Minimizing Condensation Risk in Low-Slope Roof Assembly

I’m a little confused on what might be the best approach for minimizing condensation risk within my flat roof assembly. Details:

*zone 6A, Maine

*small addition, ~18×16

*unvented low slope roof, .75/12 pitch, EPDM

*hybrid assembly, with 4.5″ polyiso over the deck (~R28.5, not derated as it’s Thermax on the top layer.). Batts in the rafter cavities.

*3/4″ Advantech roof deck is sealed with Prosoco liquid flashing at seams

From my research it appears that a smart vapor barrier over the roof deck, below the polyiso, and wrapped up the roof edge blocking would be appropriate. Thus any condensation that might occur on the underside of the polyiso or EPDM could dry to the inside.

Questions:

Is this a good plan or is there a better way? Should I just skip this and tape the bottom layer of the polyiso?

The assembly will include a mechanically attached coverboard- won’t the long screws just make any vapor barrier ineffective anyway? Should I just seal up the inside edges of the roof blocking and diligently install an interior vapor barrier?

Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The 3/4" OSB is pretty much a smart vapor retarder already, you don't need another one:

https://www.pfsteco.com/techtips/pdf/TT_Permeability_of_OSB_2018

The important part is the air sealing, I think tape would be much simpler than liquid flash but liquid flash will work as well. The hard part is air barrier continuity to your wall sheathing, as you have it drawn the roof OSB is in the way. It might be worth it to stop the OSB about 1/2 way across the wall top plate, tape the OSB to the wall sheathing and continue with another piece from there to form the overhang. This might need beefier support for the overhangs.

Vapor barriers work based on surface area, if it covers 99% of the surface, it blocks 99% of the vapor flow, screw holes don't matter.

The 3/4" OSB is pretty much a smart vapor retarder already, you don't need another one:

https://www.pfsteco.com/techtips/pdf/TT_Permeability_of_OSB_2018

The important part is the air sealing, I think tape would be much simpler than liquid flash but liquid flash will work as well. The hard part is air barrier continuity to your wall sheathing, as you have it drawn the roof OSB is in the way. It might be worth it to stop the OSB about 1/2 way across the wall top plate, tape the OSB to the wall sheathing and continue with another piece from there to form the overhang. This might need beefier support for the overhangs.

Vapor barriers work based on surface area, if it covers 99% of the surface, it blocks 99% of the vapor flow, screw holes don't matter.

Thank you for your answer!

What R-value do you plan to use for batts? Because of the risk of long-term moisture damage, I would use R-5.5/in for the foam, regardless of what the manufacturer claims. At least 50% of the total R-value should be in the foam layer (for climate zone 6).

Thanks Akos and Michael.

Regarding R-value: I'm using the U-factor alternative equivalent approach (as Akos had once suggested and my code guy was amenable to). I don't plan to fill the entire rafter cavities so that the assembly is safer from a moisture perspective. Backing into an equivalent R-value for zone 6, I need to achieve ~R39 for the assembly. If I use R15 batts with insulation wires to ensure they are against the bottom of the roof deck, derate the polyiso, I'm at R41 for the assembly, with ~60% of the R-value in the polyiso. This also leaves open rafter space for wiring, etc. Sound reasonable or am I off track?

I've completed the overhangs. I extended the advantech continuously over the "bolt on" overhangs to ensure strength. I'm now prepping for the above deck insulation and EPDM.

My ultimate concern is moisture entering the roof assembly, from either the conditioned space below OR from roof sides. I'm concerned about moisture entering the assembly, condensing on the backside of the EPDM, and then making it's way back to the roof sheathing below.

Most concerning is the the wall where the roof connects to the house. The second floor bathroom is adjacent to this wall at the roof connection. I'm concerned moisture from the bathroom will be able to enter the roof assembly and condense.

This video got me on the path to consider the smart barrier over the roof deck (about 2mins in):

https://www.youtube.com/watch?v=LZSdQjGvL9k.

Your insulation plan seems reasonable. The foam will keep the sheathing warm enough that if a small amount of air reaches the sheathing, it won't condense. You still need drywall or something else to limit airflow, but I'm sure you're planning on doing that.

How would air get to the sheathing from the sides of the roof?

Does your bathroom have vapor retarders of some sort? An exhaust fan?

I only watch videos when absolutely necessary; apparently I'm getting old ;-) Perhaps you can summarize why you're including one. I can't think of any reason to use a variable permeance membrane (they're dumb, not smart!) over the roof deck.

"getting old"... I'm with you! And likely ahead of you ;-)

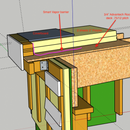

"How would air get to the sheathing from the sides of the roof?" Won't the perimeter of the roof, above the roof deck, be susceptible to air/vapor flow from the exterior into the assembly?...Which could condense on the backside of the EPDM, and get back to the sheathing? See arrows in the attached sketch.

"Does your bathroom have vapor retarders of some sort? An exhaust fan?" No real vapor retarders, other than paint, some tile. We do have an exhaust fan. Eventually, I'll install a humidity sensor controlled fan. It's #453 on my list :). It's an older, high humidity house and the bathroom is a humidity multiplier. The basement is on my project list a well, but that's further down on the fun-scale.

I think this excerpt summarizes the logic from the video for the above deck barrier for low-sloped unvented roofs:

(excerpted from https://www.abbae.com/wp-content/uploads/2020/04/RCI_33rd_Houston_TX_Trade-Show-AVOIDING-CONDENSATION-IN-LOW-SLOPED-ROOFING-ASSEMBLIES.pdf)

"In a low-sloped roof assembly insulation is often installed in the ceiling. The simple and obvious place to add a vapor barrier is below the insulation on the ceiling joist. However, installing a vapor barrier on the warm side of ceiling (below) insulation is the worse place to put it. Vapor barriers in the ceiling are difficult to install and almost always result in failures. This is because ceilings have many penetrations like canned lights, vents, pipe penetrations, demising walls, etc. Vapor barriers installed in the ceiling due to the number of complex conditions require high degree of skill and quality control which is often lacking. Instead, it is better to install the vapor barrier on the roof deck, under insulation and the roof where the conditions are more controlled. In these cases the vapor barrier is typically installed by the roofing contractor as opposed to thermal insulation or sheet rock contractor who does the work in the ceiling."

My goal is to get this right so that I don't have an expensive repair later.

Really appreciate your feedback.

I'll summarize my question in hopes of getting a few more opinions: Should the perimeter of unvented roof assemblies be air/vapor sealed? (ref. pic in post #6)

Steve, yes the perimeter should limit air and vapor movement, but not much air or vapor is going to squeeze between the sheathing and foil-faced foam attached tightly to the sheathing. Unless I'm missing something, I wouldn't worry about it.

I recommend moving "drying out the basement" way up your list. It has a huge effect on tightly-sealed homes. I'm in Maine and have the same problem; as soon as I finish replacing my front stoop that a delivery person put their foot through, it's next on my list. It's probably the most important thing you can do after having a watertight roof.

I agree that having a vapor BARRIER on the interior is a bad idea. But a variable permeance membrane is ideal--it limits how much moisture can get into the assembly, but allows it to dry if the moisture reaches risky levels.