been reading about different kinds of cellulose. Since I'm installing from above would something like stabilized cellulose work since it has a little water added? I would imagine loose fill could blow all over the neighborhood! Also in the case of my 2x12 section of roof, would 11.25 inches of cellulose cause any sagging in the ceiling drywall? Does that cavity need to be filled all the way?

I notice the IRC you mentioned called for a vapor barrier for Zone 5. How could I handle this?

Thanks for your response Martin.

More answers for John W.

John,

Q. "Since I'm installing from above would something like stabilized cellulose work since it has a little water added? I would imagine loose fill could blow all over the neighborhood!"

A. You should only use an installation method that your insulation contractor is familiar with. Here in the Northeast, many contractors would probably fill your rafter bays using the dense-pack method after your new roof sheathing was installed. For more information on dense-packing rafter bays with cellulose, see How to Install Cellulose Insulation.

Q. "Also in the case of my 2x12 section of roof, would 11.25 inches of cellulose cause any sagging in the ceiling drywall?"

A. Again, talk to your installation contractor. In most cases, you should be fine -- but the answer depends on the skill of the installer.

Q. "Does that cavity need to be filled all the way?"

A. Ideally, yes.

Q. "I notice the IRC you mentioned called for a vapor barrier for Zone 5. How could I handle this?"

A. There is a code requirement for a vapor retarder in some types of assemblies, but there is no requirement for a vapor barrier. Your layer of rigid foam is already a vapor retarder. No further vapor retarding layer should be installed.

Thanks again for the answers.

Thanks again for the answers. Now I just need to find an installer in this area who knows what they're doing (so far it's been iffy)!

Zip Roof over 16" Heeled Trusses

Martin,

We had a Zip Roof installed and a metal Roof placed over it. The roof assembly is not vented and taped all around the soffits. Ideally I'd like to pack the entire cavity with blown cellulose. This string of conversations is giving me pause for thought. If I dense pack the ceiling right to the sheathing, will I incur condensation problems? I'm right on the Zone5/6 line in Southern NH. My intention is to control Indoor Humidity with a Panasonic WhisperSense Bathroom Fan With Motion & Humidity Sensors - FV-11VQC5. Can condensation be dried to the Interior?

Zip Roof Assembly

As in this.

Response to Jim Peck

Jim,

Your proposed assembly is a code violation. If you want an unvented roof assembly, you need to keep the roof sheathing warm with spray foam or rigid foam. Cellulose insulation is classified as an air-permeable insulation and can't be used in such a roof assembly.

The danger is that interior moisture will migrate to the cold sheathing, leading to condensation or moisture accumulation.

To comply with the code -- and to adopt a building system that is less risky -- you need to either include ventilation channels or you need to install a layer of spray foam on the underside of the roof sheathing, following the guidelines explained in the article on this page.

Now that I have explained the right way to do it, I will also let you know that many people have done what you propose. A few cellulose insulation dealers, including Bill Hulstrunk, claim that you can get away with omitting the ventilation channels if you do a perfect job of dense-packing the cellulose.

Why risk it, though, with a new construction job?

What formula to calculate the

What formula to calculate the amount of ventilation?

Response to Jim Peck

Jim,

Here's the standard answer for those who need to comply with most building codes (the answer comes from an article by Mike Guertin):

"The standard roof ventilation requirement used in building codes and asphalt roofing manufacturers calls for 1 square foot of "net free ventilation area" for every 300 square feet of ceiling area (attic floor area) when vents are evenly divided — half of them high on the roof at the ridge, gable, or a high roof, and half low on the roof at the eaves. The alternative is to vent only with low (soffit) vents, by doubling the "net free vent area" to 1 square foot per 150 square feet of ceiling area.

"All manufactured roof venting products (soffit vents, venting drip-edge, gable vents, roof vents, and ridge vents) are labeled for "net free vent area." In the case of soffit vent strips and ridge vents, this capacity is listed in square inches per linear foot. For fixed-sized units, the capacity is published for the entire unit. Often it's necessary to convert the square footage of vent area to the published net free vent area in inches to make sure you are meeting the requirement.

"For example, a house with a 28-foot by 40-foot ceiling has an area of 1,120 square feet. With soffit vents only, you'd divide that area by 150 square feet to come up with the "net free vent area" in square feet (1,120 / 150 = 7.47 square feet). But because the net free vent area for most vents is listed in square inches, I find it easier to convert the calculated square foot vent area into square inches. There are 144 square inches in a square foot (12 inches x 12 inches), so I multiply 7.47 x 144 = 1,075.68 square inches of net free vent area. Using a strip vent product listed for 9 square inches per linear foot requires you to make only one simple division calculation: 1,075.68 / 9 = 119.5 linear feet of vent."

Venting

Thanks Martin,

I seem to recall this but, it has been awhile. Seems there are several options for us here. Thanks for all your help and the refresher. Once again I celebrate the useful dissemination of knowledge in this technical age vs hunting for a book.

Unvented Cathedral questions

Martin,

Excellent article and discussion. I have a question about an existing unvented attic assembly. The rafters are 2x4's and the bays between them are completely filled with closed cell spray foam. I would like to add two 1in layers of polyiso towards the interior of attic and then cover with a vapor open membrane to airseal the assembly. This assembly seems like it would have poor drying potential and as such taping the seams of the polyiso seems like a bad idea. The interior covering would be either T&G planks or plywood. I am located in zone 6.

Thanks for your posts and articles

Response to Michael Collins

Michael,

You're right that this type of roof assembly won't dry to the interior. But it isn't supposed to. I would tape the polyiso -- the tape won't cause any problems.

Thanks so much

Thanks

Advice Needed - Retrofit Solution for 1915 House Zone 5/6

I have a series of questions that incorporate many of the topics that you have covered in these articles, but I am trying to apply them in a retrofit situation.

We're working on upgrading the energy efficiency, including added/updating insulation, for our almost 100 year old 2-1/2 story balloon frame house (stucco over lathe exterior). The walk-up attic will be utilized space. The location is southeastern Wisconsin, which puts us close to the borderline of zones 5 and 6. Ground snow load here is about 30lb/sq.ft.

Did I mention that money is tight?

Rafters are 2x4, 12/12 slope, and the roof is complicated with intersecting ridge lines, valleys and dormers. (The house originally had a cedar roof. The deck is the traditional spaced fir planks.) Due to the construction, there is almost no chance of getting adequate air intake via soffit vents. (On top of the layout issues, there are problems because all the spaces between rafters where they meet the top plate were bricked in, apparently at time of construction). Proper traditional flow-through underdeck roof ventilation will be difficult.

When we first looked into this project, the building inspector asked us to still use vent channels (cheap polystrene was OK) to capture whatever ventilation we could. (Note: Re-roofing is on the horizon. We anticipated installing ridge venting at that time, and maybe figure out a way to get around the soffit problems.) Rafters were furred down with 2x2's so we could fill the rafter bays with R-11 fiberglass batts against the vent channels, and then we planned to layer the underside of the rafters with 2" XPS to build up to a nominal R-21 and help limit thermal bridging.

I've started on that work, but I'm beginning to doubt whether this is the best way to proceed. I'm looking to improve things.

Q-1: Confusion over the relative merits of low/medium/high density fiberglass batts.

Would high density R-15 fiberglass batts, or even medium density R-13, be a significant improvement over the low density R-11 (beyond the nominal difference of their R ratings).

This is a hard one to figure out from the reading I've been doing. The question relates to how much (if any) the low density fiberglass loses insulation value due to convection during moderate to severe cold (wind-wash), and whether the medium (R-13) and/or high density (R-15) are really any better. The high density fiberglass seems like it should be substantially less prone to wind-wash, as it is substantially more dense, but of course just because that seems logical doesn't make it true! (It definitely costs a lot more, though!)

(Side Question - couldn't you just compress two layers of the R-11 together when filling a 3-1/2" deep space and achieve R-15 that way? Per the R-Value charts for compressed fiberglass, it seems like that should work, and then you might have a less wind-wash prone space? I ask because I've got a lot of R-11 on my hands that might not end up being used if R-15 is a worthwhile upgrade.)

Q-2: To vent or not vent the underside of the roof deck.

(Side note - as mentioned below, we hope to re-roof in the next year, so options open up then.)

If I'm already not going to get adequate under-deck ventilation due to the inability to get adequate soffit vent air intake, might it make sense to just skip the attempt at roof ventilation and maybe instead put 1" XPS in place of the vent channel on the underside of the current roof deck? (It's labor intensive, but you can achieve a pretty tight fit between the rafters.) It's a tempting idea, because that would bump the nominal R Value of the assembly to R-30. (From the top down that would be R-5 for the 1" XPS against the underside of the roof deck, R-15 for the fiberglass batts (assuming a switch to high density fiberglass makes sense) which will fill the remainder of the rafter bays, and then another R-10 from the 2" XPS spanning the underside of the rafters.)

From reading, it appears that trapping water vapor becomes a potential serious issue to be concerned about. The 1" XPS has a perm rating of somewhere between 1.1 and 1.5 (depending on what source you refer to.) The 2" XPS has a perm rating of around .7 If moisture can't easily get in from either the topside or underside, but can basically exit just as readily as it can enter, is that a more or less neutral situation?

Another issue that comes up in that scenario is whether that could promote condensation on the underside of the 1" XPS when it is cold enough outside because the underside of the XPS could be below the dew point?

Q-3: What to do when we re-roof.

As mentioned above, we hope to replace the roof this next year. If so, at that time I'd like to upgrade to either an unvented roof or if necessary a cold roof (a vented over-roof). (I don;t know that it matters in the equations, but we're looking at buying and installing stamped metal shingles. The goal would be to get an exceptionally long life span out of the roof, and to do so while putting much less weight up on those 2x4 rafters than would be the result if we used asphalt dimensional shingles.)

Something I saw in the Building Science dot Com article "A Crash Course in Roof Venting" by Joseph Lstiburek (see http://www.buildingscience.com/documents/published-articles/pa-crash-course-in-roof-venting ) looked like it might be applicable to our situation. In the article Mr. Lstiburek had a side bar titled "Master Class - Unvented Roofs", where he discussed three possible unvented roof approaches. In one of those he illustrated using a combination of insulation above and below the roof deck to achieve your total insulation requirements. His illustration shows a roof with 2" R-10 XPS on the top side of the deck, and R-30 under the deck (in the rafter bays).

That looks very appealing: go with R-30 on the underside of the deck at our house using a combination of fiberglass batts and XPS as I described above, and then add an additional R-10 (2" XPS) on the top side when we tear down and re-roof? Unfortunately that sounds like it's too easy.

Can we (does the code allow it)? Does it make practical sense? Are there pitfalls due to our climate? How might we have to modify that to fit it to out situation?

In the alternative, if we can't do a ventless roof that way, can we achieve our total insulation needs by combining the above and below deck R-Values if we top it all with a vented over-roof?

Thanks for your time and your advice! Dan

Response to Daniel Grade

Daniel,

You've got a lot of restraints, and those restraints are leading you to some convoluted thinking. Instead of advising you to adopt a series of compromises, I'm going to explain the right way to address your roof, even if the right way is expensive.

1. You should get an engineer to evaluate the safety of your 2x4 rafters. "Furring down with 2x2s" doesn't improve the ability of your 2x4s to bear the snow load. It's possible that an engineer will advise you to sister 2x8s or 2x10s onto your existing 2x4 rafters.

2. You have described a roof that is hard (or impossible) to vent, for two reasons: complicated geometry, and the impossibility of installing soffit vents. That means you need an unvented roof assembly.

3. According to the building code, an unvented roof assembly needs R-20 of rigid foam above the roof sheathing for Climate Zone 5, or R-25 of rigid foam above the roof sheathing for for Climate Zone 6.

4. Once you have R-20 or R-25 of rigid foam on top of your sheathing, you can safely insulate below your sheathing with almost any kind of insulation you want to use to bring your insulation up to minimum code requirements.

Good luck.

Response to Martin Holladay

Thanks for the input. I see a visit with a structural engineer and 35 square of polyiso in my near future.

On the subject of fluffy insulation, are there any sources you can refer me to which address the differences between low, medium and high density fiberglass batt insulation from the standpoint of loss of R-Value due to wind-wash (whether due to air infiltration or convection as a result of significant temperature differences front to back)?

Most of the information I run across seems to be from the cellulose industry that claims wind-wash is a big problem with fiberglass; and from the fiberglass industry which asserts that the cellulose group overstates the issue and that to the extent wind-wash occurs it is really inconsequential.

I have a lot of walls to re-insulate, and once the roof is dealt with I'll have rafter bays to insulate, and it would be helpful to have some insight into which type of fiberglass gives you what benefit for its cost.

The high density fiberglass is so much more dense than the medium and low density fiberglass that it seems like it should reduce the potential for convection within the batts, but at 2 to 3 times the cost of medium density fiberglass batts the gain may be nominal and not worth the added cost.

Thanks for sharing your expertise,

Dan

Second response to Daniel Grade

Daniel,

Ideally, you want to have an airtight barrier above and below your fiberglass batts. If you can achieve those two air barriers, then wind-washing isn't an issue in a roof like yours. (It can be in a vented unconditioned attic, of course, especially near the soffits.)

If you intend to build a ventilated insulated sloped roof assembly, choose a type of ventilation baffle that can be installed in an airtight manner. Site-built baffles are best.

I don't have any data from thermal performance tests of fiberglass batts that attempt to make a wind-washing comparison between (for example) R-11 and R-15 batts. But it stands to reason that denser batts will perform better. You're right that stuffing a fat fluffy batt (or two fat fluffy batts) in a small cavity can mimic some, if not all, of the benefits of a dense batt.

Response to Martin

Thanks for your response Martin. Would you still be happy to use that unvented method for a renovation situation where there is non-breathable membrane (eg bitumous 'felt') above solid board sheathing? So the build up is, from outside to in; tiles, battens, aforementioned felt, solid board sheathing, rafters with tight fitting wood fibre board between and below, airtight drywall.

Response to James Brown

James,

It sounds like you have an existing roof with tile roofing. I'm guessing that you're writing from Europe. It sounds like the insulation consists of "tight-fitting wood fibre board" between your rafters -- thickness and R-value aren't specified.

If you want to create an unvented insulated roof assembly, you probably don't want to disturb the tile roofing. That means that the most appropriate insulation would be spray polyurethane foam. Of course, the existing insulation should be removed before you install the spray foam.

However, I think you are wrong about your asphalt felt; I doubt if the felt is impermeable to water vapor. Most types of asphalt felt are somewhat permeable -- typically 5 perms when dry and up to 60 perms when wet. Since your roof assembly can dry to the exterior, you may be able to use cellulose or mineral wool insulation between your rafters, if local building codes permit the practice.

Proper vapor barrier for vented?

This article was EXTREMELY helpful, Thank you! I have one question about creating a vented assembly by making an airtght system with accuvents. If I do that then install fiberglass, then an interior vapor barrier (this is for zone 5-6) am I creating the risk of trapping moisture between the two barriers? What type of interior vapor barrier should I use, if any?

Response to Jaime Masick

Jaime,

U.S. building codes do not require the use of interior vapor barriers, even in cold climates. What they do require is an interior vapor retarder. This requirement can be satisfied with kraft facing on fiberglass batts or vapor-retarder paint.

It is far more important to have an interior air barrier than an interior vapor retarder. Be sure that you have created a good air barrier by sealing all penetrations and cracks.

For more information on vapor retarders, see Vapor Retarders and Vapor Barriers.

vented cathedral ceiling in climate zone 3, edge to zone 2

I'm opening up my house and installing cathedral ceilings, I just wanted to confirm my plan since I got second thoughts reading more and more about it. My original decision was to go with a vented roof system and R38C batts. I read a lot about the different methods and it still appears to me that this is the best. Livint in Atlanta GA we have to deal with both hot humid summers and cold winters, so humidity control is a problem, that's why I believe the vented approach is the best. Anyhow, I'm down to the rafters and roofdecking and furred out the existing 2x6 with 6" metal studs, so I have about 11.5" for insulation. Mt plan was to create a continuous ventilation under the roofdeck, my question goes towards to use baffles, xps board build baffles or insect screen nailed at furring strips to allow for the airspace. This is followed by either R38C or R30C depending on the baffle design. Next I want to cover everything with 1/2" XPS and taped seams to add insulation and guarantee air tightness as well as vapor barrier. No penetrations due to air tightness, so I go with indirect lights. Now the inside XPS will help with thermal bridging and help in the winter months to stop humidity to enter the insulation and condense at the roof decking, at lest by not using the baffles. If I use the baffles I would crate a condensation plane and trap any moisture in the fiberglass insulation. I've read a lot of problems that the baffles create. Will the air tightness on the inside that I'm planning prevent these problems? Should I rather use my insect screen baffle idea to let the insulation breathe? What will happen to this assembly in the hot humid summer, where it should be the other way around here in zone 3?

Should I use airtight baffles or not, I don't see a way to have moisture escaping in a assembly with airtight baffles, fiberglass and xps on the inside, no matter what the dew point will be inside this assembly and possibly create condensation that cannot evaporate without ventilation. It appears to me that XPS baffles or any baffles that are airtight just worsens the problem, am I missing something?

Response to Michael Meyer

Michael,

The point of the ventilation gap is not the encourage moisture to flow out of your ceiling. The point is to try to handle any moisture that makes its way there in spite of your best efforts to prevent any moisture from getting there.

You don't want to use insect screen, because fiberglass batts need to be enclosed by an air barrier on both sides. When the top side of fiberglass batts are subject to wind-washing, the moving air degrades the performance of the insulation. During the winter, the moving cold air pulls heat out of the fiberglass batts as it moves by. You don't want that.

So, whatever baffle material you choose, make your installation airtight. You can't make insect screen airtight. So use an air barrier material like plywood, rigid foam, or fiberboard sheathing.

If you want a vapor-permeable material that is still an air barrier, choose fiberboard sheathing. But use caulk around the perimeter, and tape at the seams, to be sure that the material is installed in an airtight manner.

Response to Kimbark Smith

Kimbark,

Q. "Does open-cell foam qualify as an air-permeable insulation?"

A. Open-cell spray foam is vapor-permeable but air-impermeable.

Q. "If I execute the unvented roof as designed and put 4 inches of polysio on the roof deck, can I then use open-cell foam between the rafters?"

A. Yes.

Does Open Cell foam qualify as an air permeable insulation

Zone 5/6, I am trying to upgrade my cathedral ceiling and only have 2 x 4 (real)construction. Rather than extend the rafters, if I execute the unvented roof as designed and put 4" of polysio on the roof deck, can I then use open cell foam between the rafters?

thnx

I assume using closed cell would create the dreaded sandwich?

Response to Kimbark Smith

Kimbark,

Q. "I assume using closed cell would create the dreaded sandwich?"

A. Yes indeed.

Hot humid climate-all metal cathedral roof-must use R-11 batts

Incredibly helpful (5*) thread. So, if you must use fiberglass insulation batts, and you dont have access to spray foam or closed cell boards, what do you do? I guess the key is to make it unvented and add in other air-impermeable layers.

I am about to insulate a new all-metal cathedral pitched gable roof in the Caribean. The plan is to fill the cavity between the 4" Z-purlins with R-11 batting (vapor side facing the living space). For additional heat conduction resistance we plan to roll another thinner (filleted?) layer of this batting over the top of the purlins (ie between the purlins and the sheeting). I am thinking of installing this upper batt with its facing towards the metal sheeting. We also plan to seal the underneath of this "insulated purlin cavity" with a poly vapor barrier sheet and then screw in sheetrock (to the bottom of the purlins).

The overall house is *continuously* well ventilated with lots of louvered shuttered openings (No AC). There is a 4 x 3 vented window high up on the back cathedral gable, allowing hot air to excape. Basically the set up is very different to your typical northern-US home, but could be relevant to a non-airconditioned "eco-green" South Florida dwelling.

This is where I got the above idea. It's the "Double Layer banding system."

http://steelbuildinginsulation.com/highr.html

Many of my neighbors here have cathedral ceilings, no attics and absolutely no insulation (basically they have aluzinc roofs on plywood with pine rafters). These high roofs are pretty cool, which is good as most of us cant afford to A/C. We wanted a metal roof specifically to avoid the termites that plague the latter roofs eventually.

1) Is my plan OK?

2) Will we need more air barriers (how about above the top layer of batting, just below the metal sheeting)?

3) (bonus) How would you go about installing this roof?

Answers to any of the above are very appreciated.

PJ

Response to PJ PR

PJ,

I don't have experience building in the Carribbean or building steel buildings, so I'm not the best person to comment. But here are a few reflections:

1. You don't want an interior vapor barrier. In a hot humid climate, the vapor drive is always from the exterior toward the interior (assuming your building is air conditioned). If your building isn't ever going to be air conditioned, the vapor drive will still be from the exterior to the interior, but there won't be much vapor drive. If you want any kind of vapor retarder -- and I'm not saying you need one -- it would go on the exterior side of the insulation, not the interior.

2. Whenever you install fiberglass batts, air barriers are much more important than vapor control. You need a good air barrier on both sides of your fiberglass batts. A material like MemBrain (with taped seams) is one possibility. Other materials that can be used to create an air barrier are plywood with taped seams or gypsum drywall.

Hi Martin,

Thanks for the

Hi Martin,

Thanks for the feedback. We will never A/C the building (it will be solar powered). The wind is pretty constant, but it is a humid environment, so moisture control is certainly on my mind.

You say "You don't want an interior vapor barrier," but you also say that "you need a good air barrier on both sides of your fiberglass batts." The latter would turn out to be an interior vapor barrier not so? Ie. If I install a polyethlene sheet between the bottom of the batting and the sheetrock [it would be attached to the purlins], wouldn't this be an interior vapor barrier? Maybe I'm not getting what you mean by an interior vapor barrier.

The other question I have is will the gypsum sheetrock be enough (do I need the polyethlene)?

Cheers ,

PJ

Response to PJ

PJ,

Q. "You say 'You don't want an interior vapor barrier,' but you also say that 'you need a good air barrier on both sides of your fiberglass batts.' The latter would turn out to be an interior vapor barrier not so?"

A. No. Not all air barrier are vapor barriers. For example, gypsum drywall is an air barrier, but it is not a vapor barrier. Similarly, MemBrain is an air barrier but not a vapor barrier. For more information on these issues, see these two articles:

Vapor Retarders and Vapor Barriers

Forget Vapor Diffusion — Stop the Air Leaks!

Q. "If I install a polyethlene sheet between the bottom of the batting and the sheetrock [it would be attached to the purlins], wouldn't this be an interior vapor barrier?"

A. Yes, it would. I don't recommend the installation of interior polyethylene in your climate.

Q. "Will the gypsum sheetrock be enough (do I need the polyethlene)?"

A. If your goal is to install a good air barrier, then drywall is certainly adequate, as long as you seal all penetrations to avoid air leakage. For more on installing drywall in an airtight manner, see Airtight Drywall.

Light on regarding vapor & air barriers

Aha....I get it now.

Our cooler mornings may make the interior of my metal roof sheeting to sweat slightly since it will be in contact with the warmer unvented fiberglass-insulated purlin "cavity" underneath. Once our hot Caribbean sunshine starts to kick in I want this moisture to dry and/or diffuse out of this cavity, through the gypsum sheeting, into the cathedral living space below, to then be blown out of my 4x3 gable window. A vapor barrier would completely retard this process. Finally, the reason for installing an air-sealed gypsum drywall is to LIMIT the amout of humid air that gets into the purlin cavity in the first place. Consequently, as much as possible of the hot daytime humid air is directed out of the interior building space by the Caribbean breeze flowing through the continously open shutters that I installed. How does that sound?

Aside: I wish I had access to foam spray or the foam boards. But we can only get our hands on double bubble or R-11 batts (the latter arrived today).

Finally (I promise this is my last topic). Regarding my fiberglass batts: Will the facing that comes with it retard the drying out process that I described above (does it matter what side I put it on within the purlin cavity?) and will 2 layers of R11 be too much to compress in my 4" purlin space (I realize that codes in the US call for more insulation, but I will have a good amount of cool breeze flowing through my house). The folks at http://steelbuildinginsulation.com/highr.html say I should filet an inch off the upper batt, concur?

Thank you Jedi masters at greenbuildingadvisor.....PJ

1st layer of R11 going on ...

Well the roof is going on with the first layer of insulation (on-top the purlins, under the roof sheeting). There appears to be enough space left in the 4" purlin cavity for the second layer of R11 to be installed without any modification. I realise however that, having been compressed for so long in these big rolls, the fiberglass may "swell up" over the next few days... We shall see.

Any thoughts about the paper facing? (see my post immediately above). Obviously (from the photo) the first layer was installed facing up. The second layer I propose to install face down.

The plan is to install it (from the inside of the house) about the same time the drywall is put up. I will instruct my crew to make sure there are no air pockets in the purlin cavities & no air flow into the latter. I will supply them with cans of great stuff to make sure they get to all the gaps.

Thoughts? ideas? PJ

Flat roof cathedral ceiling

We're going to give it a try. Existing is a fourteen year old roof with 2" of closed cell roofing foam with an acrylic elastomeric coating. Below is 1x decking and 2x4 rafters. Our plan is to put rigid board up between the 2x4's, caulk the edges, and then hang sheetrock. We'll air seal the one electric junction box for the room light. And cross our fingers.

This is in the San Francisco Bay area fog zone (a heating climate).

The one question: should we vent the space above the sheetrock to the interior?

Response to Bryce Nesbitt

Bryce,

Q. "Should we vent the space above the sheetrock to the interior?"

A. No, that won't be necessary.

Old cottage cathedral ceiling

I have a 50 year-old seasonal cottage in a northern climate. The simple 6/12 gable roof is composed of actual 2x6 rafters (24" oc), sheathed with 1/2" plywood and covered with asphalt shingles. There is no insulation in the ceiling and I suspect little to no effective insulation in the 2x4 walls. In the summer the heat gain inside makes living almost unbearable. I suspect that the biggest bang for the buck would be to address the ceiling insulation issue first, but would like to maintain the interior appearance. Would it be reasonable to strip off the shingles, lay down (in order inside out) 6mil VB, high density foam board (6 to 8"?), roof deck and shingles? Would it be better to strap under the new deck with 2x's from eave to peak to vent the deck? Is a separate VB necessary with that thickness of foam board? Any advice would be appreciated. Thanks.

Question: Bunkhouse

Client wants exposed cathedral ceiling (cool moist climate - Zone 5-6).